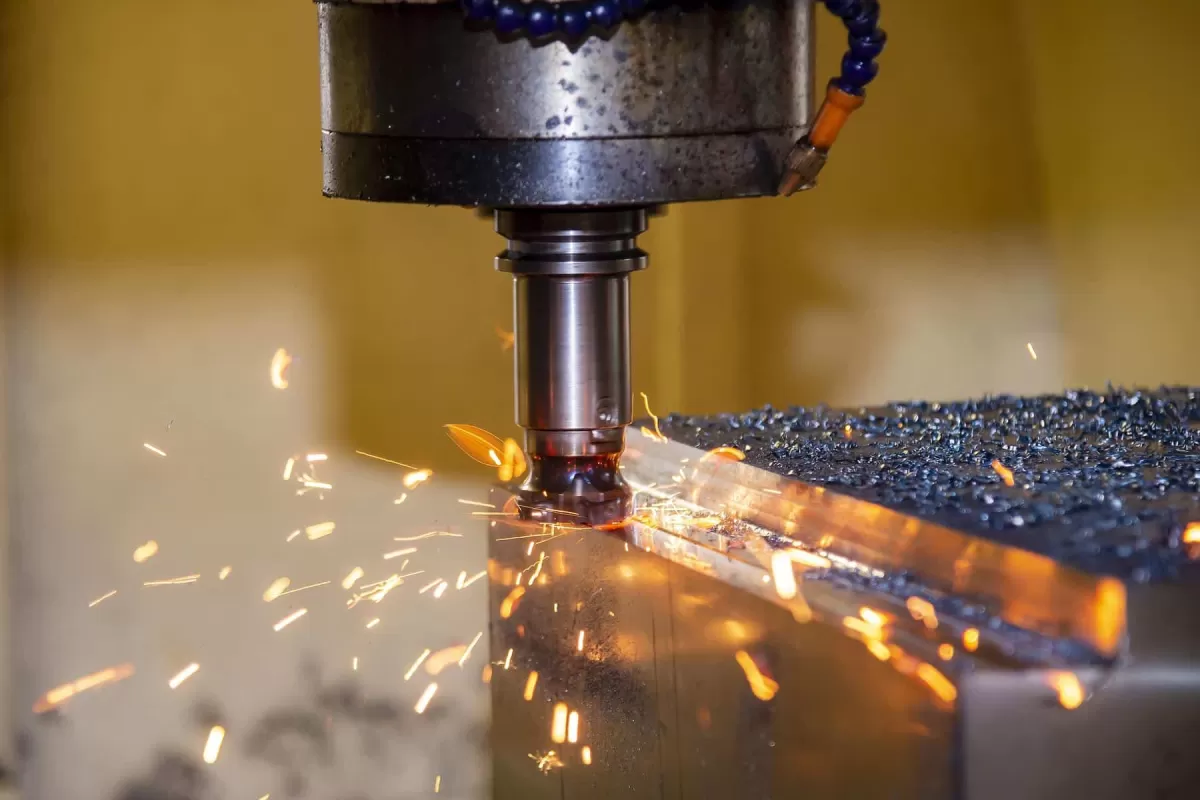

Why Design Matters for Low Volume CNC Milling

If you’re working with low volume CNC machining—meaning you’re producing anywhere from 10 to 10,000 parts—you probably already know it comes with a unique set of challenges. Unlike mass production, low volume runs don’t benefit from economies of scale, so every design choice can significantly impact cost, machining time, and ultimately, how well your parts perform.

Good design is critical here. If your part isn’t designed with CNC milling in mind, you might face higher costs, longer lead times, and even issues with part accuracy or durability. That’s where Design for Manufacturability (DFM) principles come into play. DFM means crafting your parts to be as easy and cost-effective to machine as possible while still meeting your functional requirements.

When you apply solid CNC milling design guidelines for low volume production, you can:

- Reduce setup and machining time

- Lower material waste

- Avoid expensive custom tooling

- Achieve better precision and quality

- Keep costs predictable and manageable

Taking the time up front to optimize your design for CNC milling not only speeds up production but also improves how the finished part functions. Whether you’re developing prototypes or small batch CNC production runs, smart design choices directly impact your bottom line and project success.

Key Design Tips for CNC Milled Low Volume Parts

When designing for low volume CNC milling, keeping things simple and practical saves time and money. Here are some key tips to follow:

-

Avoid Sharp Internal Corners

Sharp inside corners are tough to machine and can slow down production. Use fillets or rounded corners to make milling smoother and reduce tool wear.

-

Optimize Wall Thickness

Keep walls thick enough to avoid warping or breakage but not so thick that it wastes material or adds machining time. Consistent wall thickness helps maintain part strength and cuts costs.

-

Use Standard Hole and Thread Sizes

Stick to common hole diameters and thread sizes. This lowers tooling costs and speeds up production since standard tools are readily available.

-

Simplify Part Geometry

Complex shapes take longer to machine. Simplify the design whenever possible to reduce machining time and lower costs without sacrificing function.

-

Minimize Text and Non Critical Features

Adding text or extra details can increase setup time and tooling needs. Include these only if they’re essential for your part’s use or branding.

-

Choose Cost Effective Materials

Some materials are easier and cheaper to mill than others. Select materials that balance performance with machining cost to keep your budget in check.

-

Design for Standard Stock Sizes

Using common stock sizes for your raw material avoids extra cutting or waste, which helps reduce lead times and overall cost.

Following these CNC milling design guidelines can make a big difference in how smooth and affordable your low volume production runs.

Advanced Considerations for Low Volume CNC Milling

When working on low volume CNC milling projects, there are some advanced design factors worth keeping in mind to get the best balance between quality and cost.

Using 5 Axis Milling for Complex Geometries

5 axis CNC milling lets you create parts with complicated shapes and tight details that 3 or 4 axis machines can’t handle easily. But it’s more expensive. So, reserve 5 axis milling for parts where the complexity truly demands it or when a simpler design won’t meet performance needs. This keeps costs reasonable while unlocking advanced design possibilities.

Balancing Tight Tolerances with Production Costs

Tight tolerances increase machining time and cost—but they aren’t always necessary. Think carefully about which dimensions really need precision. Over-specifying can drive up the price without improving the part’s function. Work with your machinist or use DFM feedback tools to find the sweet spot between accuracy and affordability.

Leveraging HYCNC’s Quoting Platform for Instant DFM Feedback

One great way to optimize your design is to use HYCNC’s quoting platform. It provides instant design for manufacturability (DFM) feedback, helping you spot potential machining challenges early. This means you can adjust your design before production, saving time and cutting costs while ensuring your part meets quality requirements.

By considering these advanced tips, you can better navigate the trade-offs in low volume CNC milling and get parts that perform well without breaking the bank.

Common Mistakes to Avoid

When designing low volume CNC milled parts, it’s easy to make costly mistakes that don’t add value. Here are some common pitfalls to watch out for:

-

Over specifying tolerances

Tight tolerances can spike your machining costs, especially when they don’t improve the part’s performance. Only apply strict tolerances where they’re truly needed.

-

Designing features that need custom tools or multiple setups

Features requiring special tools or extra machine setups add time and expense. Stick to designs that can be machined efficiently with standard tooling.

-

Ignoring material-specific machining limits

Every material behaves differently in CNC milling. Overlooking these limits can cause tool wear, part damage, or added post-processing. Make sure your design matches the machining properties of the intended material.

Avoiding these mistakes helps keep costs in check and parts quality high when working with low volume CNC machining.

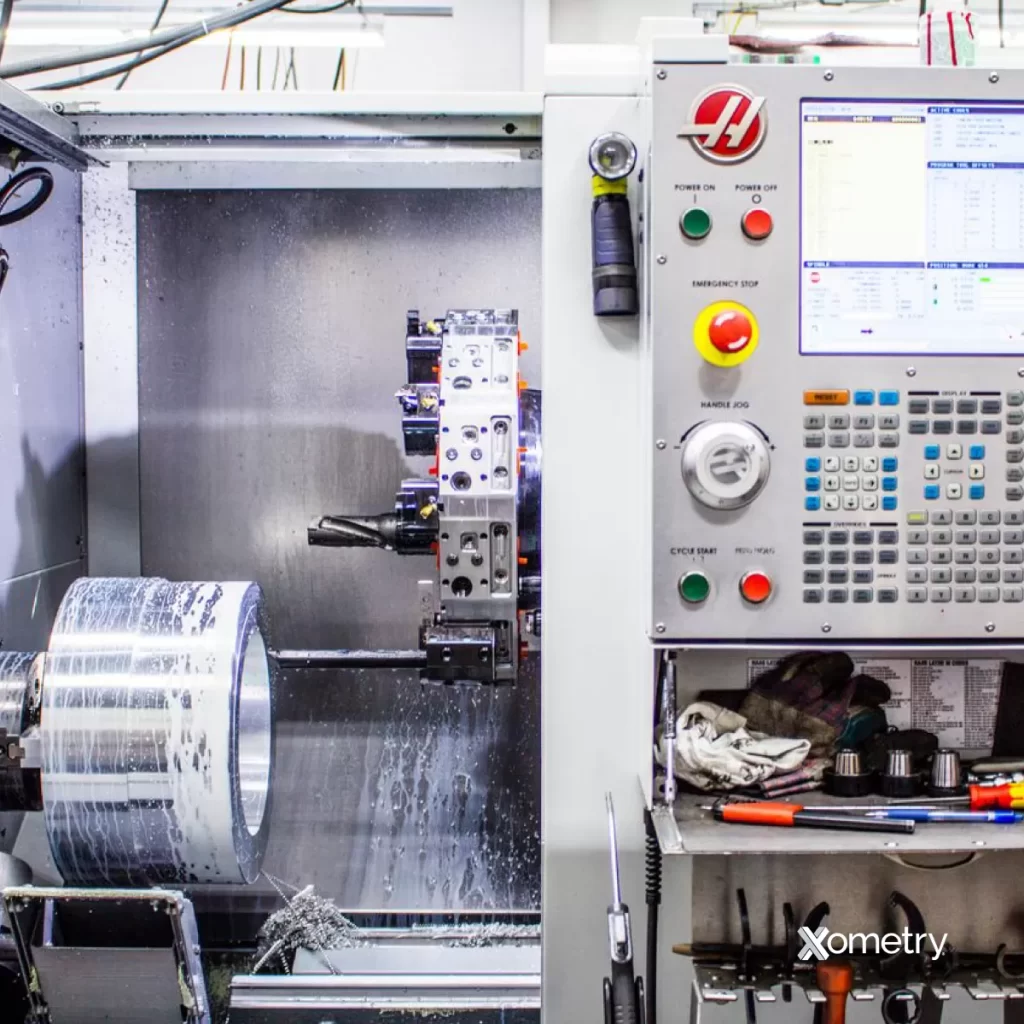

How HYCNC Supports Your Low Volume CNC Milling Projects

At HYCNC, we specialize in low volume CNC machining, focusing on rapid prototyping and small batch production. Whether you need 10 or 10,000 parts, we offer flexible solutions with a wide range of material options to suit your project’s needs.

Partnering with HYCNC means you get more than just machining — we provide design for manufacturability (DFM) analysis to help optimize your CNC part design. This approach cuts down costs and machining time while improving part performance.

Ready to get started? Upload your CAD file now for an instant quote and see how HYCNC can make your low volume CNC milling process smoother and more cost-effective.