Introduction to Water Jet Machining

Water jet machining is a non-traditional machining process that uses a powerful stream of high-pressure water — sometimes combined with abrasives — to cut through various materials with remarkable precision. Unlike conventional cutting methods, it does not rely on heat or mechanical force, making it ideal for applications where material integrity must be preserved.

The core components in this process include a high-pressure pump that pressurizes the water, an intensifier to maintain consistent pressure, a specialized nozzle that focuses the water jet, and an abrasive system when cutting tougher materials like metals or composites.

Since its evolution in the 1970s — from initial use in cleaning to today’s precision cutting services — water jet machining has become a go-to solution for industries needing clean, exact cuts without heat-affected zones. This includes everything from aerospace components to custom metal fabrication.

Why Choose Water Jet Machining

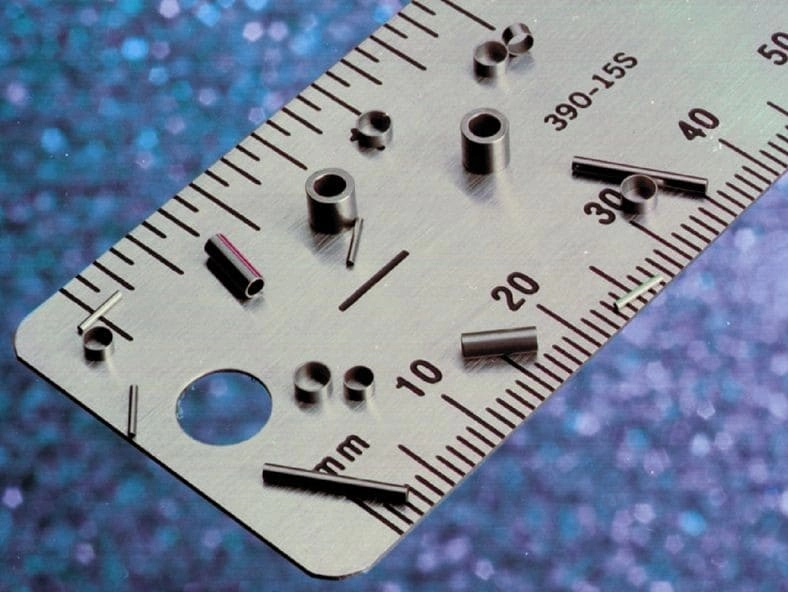

Water jet machining stands out for its ability to cut diverse materials—including metals, glass, and composites—with unmatched precision. Unlike laser, EDM, or plasma cutting, this non-thermal machining process preserves material integrity by avoiding heat-affected zones and thermal distortion. The thermoneutral nature of water jet cutting ensures parts hold tight tolerances of ±0.1 mm, ideal for critical applications.

For advanced manufacturing needs, water jet machining complements other CNC processes perfectly. Whether you need abrasive water jet machining for thicker materials or fast CNC water jet cutting, this technology is a top pick for precision cutting services across industries. Learn more about how water jet compares with other cutting techniques in our detailed guide on laser, plasma, and waterjet CNC cutting methods.

How Water Jet Machining Works

Water jet machining uses a high-pressure stream of water—pressurized up to 400 MPa—to cut and shape materials with unmatched precision. In abrasive water jet machining, the water mixes with abrasive particles that erode the material surface, creating clean cuts without heat damage.

We use pure water jets for softer materials like rubber or foam, providing a clean, non-thermal machining method that avoids warping. For metals and harder surfaces, abrasive water jet machining (AWJ) is ideal—combining water and abrasive media to cut through metal and composites effortlessly.

Key Parameters Affecting Performance

Water jet machining relies on a high-pressure stream of water—often mixed with abrasive particles—to cut materials with exceptional precision and no heat damage. The process is fully controllable through several key parameters that determine cutting efficiency and quality:

- Traverse Speed: Dictates how quickly the cutting head moves; affects surface smoothness and cutting time.

- Hydraulic Pressure: Higher pressure increases cutting power and can cut denser metals or thicker materials.

- Stand-Off Distance: The gap between the nozzle and material surface; impacts kerf width and accuracy.

- Abrasive Type & Flow Rate: Choosing the right abrasive and its flow ensures consistent material removal and finish quality.

These parameters together influence the material removal rate, surface roughness, and kerf width, making water jet machining a versatile, non-thermal machining option for metals, composites, and delicate materials. For deeper understanding of CNC precision processes, check out our precision machining services.

Applications of Water Jet Machining

Industries Served by HYCNC’s Water Jet Machining

At HYCNC, we deliver precise and efficient CNC water jet cutting tailored to diverse industries. Our abrasive water jet machining technology is perfect for cutting metal, composites, and sensitive materials without heat damage. Check out some of the key sectors we serve:

-

Aerospace: Titanium, composites, aluminum parts needing high precision and non-thermal machining.

-

Automotive: Intricate component and prototype designs that require custom water jet machining.

-

Construction: Cutting granite, marble, steel structural elements with high-pressure water cutting.

-

Biomedical: Precision implants and devices that benefit from non-thermal, contamination-free machining.

-

Food Processing: Contamination-free cutting to maintain hygiene and product integrity.

Why Choose HYCNC for Water Jet Machining

HYCNC’s Advanced Water Jet Technology

Our custom water jet machining services combine precision cutting services with eco-friendly machining techniques, offering unmatched accuracy without any thermal impact on your materials. Whether you’re looking for precision machining or non-thermal machining to retain material integrity, HYCNC’s water jet cutting technology stands out as a reliable choice. Experience cutting-edge CNC water jet cutting tailored for demanding applications and materials.

Real Case Studies

Precision cutting of CFRP/Ti6Al4V stacks for aerospace components—achieving tight tolerances with our advanced precision machining and non-thermal abrasive water jet machining that avoids heat-induced damage.

Granite cutting for architectural projects with smooth finishes using high-pressure water cutting that ensures clean edges and eliminates micro-cracking common with traditional methods.

Advantages and Limitations of Water Jet Machining

Water jet machining offers key benefits for a wide range of industries in the United States. As a non-thermal machining method, it avoids heat-related damage and reduces burrs, delivering smooth finishes on parts. It cuts through almost any material except diamond and carbide, making it super versatile. Plus, it’s an eco-friendly machining option, producing no hazardous gases and minimal waste.

No thermal stress, minimal burrs, smooth finishes

Cuts almost any material except diamond and carbide

Environmentally friendly: no hazardous gases or excessive waste

Get Started with HYCNC: Water Jet Machining Made Easy

Upload your design, specify your material, and receive a custom quote — fast and hassle-free.

Supporting local businesses with precision, eco-friendly water jet machining services — your trusted CNC service for high-pressure water cutting and non-thermal machining solutions.

FAQs: Frequently Asked Questions About Water Jet Machining

We handle a wide range of materials with our water jet machining, including metals like steel and aluminum, composites, stone, glass, and even delicate materials that require non-thermal machining to avoid heat damage.

Our CNC water jet cutting provides excellent precision, especially on thicker materials where laser cutting often struggles. It’s perfect for custom water jet machining projects demanding clean, accurate edges without thermal distortion.

Costs vary based on material type, thickness, and complexity. While abrasives add some expense, the eco-friendly machining process minimizes post-production cleanup, saving time and money on large or precision jobs.

We specialize in high-pressure water cutting for both large runs and intricate custom projects using advanced CNC water jet cutting systems, delivering consistent quality and reliability every time.

Water jet machining is a sustainable choice—there’s no hazardous fumes or heat-affected zones, and the processes largely use recycled water and minimal waste, reinforcing our commitment to eco-friendly machining.