Introduction to G90 Steel and HYCNC’s Expertise

G90 steel is galvanized steel coated with a zinc layer of 0.90 oz/ft², offering superior corrosion resistance and durability. Widely used in construction, automotive, and manufacturing industries, its reliability makes it a go-to material for projects demanding strength and longevity. At HYCNC, we specialize in precision CNC machining of G90 steel, crafting high-quality parts that meet your exact specifications. Looking for expert CNC service to handle your G90 steel needs? We deliver tailored components that combine robust material properties with advanced machining precision.

G90 Steel Properties and Galvanized Steel Specifications

G90 steel is a type of galvanized steel coated with zinc at a thickness of 0.90 oz/ft² (approximately 275 g/m²). This coating provides a robust layer of corrosion protection, making G90 steel a favorite in harsh environments. The galvanization process involves bonding zinc to mild steel, creating a protective barrier that prevents rust and extends the steel’s service life.

Key G90 Steel Properties

-

Corrosion Resistance: The thick zinc coating offers superior protection against rust, ideal for outdoor and humid conditions. -

Durability: Resistant to dents and scratches, G90 maintains its integrity longer than lower-grade coatings. -

Formability and Weldability: Easily shaped and welded, making it a good fit for diverse manufacturing processes, including hot rolled steel applications.

G90 Steel Specifications and Standards

G90 steel meets the ASTM A653 standard for coated steel sheets. The zinc coating thickness is typically between 2.3 to 2.5 mils (0.058-0.064 mm), providing a solid protective layer. It outperforms lower coatings like G60 and G40 in corrosion resistance and lifespan.

| Grade | Zinc Coating (oz/ft²) | Thickness (mils) | Corrosion Resistance |

|---|---|---|---|

| G40 | 0.40 | ~1.0 | Basic protection |

| G60 | 0.60 | ~1.5 | Moderate protection |

| G90 | 0.90 | ~2.3-2.5 | Superior protection |

Whether you’re choosing materials for construction, CNC machining G90 steel parts, or other precision applications, understanding these specifications ensures you pick the right steel for the job. For related steel materials that offer excellent machinability, consider our cold rolled mild steel options.

Applications of G90 Steel in Various Industries

G90 steel is a versatile material that serves a wide range of industries thanks to its exceptional corrosion resistance and durable galvanized coating. You’ll find G90 steel commonly used for roofing and siding in construction, where it protects structures from harsh weather. In the automotive industry, it’s trusted for manufacturing automotive parts that require strength and longevity. HVAC systems extensively use G90 steel for ducts due to its ability to resist corrosion over long periods.

Specifically, G90 steel’s application in construction is valued for reliable, corrosion-resistant roofing and structural components. At HYCNC, our advanced CNC machining boosts the precision cutting and forming of G90 steel, ensuring the parts meet exact specifications required by demanding industries. This precision enables faster assembly and higher quality in everything from structural frameworks to HVAC ducts.

-

Construction: Roofing, siding, corrosion-resistant structural steel -

Automotive Parts: Durable, corrosion-resistant stamped components -

HVAC Systems: Ductwork and air handling units -

Structural Components: Precision-formed parts with enhanced durability

Why Choose G90 Steel for Your CNC Machining Projects

When it comes to CNC machining G90 steel, the benefits are clear. G90 steel’s superior corrosion resistance, thanks to its galvanized coating thickness, keeps parts durable and reliable—even in challenging environments. Its cost-effectiveness and versatility make it an ideal choice across construction and precision component applications.

90 steel’s ease of forming and consistent quality lets us at HYCNC deliver precision G90 steel parts with tight tolerances and smooth finishes every time. We leverage advanced CNC technology to handle G90 steel efficiently, ensuring your projects meet exact specifications without compromise.

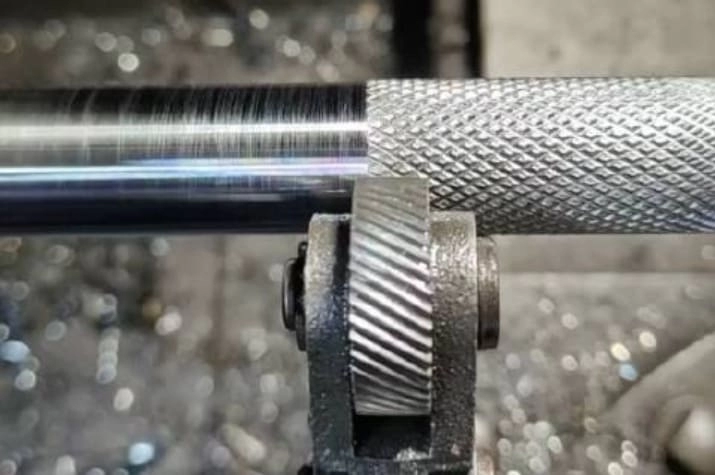

HYCNC’s CNC Machining Services for G90 Steel

At HYCNC, we pride ourselves on being your trusted partner for precision G90 steel machining. Our state-of-the-art CNC equipment handles every stage of working with G90 steel — from cutting and bending to forming and finishing — all with the quality control you expect. Whether you need parts for automotive components or specialized construction materials, we deliver unmatched precision and durability.

Supporting local manufacturers across the United States, we ensure faster deliveries and more personalized service. Our proven track record includes multiple successful projects where our expertise in HYCNC G90 steel machining helped bring complex designs to life smoothly and efficiently.

Advanced CNC Equipment for unmatched precision and tight tolerances

Full Service Processing including cutting, bending, forming, and finishing G90 steel parts

Proven Track Record with successful automotive and construction component projects

Local Support & Fast Delivery serving clients across the U.S. with responsive service

Strict Quality Control ensuring every precision G90 steel part meets specifications

How HYCNC Ensures Quality and Precision in G90 Steel Machining

At HYCNC, we understand that machining G90 steel demands precision and strict quality control. That’s why every project follows a stringent quality assurance process, ensuring your parts meet or exceed industry standards.

-

Adherence to ASTM standards for galvanized steel G90 quality -

Comprehensive dimensional inspections and coating thickness verification -

Certified team experienced in precision CNC processing of G90 steel -

State-of-the-art CNC technology optimized for tight tolerances and repeatability

Our commitment is proven by client success stories showing consistent on-time delivery of high-quality galvanized steel parts, enhancing corrosion resistance and structural performance in their projects.

Explore how our expertise with mild steel machining can elevate your next order: Precision Hot Rolled Steel Services and Cold Rolled Steel Solutions.

Get Started with HYCNC for Custom G90 Steel Machining

Ready to bring your project to life with precision G90 steel parts? Request a personalized G90 steel machining quote from HYCNC today. We specialize in fast turnaround and competitive pricing to support your custom manufacturing needs. Whether you’re looking for hot-rolled steel solutions or specific G90 steel coatings, we’ve got you covered.