Why Choose Plastics for CNC Machining?

Plastics offer unmatched versatility and precision when it comes to CNC plastic machining. Unlike metals, plastics enable faster cutting speeds, lower tooling costs, and exceptional design flexibility. They’re lighter, resist corrosion, and provide excellent electrical insulation — making plastics an ideal choice for custom plastic parts in many industries. Plus, with the right plastic material selection, you can tailor properties like strength, heat resistance, and chemical durability to fit your specific needs.

Common Plastic Materials for CNC

We work with diverse plastics like ABS, Delrin (Acetal), Nylon, Polycarbonate, and UHMW. Each offers unique plastic properties—from high impact resistance to chemical stability—delivering precision plastic fabrication that meets strict industry standards.

Benefits of Plastic vs Metal in Machining

Plastics machine faster and cleaner, reduce wear on cutting tools, and allow complex geometries at lower cost. They’re also excellent for sustainable plastic machining efforts, as many types are recyclable and create less scrap compared to metals.

HYCNC’s CNC Plastic Machining Services

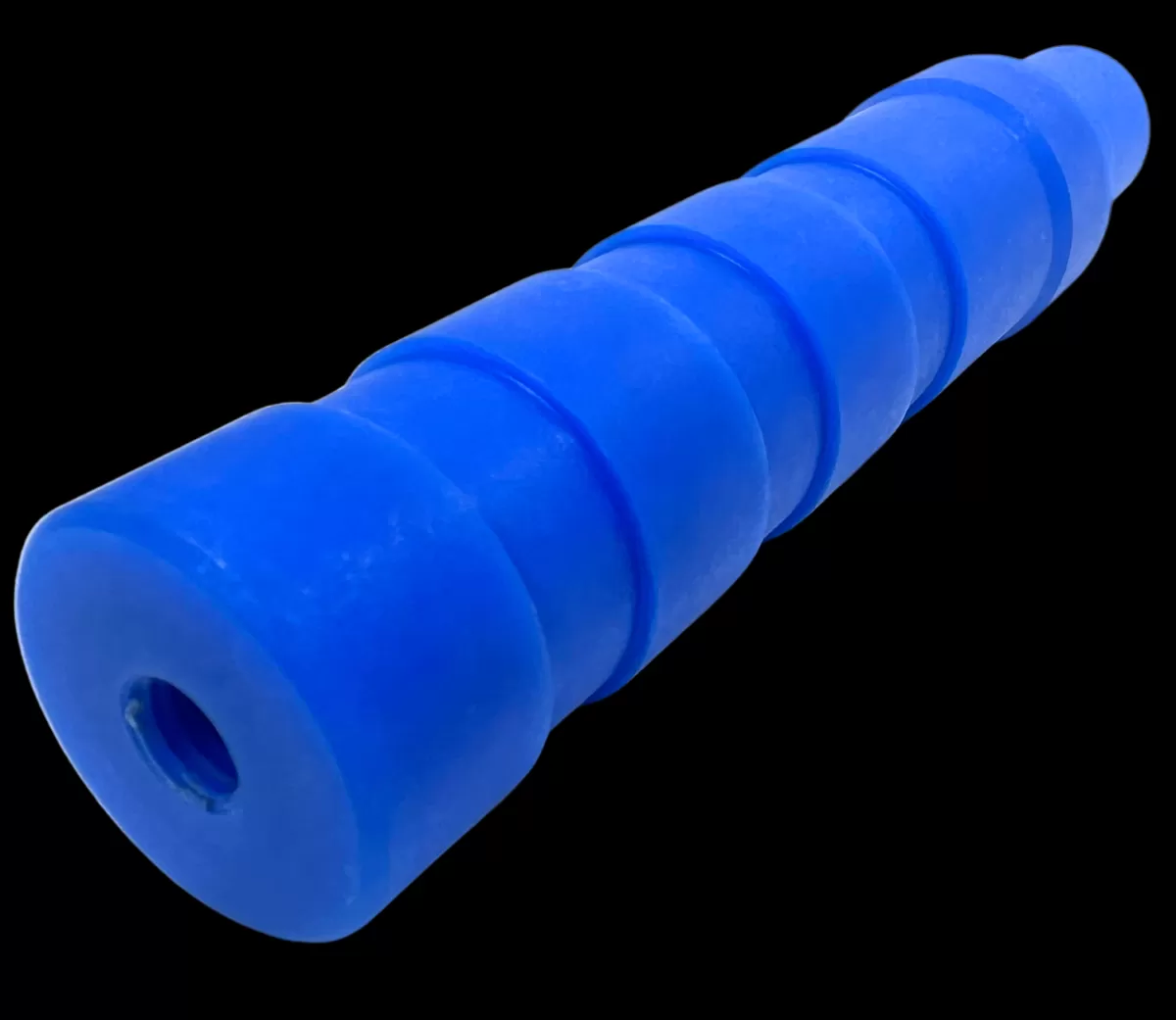

At HYCNC, we specialize in precision CNC plastic machining to deliver custom plastic parts that fit your needs—whether it’s prototyping or large-scale production. Our expertise covers a wide range of plastic materials, ensuring the right plastic material selection for your project. Every part we produce meets strict quality assurance standards and tight tolerances for reliable performance.

-

Custom Plastic Components Crafted Precisely -

Prototyping and Large-Scale Production Capability -

Strict Quality Assurance & Tolerance Control -

Expertise in Precision Plastic Fabrication

Choosing the Right Plastic for Your Project

Selecting the best plastic material is key to quality CNC plastic machining. Each project calls for specific plastic properties—like, flexibility, or chemical resistance—to perform reliably and last. I help you navigate the types of plastics available and match the perfect custom plastic parts to your application.

Popular Plastics for CNC Machining

Acrylic (PMMA)

Delrin (Acetalspan>

Nylon (PA)

Polycarbonate (PC)

HDPE

Industry-Specific Material Recommendations

| Industry | Recommended Plastics | Why It Works |

|---|---|---|

| Medical | Polycarbonate, Delrin, Acrylic | Biocompatibility, sterilization tolerance, and clarity |

| Automotive | Nylon, HDPE, Polycarbonate | Durability, heat resistance, and impact strength |

| Electronics | Acrylic, Polycarbonate, Delrin | Electrical insulation, precision machining, and thermal stability |

| Food & Beverage | HDPE, Polycarbonate | FDA compliance, chemical resistance, and food safety |

| Industrial | Nylon, Delrin, HDPE | Wear and abrasion resistance, chemical stability |

Sustainability in Plastic Machining

Embracing sustainability in CNC plastic machining means more than just precision—it’s about reducing waste, selecting eco-friendly plastics, and improving recyclability in every custom plastic part we create. We focus on sustainable plastic machining practices that maximize material efficiency and minimize environmental impact.

We optimize tool paths and material selection to cut down on scrap, ensuring that plastic material is used efficiently without compromising precision.

We incorporate eco-friendly plastics where possible—biodegradable alternatives that reduce long-term waste and support environmentally conscious product cycles.

Choosing materials with renewable content and high recyclability ensures that parts we machine today won’t become tomorrow’s landfill problem.

Why Choose HYCNC for Plastic Machining

Our Process: From Design to Delivery

At HYCNC, we specialize in precise CNC plastic machining tailored for your custom plastic parts. Our process ensures seamless collaboration from concept through production:

-

Design Consultation: We advise on plastic material selection matching your product’s needs and sustainability goals. -

Precision CNC Fabrication: Using advanced plastic CNC services, we achieve tight tolerances with consistent quality. -

Quality Inspection & Testing: Every part undergoes thorough checks to ensure functional and aesthetic excellence. -

Fast, Reliable Delivery: We prioritize prompt shipping to keep your project on track without compromising quality.

Client Success Stories

FAQs About CNC Plastic Machining

Common Questions About Plastic Machining

What types of plastics can you machine with CNC?

How do I select the right plastic material for my custom parts?

What precision can I expect from your CNC plastic services?

How do you support sustainable plastic machining?

How does HYCNC support my CNC plastic machining project?

Contact HYCNC for Your Plastics Machining Needs

We specialize in precision plastic fabrication and CNC plastic machining to deliver custom plastic parts made with the best plastic material selection. Whether you need sustainable plastic machining or eco-friendly plastics, our plastic CNC services ensure quality and reliability for your project.