What is CNC Machining?

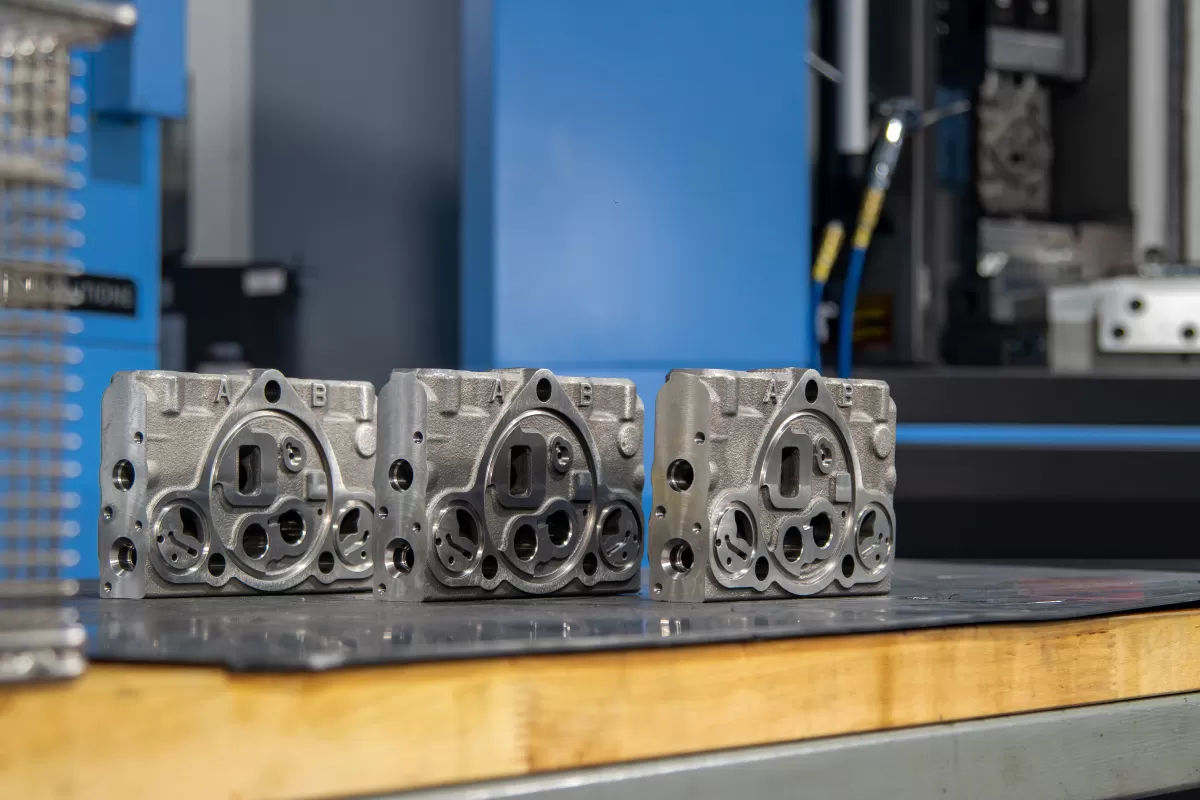

CNC machining is a computer-controlled manufacturing process that produces parts with unmatched precision and consistency. It uses automated machines to perform key operations like milling, turning, drilling, and finishing — all programmed to follow exact specifications.

The biggest benefits of CNC machining are:

-

Precision & Repeatability: Every custom CNC part is consistently accurate to tight tolerances. -

Versatile Processes: Milling, turning, drilling, and finishing all in one streamlined CNC machining service. -

Efficient Production: Ideal for one-off CNC prototyping or full-scale CNC manufacturing runs. -

Wide Material Support: Works with metals and plastics for versatile CNC metal fabrication and engineering.

Our CNC Machining Services

We deliver expert CNC machining across milling and turning processes to meet your project needs. Whether it’s

3-axis, 4-axis, or 5-axis CNC milling for complex geometries, or precise cylindrical parts with

CNC turning lathe services, we have you covered.

CNC Milling: 3-axis, 4-axis & 5-axis precision machining

CNC Turning: Lathe-based precision cylindrical parts

Materials: Aluminum, steel, titanium, plastics

Prototyping: From low volume runs to high volume production

Finishing: Anodizing, plating, powder coating for durability & style

Industries We Serve with CNC Machining

-

Aerospace -

Automotive -

Medical -

Electronics

Our precision CNC machining services specialize in delivering custom CNC parts that meet the demands of critical sectors. We manufacture aircraft components and medical implants with strict adherence to industry compliance standards, including NIMS certifications. Whether you need CNC milling services or CNC turning services, our CNC machine shop supports rapid prototyping and full-scale manufacturing to ensure your project’s success.

Our CNC Machining Process: Precision From Start to Finish

Step-by-step consultation, design review, machining, quality assurance, and delivery.

Benefits of Local CNC Machining in Your Area

Working with a local CNC machine shop means faster delivery, lower shipping costs, and tailored precision CNC machining that meets your region’s unique manufacturing needs.

CNC Machining FAQs: Materials, Timing & Quality

We work with a wide range of materials including:

- Aluminum and stainless steel

- Brass, copper, and titanium

- Engineering plastics (Delrin, Nylon, ABS)

- Specialty alloys and composites

Turnaround often depends on the project scope:

- Prototyping: 3-7 business days

- Small production runs: 7-14 business days

- Larger manufacturing orders: timelines customized per project

Yes! Whether you need custom CNC parts for prototyping or large-scale manufacturing, our CNC manufacturing solutions scale with your needs.

We accept the most common CAD and CAM file types including:

- STEP (.step, .stp)

- IGES (.iges, .igs)

- DXF and DWG

- SOLIDWORKS files (.sldprt, .sldasm)

- Other industry-standard formats

Every part undergoes strict quality inspections:

- Dimensional checks via CMM tools

- Material traceability and certification

- Process validation & monitoring

- Final visual and functional inspection

Get Started with CNC Machining Services

Ready to bring your project to life? Upload your design files, request a custom quote, or connect with our skilled team today. We make precision CNC machining accessible and straightforward for your custom CNC parts, CNC prototyping, and CNC manufacturing needs.

Phone

Call us for fast answers and personalized CNC metal fabrication advice.

Available: Mon-Fri, 8am–6pm EST

Send detailed requests for precision CNC machining services or custom CNC parts.

Accessibility

Our team is ready to assist all customers with accessibility needs, ensuring smooth CNC turning and milling service experiences.