Composites and CNC Machining: Precision That Mattersh2>

Composite materials, like fiber reinforced polymers including carbon fiber and glass fiber, are revolutionizing industries by offering unmatched strength-to-weight ratios. At the core of high-performance sectors—such as aerospace and automotive—precision composite machining is essential to unlock their full potential. That’s where tailored CNC machining composites solutions come in. With the right approach, we can carefully shape these advanced materials without compromising integrity or performance.

What Are Composite Materials?

- Fiber reinforced polymers combining strength & lightness

- Carbon fiber’s superior rigidity and stiffness

- Glass fiber’s affordability and corrosion resistance

- Designed for specialized performance in key industries

Why Precision CNC Machining?

- Ensures tight tolerances critical for aerospace composites

- Enables complex shapes and lightweight automotive composite parts

- Reduces waste by precisely cutting composite sheets

- Maintains material properties during carbon fiber machining

At HYCNC, we specialize in precision composite machining. Our tailored CNC services combine industry knowledge with cutting-edge equipment to meet the exacting demands of composite manufacturing. Whether it’s carbon fiber machining or fiberglass CNC processing, we deliver quality that high-performance industries trust.

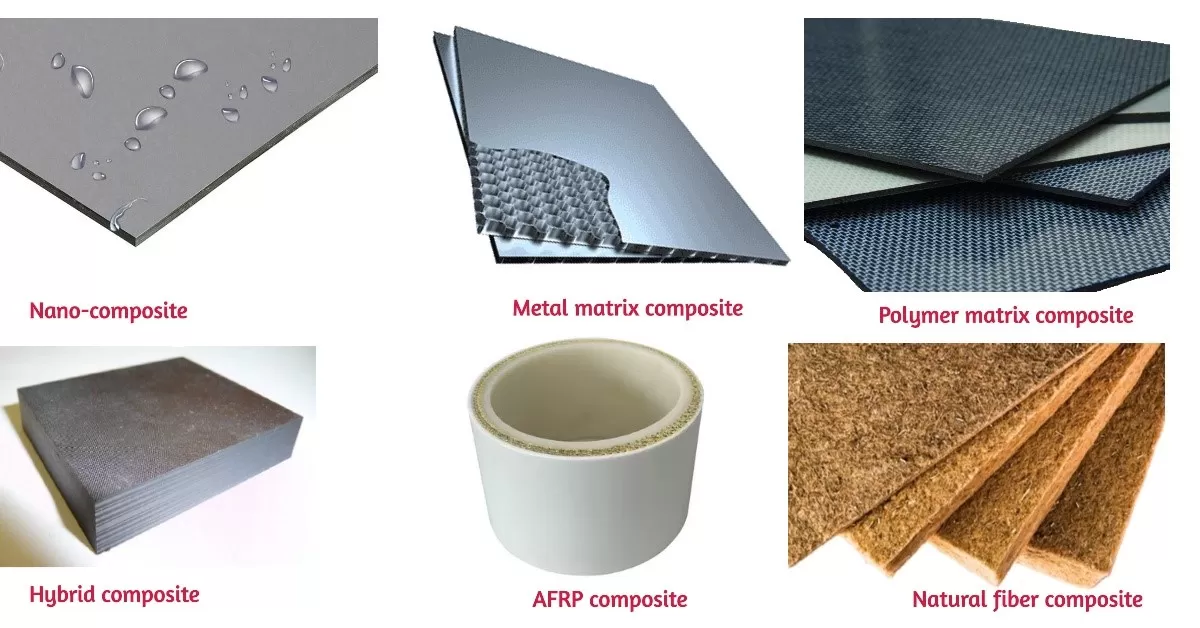

What Are Composite Materials?

Composite materials combine two or more distinct components—a matrix and a reinforcement—to create a product stronger than its parts alone. The matrix binds and protects, while the reinforcement boosts strength and stiffness.

- Carbon Fiber: Lightweight, exceptionally high strength and stiffness.

- Fiberglass: Cost-effective, good corrosion resistance.

- Kevlar: High impact resistance, excellent durability.

- Key Properties: Lightweight, high strength, corrosion resistance, durability.

- Matrix Types: Thermoset and thermoplastic polymers.

- Reinforcement: Fibers or particles embedded in the matrix.

- Applications: Aerospace composites, automotive composite parts, construction, renewable energy solutions.

- Industry Benefits: Reduced weight for better fuel efficiency, enhanced durability.

- Manufacturing: Modern composite manufacturing and precision CNC machining composites improve performance and reliability.

Benefits of CNC Machining for Composites

Unlock precise, efficient, and customizable composite machining for your toughest projects.

Precision for complex structures: CNC machining delivers highly accurate cuts and detailing, essential for complicated aerospace composites and automotive composite parts.

Versatile on composite types: Whether it’s carbon fiber machining (CFRP) or fiberglass CNC processing (GFRP), the process handles diverse composite materials with ease.

Less waste, more efficiency: Our CNC service ensures optimal material use, reducing waste and increasing your manufacturing efficiency and turnaround time.

Tailored for industries: Meet exact aerospace tolerances or drive automotive lightweighting with customized composite CNC services built for your needs.

HYCNC’s Composite CNC Machining Services

At HYCNC, we specialize in CNC machining composites with precision and speed. Our advanced 5-axis CNC machines handle milling, cutting, drilling, and finishing of a wide range of composite materials — from carbon fiber to fiberglass. We bring cutting-edge technology to every project for flawless results.

Comprehensive CNC Capabilities

-

Precision milling & cutting -

Multi-axis drilling & finishing -

Fine surface treatments for composites

Industries We Serve

-

Aerospace composites & parts -

Automotive composite parts -

Marine & renewable energy composites

Quality Assurance & Testing

-

Certified precision standards -

Rigorous composite material testing -

Track record of successful carbon fiber aerospace parts

Why Choose HYCNC for Composite Machining?

At HYCNC, we specialize in complex composite materials like carbon fiber and fiberglass, delivering precise, reliable results tailored to your needs. Whether it’s aerospace composites or automotive composite parts, our expert CNC machining composite services offer fast turnaround with competitive pricing.

-

Expertise in Complex Materials

Years of skilled experience machining high-performance carbon fiber and fiberglass. -

Fast Turnaround & Competitive Pricing

We balance speed with quality, ensuring efficient delivery without compromising precision. -

Customized Solutions

Every project is unique. We tailor composite CNC services specifically to your specifications. -

Commitment to Sustainability

We minimize waste through efficient composite manufacturing practices for a greener footprint. -

Proven Customer Success

Read customer testimonials and success stories that highlight our dedication and quality.

Applications of Composites in Key Industries

Composite materials play a vital role across major U.S. industries by enhancing performance and durability:

-

Aerospace Lightweight Components: Improving fuel efficiency with durable, lightweight parts. -

Automotive Structural Parts: Key materials in electric vehicles for strength and weight reduction. -

Renewable Energy: Wind turbine blades and solar panel frames built to withstand the elements. -

Construction: Durable, corrosion-resistant structures that last longer in tough environments. -

Marine: Composite hulls and decking providing strength and weight benefits for boats.

Whether it’s aerospace composites or automotive composite parts, mastering composite manufacturing and precision composite machining ensures reliable and optimized results for every project.

How HYCNC Ensures Quality in Composite Machining

At HYCNC, precision and reliability drive our composite CNC services. We go beyond standard manufacturing by applying advanced non-destructive testing (NDT) inspections throughout every stage of composite machining. This proactive approach catches microscopic defects early, ensuring your aerospace composites, automotive composite parts, and fiberglass CNC processing meet the highest quality demands.

-

Advanced Inspection – Non-destructive testing to verify composite material properties and structural integrity. -

Industry Compliance – Fully aligned with ISO certifications and aerospace-quality manufacturing standards. -

Expert Team – Skilled specialists who understand composite properties and unique machining challenges.

Our commitment ensures every cut, from carbon fiber machining to fiberglass CNC processing, meets exacting standards—delivering flawless composite parts you can trust.

Get Started with HYCNC’s Composite Machining Services

We specialize in precision composite machining, handling everything from carbon fiber machining to fiberglass CNC processing with ease. Upload your designs, get fast quotes, and start production quickly—our process is simple and customer-focused.

Upload Designs

Submit your CAD files or composite part specs for an accurate assessment.

Receive Quotes

Get fast, transparent pricing tailored to your composite manufacturing needs.

Start Production

We handle the rest—from CNC machining composites to quality control—for reliable results.

FAQs About Composites and CNC Machining

Advantages of Composites Over Traditional Materials

-

Lighter weight with high strength-to-weight ratio -

Superior resistance to corrosion and chemicals -

Customizable composite material properties tailored to needs -

Enhanced performance in aerospace and automotive composite parts

CNC Machining Process for Composites

CNC machining composites requires precision and care due to material sensitivity. Our CNC service uses:

-

Specialized tooling designed for carbon fiber and fiberglass CNC processing -

High-speed spindles and dust extraction for clean cuts -

Precision composite machining for tight tolerances and smooth finishes

Types of Composites We Can Process

-

Carbon fiber reinforced polymers (CFRP) -

Fiberglass composites for lightweight strength -

Hybrid composites combining multiple materials -

Thermoset and thermoplastic composites

Project Timelines for Composite Machining

We understand tight deadlines. Typical composite CNC machining timelines include:

-

Initial consultation and materials sourcing: 1-3 days -

CNC machining and quality checks: 3-7 days depending on complexity -

Finishing and delivery preparation: 1-2 days

We offer flexibility to match your project schedule.

Industries We Serve

-

Aerospace composites for high-performance applications -

Automotive composite parts to reduce weight and increase durability -

Marine and sporting goods industries -

Industrial and electronics components