What Are 3D Printed Motorcycle Parts

3D printed motorcycle parts are components made using additive manufacturing, a process that builds objects layer by layer from digital designs. Instead of traditional machining or molding, 3D printing lets you create complex parts directly from CAD files with precision and speed. This technology is transforming how motorcycle parts are made, giving riders and builders more options for customization and performance.

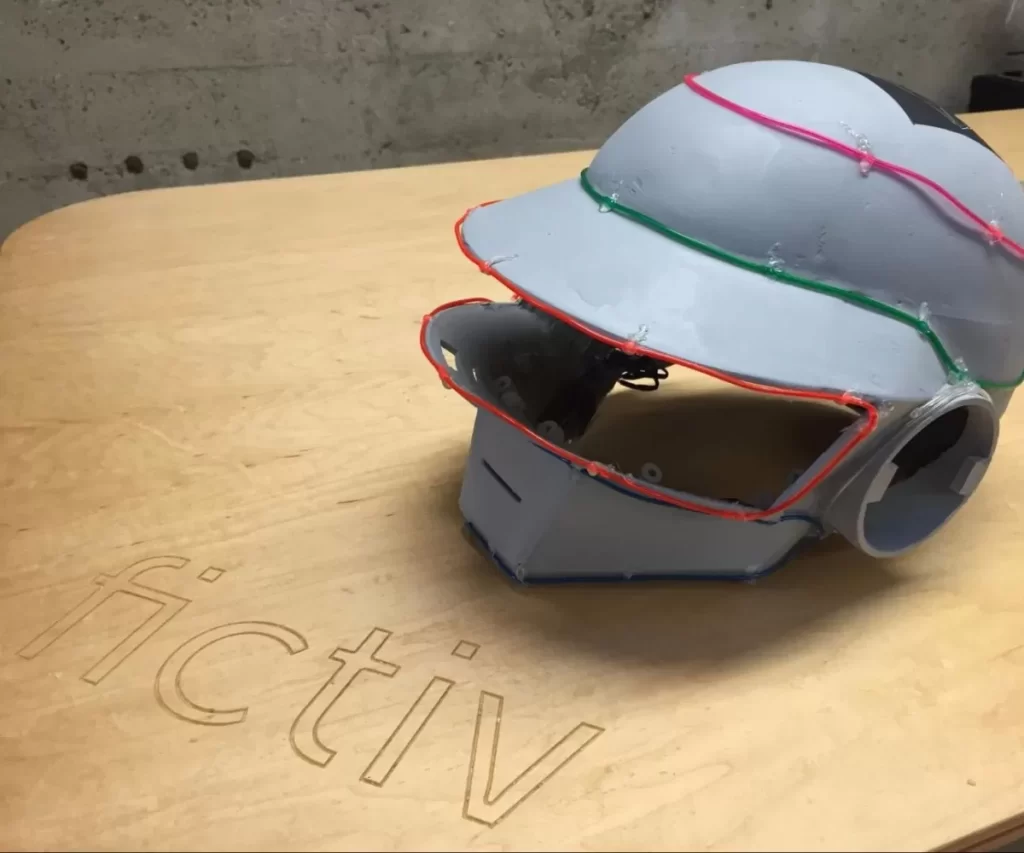

Common 3D printed parts for motorcycles include shift levers, linkages, dash housings, airbox joints, and a variety of aesthetic covers. These parts range from functional components that must withstand stress and heat to decorative elements that personalize the bike’s look.

Materials used in 3D printing motorcycle parts vary based on the application. Popular choices include:

- Nylon: strong, flexible, and resistant to wear and heat

- ABS: durable, impact-resistant, and heat-tolerant

- PET-G: tough, chemically resistant, and easy to print

- Carbon fiber reinforced PLA: lightweight yet very stiff and strong

Each material offers a balance of durability, heat resistance, and finish quality, making them suitable for different motorcycle parts.

The 3D printing process starts with designing a part in CAD software. After the design is finalized, it’s sliced into layers and sent to the printer. The printer then builds the part layer by layer, carefully following the file’s instructions. Post-printing, parts often undergo finishing steps like sanding, painting, or annealing to improve their surface smoothness and strength.

This blend of design freedom, material options, and finishing techniques makes 3D printed motorcycle parts a versatile and innovative solution for riders and manufacturers alike.

Benefits of 3D Printing for Motorcycle Parts

3D printing offers a bunch of advantages for motorcycle parts, especially if you’re looking to speed up development and save costs. Here’s why it stands out:

-

Rapid Prototyping

You can go from design to a real part in days instead of weeks. This cuts development time drastically, letting you test fit, function, and style fast.

-

Cost Efficiency

For low-volume runs or prototypes, 3D printing is way cheaper than traditional machining or molding. You avoid expensive tooling and setup fees, which is perfect for custom or small batch projects.

-

Unlimited Customization

Additive manufacturing lets you create complex shapes and geometries that traditional methods can’t handle. This opens the door to better performance parts and eye-catching designs tailored just for your bike.

-

Less Waste

Unlike subtractive processes that cut away material, 3D printing only uses what’s needed. This means less scrap and a more eco-friendly approach to making parts.

-

Weight Reduction

Printing parts with lightweight materials helps lower the overall weight of your motorcycle. This is a big win for electric bikes and racers who want every advantage in performance.

-

Surface Finishing Options

Once printed, parts can be sanded, painted, or otherwise finished to match your desired look and feel. This ensures your custom parts not only perform well but also look great on the road.

These benefits make 3D printing a smart choice for riders, builders, and manufacturers looking to innovate without breaking the bank.

Challenges and Limitations

3D printed motorcycle parts come with some challenges you should know about. One big issue is scalability. Printing takes time—especially for larger parts or bigger batches—and material options can be limited compared to traditional manufacturing. This can slow down mass production or make it harder to get certain properties.

Durability is another concern. While materials like Nylon, ABS, or carbon-fiber-reinforced PLA are strong, they might not always handle extreme stress or heat like metal parts do. So, for high-stress components, 3D printed parts need careful design and material choice.

Plus, getting started with 3D printing means an upfront investment in printers and materials, which can be expensive. But this is where service providers like HYCNC help. They use advanced printers and pick the right materials to meet durability and performance needs, making it easier for riders, shops, and manufacturers to get high-quality custom parts without breaking the bank.

Applications of 3D Printed Motorcycle Parts

3D printed motorcycle parts open up a world of possibilities for riders and builders alike. They’re perfect for custom builds that demand unique, one-of-a-kind designs you just can’t find off the shelf. Whether you want a bold new look or specific features tailored to your bike, 3D printing makes it possible to bring your ideas to life.

For manufacturers and hobbyists, rapid prototyping is a game-changer. You can quickly print and test parts, checking fit and function in real-world conditions before committing to final production. This speeds up development and cuts costs.

If you’re restoring a vintage or rare motorcycle, 3D printing is a lifesaver for replacement parts that are no longer made or are super expensive. Custom parts can be recreated with great accuracy, helping keep your classic bike running and looking great.

On the performance side, 3D printing offers lightweight components like shift levers and linkages that improve agility and speed, especially valuable for racers and electric motorcycles where every ounce counts.

Finally, it’s great for aesthetic upgrades—dash housings, covers, and assorted accessories that help personalize your bike’s style. These parts can be customized in shape, color, and finish, letting you make a statement on the road.

Why Choose HYCNC for 3D Printed Motorcycle Parts

At HYCNC, we combine deep expertise in both CNC machining and 3D printing to deliver precision and quality you can trust. Our use of advanced technology, including the Raise3D Pro3 HS printers, lets us create highly detailed, durable motorcycle parts tailored to your exact needs.

We offer a wide range of material options like Nylon, ABS, and carbon fiber composites, so you get parts that meet your performance and durability requirements. Whether you’re an individual enthusiast, a bike shop, or a manufacturer, we customize solutions that fit your project perfectly.

Our fast turnaround times help reduce lead times, which means you get your prototypes or production parts quicker. Plus, we provide cost-effective services especially suited for low-volume and custom 3D printed motorcycle parts, making it easier and more affordable to bring your ideas to life.

How to Get Started with HYCNC

Getting your custom 3D printed motorcycle parts with HYCNC is simple and straightforward. Here’s how it works:

- Free consultation: We start by chatting about your design needs, goals, and what you want to achieve with your parts.

- Submit or create your design: You can send us your CAD files or work with our team to develop the 3D model if you need help.

- Material selection: Based on where and how your part will be used, we help you pick the best material—whether it’s Nylon, ABS, carbon fiber PLA, or others—to make sure it’s durable and reliable.

- Rapid prototyping and testing: We quickly print prototypes so you can test fit, function, and feel before final production.

- Production and delivery: Once approved, we move to fast, precise production for single pieces or batch runs to fit your timeline.

Ready to bring your 3D printed motorcycle parts to life? Contact HYCNC for a quote or consultation today, and let’s get your custom project rolling.