Why CNC Machining is Essential for Medical Device Production

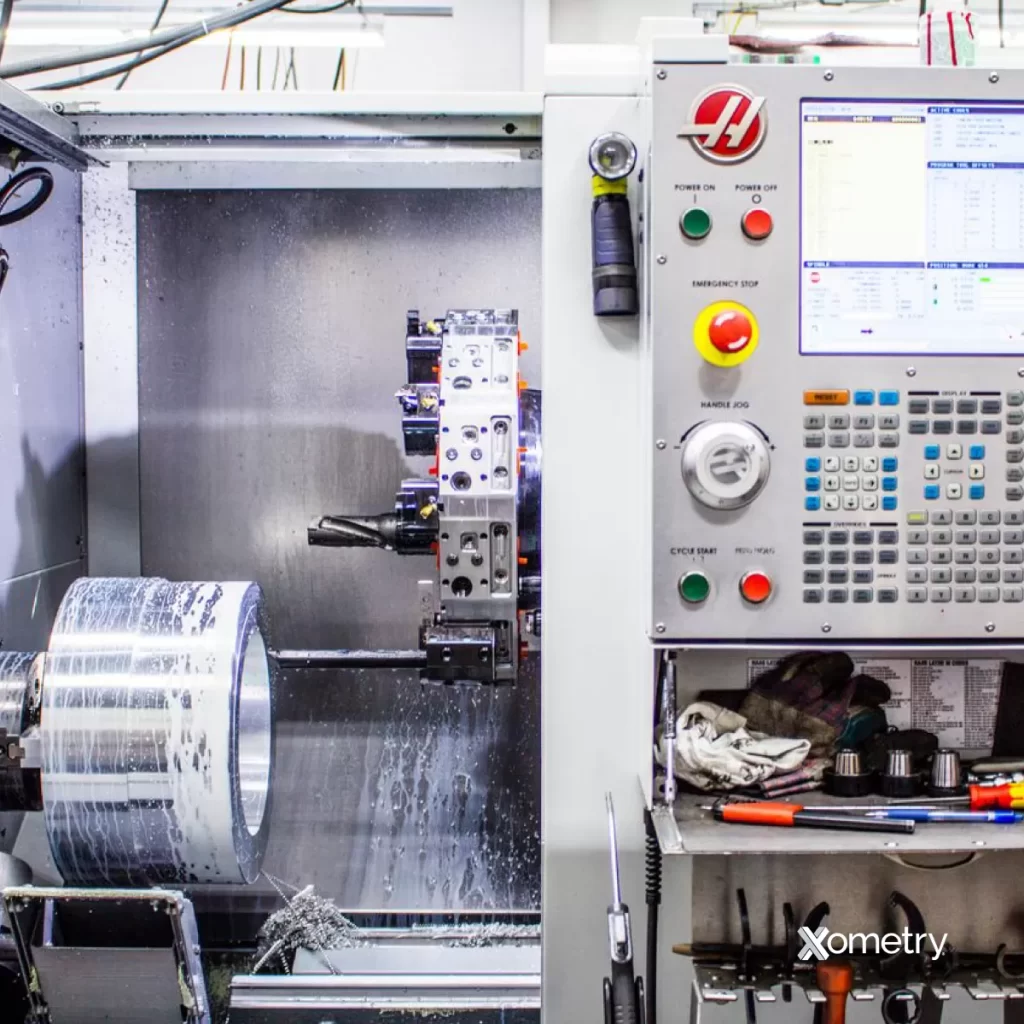

When it comes to medical device production, precision and reliability are non-negotiable. CNC machining plays a crucial role in meeting the high standards required in this industry. Here’s why CNC machine services are essential for producing safe, effective, and compliant medical devices.

Precision and Accuracy

Medical devices must be manufactured with micron-level precision to ensure safety and functionality. CNC machining offers:

- Consistent, repeatable accuracy across complex parts

- Tight tolerances that reduce the risk of device failures

- Superior surface finishes critical for patient safety

This level of precision supports everything from surgical instruments to intricate implant components.

Regulatory Compliance

Manufacturing medical devices means adhering to strict regulations like FDA standards and ISO 13485. CNC machining supports regulatory compliance by:

- Producing parts that meet documented quality standards

- Enabling traceability and validation through precise manufacturing records

- Using biocompatible materials machined under controlled conditions

Staying compliant ensures devices are safe for patient use and ready for market approval.

Complex Geometries

Medical devices often have complex shapes and fine details that traditional manufacturing can’t achieve efficiently. CNC machining excels at:

- Creating intricate internal and external features with 5-axis and Swiss CNC machining

- Producing detailed prototypes to validate designs faster

- Machining tiny micro-devices with precision

This versatility supports innovation in diagnostic equipment, implants, and prosthetics.

Material Versatility

Medical device production demands a wide range of biocompatible and durable materials such as titanium, stainless steel, and medical-grade plastics. CNC machining offers:

- Expert handling of diverse materials without compromising integrity

- Precision machining of hard-to-machine materials like titanium used in implants

- Custom solutions tailored for material properties and application needs

This versatility ensures the final product meets both performance and patient safety requirements.

By combining unmatched precision, strict compliance, and versatile capabilities, CNC machining is the backbone of modern medical device production. It enables manufacturers to deliver safe, reliable, and effective products that meet the evolving demands of healthcare.

HYCNC’s CNC Machining Services for Medical Devices

At HYCNC, we specialize in precision CNC machining for medical devices, delivering reliable solutions tailored to your unique needs. Our services cover everything from custom parts to full-scale production runs, ensuring you get high-quality results every time.

Core Capabilities

We bring advanced 5-axis CNC machining for implants, Swiss CNC machining for medical components, and titanium CNC machining for medical devices right to your project. Our equipment handles complex shapes and tight tolerances with ease, making sure your parts fit perfectly and perform flawlessly.

Customization

Every medical device project is different, so we focus on custom CNC machining for prosthetics, surgical instruments, and micro-devices that meet the exact specs you require. Whether it’s biocompatible CNC machining or working with specialized materials, we adapt our process to fit your goals.

Prototyping

Developing a new device? We offer fast, accurate medical device prototyping that lets you test and refine your design before moving to production. Our prototyping service helps you save time and money by catching issues early with precise CNC milling and turning.

Quality Assurance

We know regulatory compliance is critical in medical device production. That’s why HYCNC strictly follows ISO 13485 CNC machining standards and maintains rigorous quality checks throughout the process. You can trust us for consistent, traceable results that meet industry requirements.

With HYCNC’s CNC machining services, you get a partner focused on precision, reliability, and flexible manufacturing to support your medical device projects from start to finish.

Applications of CNC Machine Services in Medical Device Production

CNC machining plays a key role in making a wide range of medical devices that demand precision and reliability. Here’s where it shines the most:

Surgical Instruments

CNC milling for surgical instruments ensures sharp, precise edges and durable surfaces. Whether it’s scalpels, forceps, or clamps, the ability to produce intricate shapes with tight tolerances makes CNC machining ideal for tools surgeons depend on every day.

Implants and Prosthetics

When it comes to implants and prosthetics, biocompatible CNC machining is crucial. Using advanced methods like 5-axis CNC machining for implants and Swiss CNC machining for small components, manufacturers can produce customized titanium and stainless steel parts that fit perfectly and perform reliably inside the human body.

Diagnostic Equipment

From MRI components to precise housings for diagnostic tools, CNC machining provides consistent quality and complex geometries needed in diagnostic devices. The high accuracy supports sensitive equipment that requires stable performance and long service life.

Micro-Devices

Medical micro-devices, including tiny sensors and minimally invasive tool parts, benefit from advanced CNC machining services that offer exceptional precision on very small scales. This capability supports cutting-edge medical technology used in various treatments and monitoring devices.

By applying CNC machining expertly across these areas, manufacturers meet the tough demands of the medical field with high-quality, reliable components.

Benefits of Choosing HYCNC for Medical CNC Machine Services in Medical Device Production

When it comes to medical CNC machining services, choosing the right partner can make all the difference. At HYCNC, we bring several key advantages that cater specifically to the needs of medical device manufacturers in the U.S.

Unmatched Precision and Accuracy

Medical device production demands precision CNC machining for medical devices that meet extremely tight tolerances. We use advanced 5-axis CNC milling and Swiss CNC machining techniques to deliver parts with consistent accuracy. Whether you’re producing implants, surgical instruments, or micro-devices, our precision ensures they function safely and reliably.

Fast Turnaround Times

In this industry, speed matters. Our streamlined processes and skilled team enable quick prototyping and production runs without compromising on quality. This means you get your custom CNC machining for prosthetics or diagnostic equipment on time to keep your projects moving.

Extensive Material Expertise

Medical devices often require biocompatible CNC machining for materials like titanium, stainless steel, and medical-grade plastics. Our team is experienced in working with a wide range of materials, including titanium CNC machining for medical applications, ensuring every component meets strict medical standards.

Regulatory Compliance You Can Trust

We understand the importance of ISO 13485 CNC machining standards in medical device production. HYCNC follows rigorous quality control and documentation protocols to help you maintain regulatory compliance. Our processes support audits and certifications, so your medical components are production-ready for regulatory review.

Cost Efficiency Without Compromise

By combining cutting-edge technology with efficient workflows, we deliver high-quality CNC machining at competitive prices. Whether it’s a single prototype or low-volume production, our services help you control costs while meeting all quality and compliance requirements.

Local and Global Reach

With a strong presence in the United States, HYCNC offers the benefit of local support and fast logistics, combined with a global manufacturing network to handle scale. This makes us an ideal partner whether you need small batches or large-volume runs of medical device parts.

At HYCNC, we’re committed to delivering reliable, precise, and compliant CNC machining solutions tailored for the medical device industry. For more details on our machining capabilities, you can check out our precision machining services and learn how we help medical device makers meet their production goals efficiently.

How HYCNC Stands Out in Medical CNC Machine Services in Medical Device Production

When it comes to medical CNC machining services, HYCNC sets itself apart through a blend of deep experience, cutting-edge technology, and a customer-first approach. Here’s what makes us a top choice for precision CNC machining for medical devices in the U.S. market.

Extensive Experience in Medical CNC Machining

With years of specialized work in biocompatible CNC machining and ISO 13485 CNC machining standards, HYCNC understands the strict regulatory and quality demands of medical device production. Our team knows how critical precision and compliance are, especially when working on implants, prosthetics, and surgical instruments.

Advanced Technology for Complex Medical Components

We use advanced equipment like 5-axis CNC machining for implants and Swiss CNC machining for medical components to handle even the most intricate designs. This technology allows for tight tolerances and flawless finishes essential for devices that need to meet safety and functional regulations. Whether it’s titanium CNC machining for medical devices or custom parts, our machines deliver consistent quality.

Customer-Centric Approach Tailored to Your Needs

At HYCNC, you’re not just another order number. We focus on custom CNC machining for prosthetics and other medical devices by offering personalized support at every step—from prototyping to production. Our goal is to make the process smooth and transparent, with clear communication and on-time delivery.

Real Results Backed by a Case Study

One of our recent projects involved CNC milling for surgical instruments requiring extremely tight tolerances and biocompatible materials. Using our advanced milling and turning capabilities, we helped a U.S.-based medical device company reduce their production time by 30% while improving overall quality. This case highlights how HYCNC’s expertise and technology combine to deliver measurable benefits.

In , HYCNC stands out because of:

- Decades of experience in medical CNC machining

- Leading-edge CNC milling and turning technologies

- Strong focus on customer partnerships

- Proven track record with complex medical device projects

Choosing HYCNC means choosing a partner dedicated to helping you meet the high standards and tight deadlines your medical device production demands.

How to Get Started with HYCNC for Medical Device CNC Machining

Starting your medical device project with HYCNC is straightforward and designed to get your product from concept to market efficiently. Whether you need precision CNC machining for medical devices, prototyping, or full production, we’re here to help every step of the way.

Consultation Process

- Initial Contact: Reach out to us via phone or email to discuss your project requirements.

- Detailed Assessment: We review your design files and specifications to understand the scope and challenges.

- Feasibility and Quote: Our team provides feedback on manufacturability and a competitive quote tailored to your needs.

- Material and Process Selection: We help you choose the best materials—like titanium or biocompatible alloys—and CNC services such as 5-axis machining or Swiss CNC machining.

Prototyping to Production

- Rapid Prototyping: We offer fast-turn prototyping to validate designs before scaling up.

- Iterative Feedback: Get hands-on with prototypes, suggest tweaks, and finalize your medical device design.

- Full-Scale Production: Once approved, we move to production with strict adherence to ISO 13485 CNC machining standards and regulatory compliance.

- Quality Assurance: Every part undergoes thorough inspections, ensuring the precision and reliability you expect for medical applications.

Contact Information and Local Focus

- Reach Us Locally: We serve medical device manufacturers across the United States, offering local support with a global reach.

- How to Connect: Visit our website or call us to schedule a consultation or request a quote.

- Ongoing Support: We aren’t just a service provider—we’re your partner, ready to assist with design changes, volume adjustments, or material advice as your product evolves.

By choosing HYCNC, you tap into expert medical CNC machining services that prioritize your timeline, budget, and regulatory needs—making your path to market smoother and faster.

For more details on our capabilities, check out our medical device services page and explore our range of precision machining services.

FAQs About CNC Machine Services in Medical Device Production

What makes CNC machining essential for medical device production

CNC machining offers unmatched precision, essential for meeting strict medical standards. It ensures accurate, repeatable results, handles complex geometries, and works with biocompatible materials like titanium—all critical for safe, reliable medical devices.

Can HYCNC handle custom CNC machining for prosthetics and implants

Yes, HYCNC specializes in custom CNC machining for prosthetics and implants, including 5-axis CNC machining for complex designs. We work closely with clients to tailor parts that fit exact specifications and regulatory requirements.

How does HYCNC ensure quality and regulatory compliance

We adhere to ISO 13485 CNC machining standards and maintain rigorous quality checks throughout the process. Our quality assurance protocols ensure every component meets FDA and other applicable regulations for medical devices.

What materials can HYCNC machine for medical devices

HYCNC machines a wide variety of materials, including titanium CNC machining for medical, stainless steel, plastics, and biocompatible alloys. This versatility supports diverse medical applications like surgical instruments and diagnostic equipment.

Can I get prototyping services before full production

Absolutely. We offer medical device prototyping to test designs quickly and efficiently, helping you move smoothly from concept to volume production without surprises.

How fast can HYCNC deliver CNC machining services for medical devices

Our streamlined workflow and advanced equipment allow for a fast turnaround without sacrificing quality. We prioritize time-sensitive projects common in the medical field.

Does HYCNC provide guidance during the project

Yes, our team takes a customer-centric approach and partners with you from consultation through prototyping to final production, ensuring your needs are met at every step.

Where can I learn more about specific CNC machining techniques used in medical device manufacturing

You can explore our detailed service pages like CNC machining and check out our blog posts to understand more about precision machining processes and innovations in medical device production.

If you have more questions about medical CNC machining services or want to get started, reach out to us anytime. We’re here to ensure your medical device manufacturing needs are met with precision and reliability.