Dimple Forming: Precision Metal Shaping You Can Trust

Dimple forming is a specialized technique in sheet metal fabrication that presses small indentations—called dimples—into metal surfaces. This process strengthens the material, improves rigidity, and reduces weight without compromising quality. At HYCNC, we deliver expert CNC dimple forming services tailored for industries where precision and durability matter most.

Serving sectors like aerospace, automotive, and heavy machinery, our advanced CNC metal processing ensures each dimple is formed with exact specifications. Whether you need custom CNC machining for metal surface texturing or high-precision sheet metal dimpling, we combine cutting-edge technology with deep expertise to meet your unique project demands.

Benefits & Industries We Serve

-

Aerospace dimple forming for lightweight, durable panels -

Automotive metal dimpling for enhanced strength and style -

Precision metal forming for custom fabrication projects -

Custom CNC machining services with high-precision and reliability

What is Dimple Forming? Process Explanation & Suitable Materials

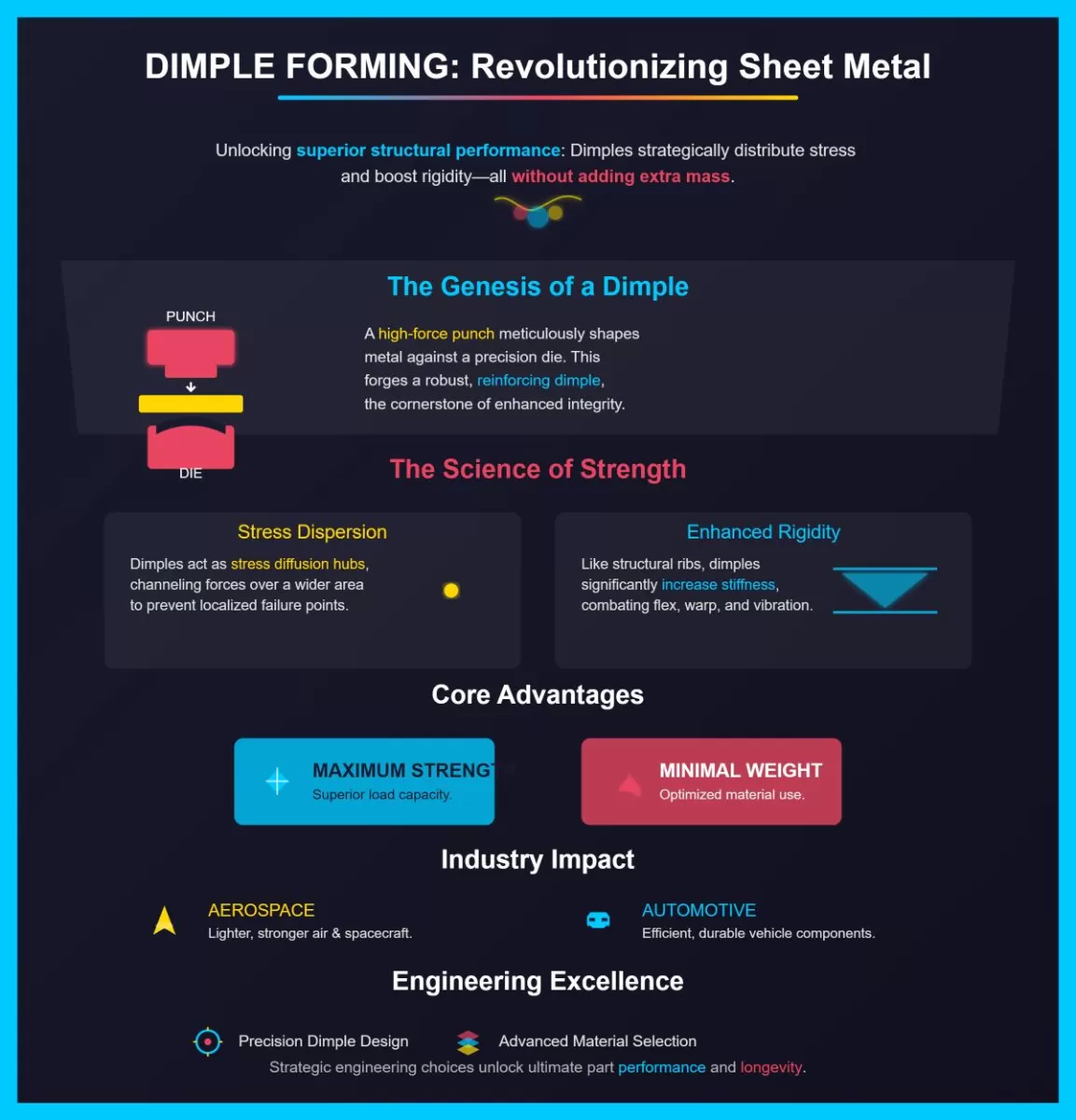

Dimple forming is a precise metal fabrication technique used to create small, rounded indentations—or dimples—on sheet metal surfaces. This process strengthens the metal by increasing rigidity without adding weight, making it ideal for aerospace, automotive, and other high-performance applications.

Typically performed with CNC dimple forming equipment, the process involves pressing a punch into the metal sheet to form an exact dimple shape. This precision metal forming method allows for consistent and repeatable results, improving joint strength and surface texture.

Start with materials suitable for dimpling, including aluminum, stainless steel, carbon steel, and other alloys commonly used in custom CNC machining.

High-precision CNC services punch dimples with exact depth and pattern, ensuring consistent strength and surface texturing.

Ensure all dimples meet design specs to enhance durability in aerospace dimple forming or automotive metal dimpling applications.

Dimple Forming Benefits with HYCNC

Discover how our precision dimple forming services deliver unmatched customization, fast turnaround, and cost-effective solutions for your metal fabrication needs.

-

Precision Customization: Tailored CNC dimple forming for aerospace, automotive, and sheet metal dimpling projects with exacting detail. -

Fast Turnaround: High-precision CNC services and custom machining keep your projects moving quickly without sacrificing quality. -

Cost-Effectiveness: Efficient CNC metal processing and metal surface texturing reduce waste and lower fabrication costs.

Dimple Forming Industries We Serve

We specialize in precision metal forming and CNC dimple forming across multiple industries in the United States. From automotive to aerospace and electronics, our custom CNC machining and metal fabrication services deliver quality you can trust.

Automotive Metal Dimpling

We handle high-volume sheet metal dimpling for car bodies, chassis parts, and surface texturing to improve strength and aesthetics.

Aerospace Dimple Forming

Precision CNC metal processing for aerospace components, ensuring structural integrity and compliance with strict tolerance standards.

Electronics

Custom CNC machining for metal enclosures and components, with precise dimpling to enhance heat dissipation and durability.

Why Choose HYCNC for Dimple Forming?

We’re your trusted partner for dimple forming with unmatched local expertise. Whether you need CNC dimple forming for aerospace precision or automotive metal dimpling, our certified equipment and skilled team deliver consistently reliable results.

How Our Dimple Forming Process Works

From your initial consultation to the final quality inspection, our dimple forming process is designed for precision and reliability. We combine advanced CNC machining and expert metal fabrication services to ensure every sheet metal dimple is crafted to spec.

We start by understanding your project requirements including material type, dimple pattern, and precision needs.

Our engineers program the CNC machines tailored for sheet metal dimpling and precision metal forming using custom tools and parameters.

We execute the dimple forming process on high-precision CNC equipment, ensuring consistent depth and shape across all parts.

Each part undergoes a thorough inspection to meet aerospace and automotive standards for metal surface texturing and dimensional accuracy.

We deliver your finished components on time and offer ongoing support to help integrate our quality CNC metal processing into your production flow.

Local Dimple Forming Services Near You

Looking for reliable dimple forming right in your backyard? Our CNC dimple forming services offer precision metal shaping with a local touch, tailored to meet the needs of businesses across the United States. Whether you need sheet metal dimpling for aerospace parts or automotive metal dimpling, we deliver consistent quality fast—saving you on shipping time and costs.

By choosing local metal fabrication services, you get:

Faster turnaround thanks to nearby production facilities

Personalized support from expert technicians who understand your regional industry demands

Accessible quality control allowing for on-site inspections and adjustments

Cost-effective CNC metal processing without compromises on precision or finish

Expertise in Precision Metal Forming

We specialize in high-precision CNC services ensuring every dimple is formed with perfect accuracy.

Quick Turnaround & Local Delivery

Avoid long waits and high freight fees with our efficient production close to your facility.

Custom CNC Machining Support

Tailored dimpling solutions fit your project’s exact specs with expert CNC metal processing.

Industry-Focused Service

Serving aerospace, automotive, and other local industries with metal surface texturing and sheet metal dimpling.