What is 5-Axis Milling for Highly Complex Parts

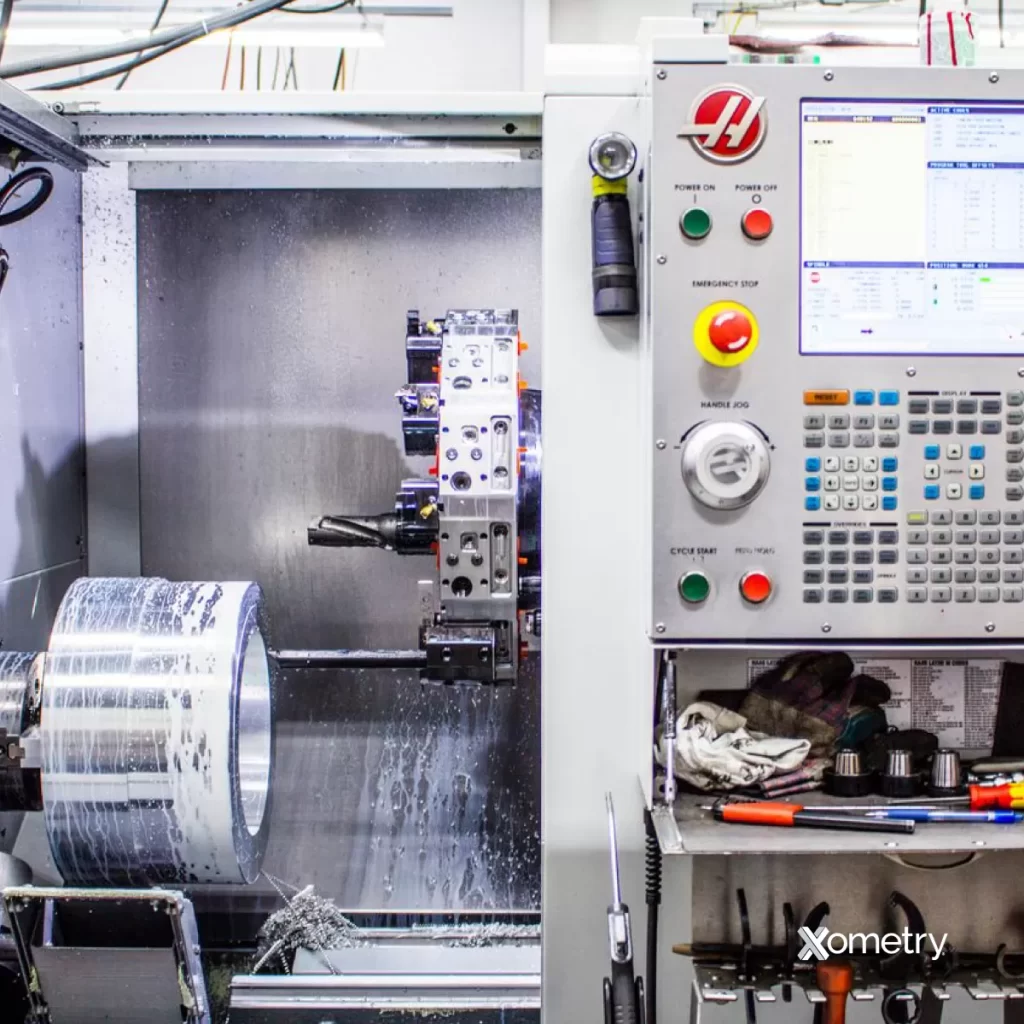

Definition of 5-Axis Milling

5-axis milling is an advanced CNC machining process that moves a cutting tool across five different axes simultaneously. Unlike traditional 3-axis or 4-axis CNC machines, 5-axis machines can rotate on multiple planes, allowing them to create complex geometry parts with exceptional accuracy. This capability makes 5-axis milling ideal for producing parts with intricate shapes, tight tolerances, and detailed surface finishes.

Types of 5-Axis Milling

There are mainly two types of 5-axis milling machines used in precision CNC machining:

- Head-Table Type: Both the cutting head and the worktable move; the head can tilt and rotate while the table provides rotational movement.

- Head-Head Type: Both axes are controlled via the tool head, which tilts and rotates independently of the stationary worktable.

Each type offers unique advantages depending on the part complexity and production requirements.

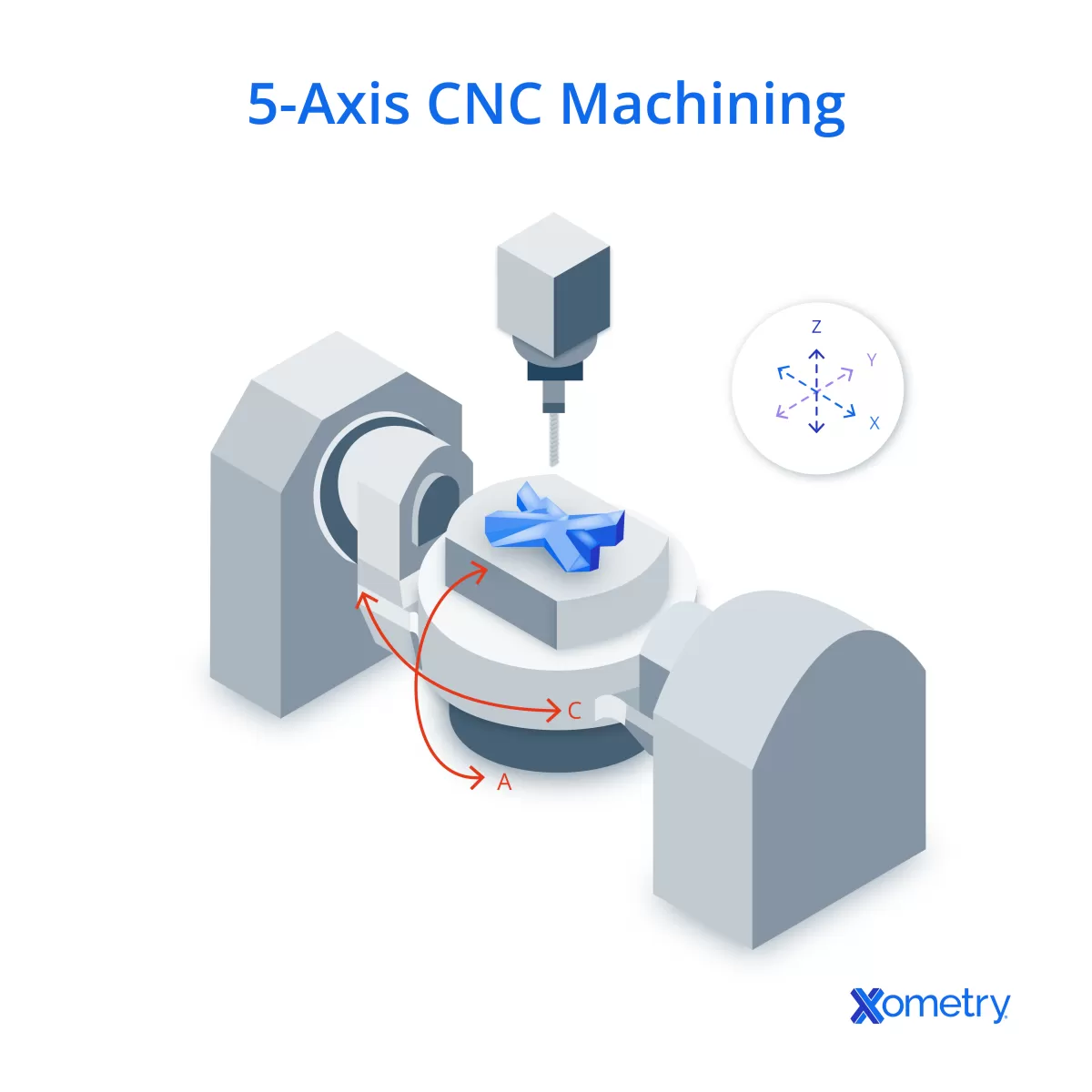

Key Components of 5-Axis CNC Services

To deliver top-quality simultaneous 5-axis milling, several critical components come into play:

- Rotary Axes: Additional axes (beyond X, Y, Z) that rotate the workpiece or the cutting tool for multi-directional access.

- High-Precision Spindle: Enables stable, high-speed machining for various materials from aluminum to titanium.

- Advanced CAD/CAM Software: Essential for toolpath generation and simulation, ensuring efficient and accurate machining of highly complex parts.

- Control System: Coordinates the movement of all five axes smoothly, critical for maintaining precision during cutting.

- Rigid Machine Frame: Minimizes vibrations and ensures stability, enhancing the high-tolerance machining quality.

Understanding these components highlights why 5-axis milling is a game-changer in manufacturing complex geometry parts across industries.

Why Choose 5 Axis Milling for Highly Complex Parts

When it comes to precision CNC machining for complex geometry parts, 5 axis milling stands out for several reasons. Here’s why this method is ideal for highly intricate components:

Superior Precision

5 axis CNC services allow cutting tools to move along five different axes simultaneously. This flexibility means tighter tolerances and more accurate results, which is crucial for industries like aerospace and medical device manufacturing where high-tolerance machining is non-negotiable.

Single Setup Efficiency

With 5 axis milling, you can machine most parts in a single setup, reducing the need to reposition the workpiece multiple times. This saves time, minimizes errors, and improves repeatability, making the whole process more efficient compared to traditional 3-axis or 4-axis machining.

Ability to Handle Complex Geometries

Parts with intricate shapes and deep contours are no problem for 5 axis CNC milling. The machine can approach the part from multiple angles, enabling it to create complex curves, undercuts, and challenging surfaces that would be tough or impossible with lower-axis machines.

Enhanced Surface Finish

Since the cutting tool maintains an optimal angle to the surface throughout the process, the result is smoother finishes and less post-machining work. This is especially important when working with materials requiring tight surface standards.

Versatility Across Materials

5 axis milling works well with a wide range of materials—from tough aerospace alloys to delicate medical-grade titanium. This versatility supports various applications where precision and material properties are critical, giving you confidence regardless of your project’s demands.

Applications of 5 Axis Milling for Highly Complex Parts in Key Industries

5 axis milling plays a crucial role in producing complex geometry parts across several major industries. Its ability to handle intricate designs with precision makes it a go-to choice where exactness and reliability matter.

Aerospace Industry

In aerospace machining, 5 axis milling is essential for manufacturing components like turbine blades, engine mounts, and structural parts. These parts require high-tolerance machining and complex shapes that only simultaneous 5 axis milling can achieve efficiently. The technology helps reduce weight while maintaining strength, improving fuel efficiency and safety.

Automotive Industry

Automotive prototyping and production increasingly depend on 5 axis CNC services for parts such as engine components, transmission parts, and custom fixtures. The capability to machine complex geometry parts in a single setup speeds up development cycles, reduces errors, and results in better performance parts.

Medical Industry

Medical device manufacturing uses 5 axis milling for implants, surgical instruments, and prosthetics. The precision CNC machining enables tight tolerances and superior surface finishes necessary for biocompatibility and patient safety.

Energy Sector

In the energy field, 5 axis milling supports the production of components for turbines, oil and gas equipment, and power generation hardware. These parts often demand intricate designs and durable materials that benefit from the versatility of 5 axis machining.

Case Study

At HYCNC, we recently completed a project for a leading aerospace provider producing a complex turbine blade using 5 axis milling. The part’s intricate curves and tight tolerances were flawlessly achieved in a single setup, cutting production time by 30% compared to traditional methods. This example highlights how our 5 axis CNC services deliver both quality and efficiency for highly complex parts in demanding industries.

For more tips on achieving a good surface finish on machined parts, check out our blog on surface finishing.

Benefits of Partnering with HYCNC for 5 Axis Milling of Highly Complex Parts

When you choose HYCNC for 5 axis milling for highly complex parts, you get more than just machining—you get a partner committed to precision and efficiency. Here’s why working with us makes a difference:

Advanced Technology for Precision CNC Machining

At HYCNC, we use the latest 5-axis CNC services paired with cutting-edge CAD/CAM software. This combination allows us to handle even the most complex geometry parts with ease, ensuring superior precision and consistency across every job.

Skilled Workforce for Expert Handling

Our team of experienced machinists and engineers specializes in precision CNC machining. They know how to optimize toolpaths, manage material behavior, and deliver tight tolerances, guaranteeing that your complex parts come out exactly as designed.

Quality Assurance You Can Trust

Quality is non-negotiable. We implement rigorous inspection processes at every stage of production. From high-tolerance machining checks to detailed surface finish assessments, we make sure your parts meet or exceed industry standards before they leave our facility.

Fast Turnaround Times to Meet Your Deadlines

We understand that speed matters. Our streamlined workflow, combined with automation and single-setup machining techniques, lets us deliver your projects faster without sacrificing quality. For info on delivery times, see our How Long Does It Take to Deliver CNC Machined Parts guide.

Custom Solutions Tailored to Your Needs

Each project is unique, and so are our solutions. Whether you need prototype parts in aerospace machining or custom components for medical device manufacturing, we design our process to fit your specifications and material requirements. This flexibility ensures optimal performance for your application.

Partnering with HYCNC means tapping into reliable, efficient, and precise 5-axis milling services that empower your business to handle even the most challenging parts with confidence.

How HYCNC Ensures Success in 5-Axis Milling for Highly Complex Parts

At HYCNC, delivering precision and quality in 5-axis milling for complex geometry parts is our top priority. We focus on several critical areas to guarantee success for each project.

Design for Manufacturability

Before machining starts, we work closely with you to optimize part designs specifically for 5-axis milling. This early collaboration reduces production challenges and ensures smoother workflow. By applying design principles tailored to CNC machining, we help:

- Minimize unnecessary features that raise costs

- Simplify complex geometries without compromising functionality

- Ensure your CAD models are ready for smooth programming and machining

This step means fewer revisions, faster turnaround, and higher quality outputs.

Toolpath Optimization

Using advanced CAD/CAM software, we create precise and efficient toolpaths that exploit the full potential of 5-axis CNC services. Proper toolpath planning ensures:

- Reduced machine time through effective cutting angles

- Better surface finish by avoiding overcuts or tool marks

- Enhanced tool life and lower tooling costs

Our skilled programmers adjust strategies based on part complexity and material, enabling simultaneous 5-axis milling that handles even the toughest designs with accuracy.

Material Expertise

Different materials require specific approaches. Our team’s material expertise covers metals, plastics, and composites common in aerospace machining, automotive prototyping, and medical device manufacturing. We understand how various materials react to tooling and speeds, ensuring:

- Optimal cutting parameters for high-tolerance machining

- Minimization of thermal distortion or stress in sensitive components

- Consistent finishes regardless of material choice

This knowledge helps us machine complex parts efficiently while maintaining tight tolerances.

Automation

To boost precision and reduce errors, HYCNC leverages automation where possible. This includes:

- Automated tool changing and setup adjustments

- Machine monitoring for real-time quality control

- Integration of CAD/CAM data with machine controls for seamless transitions

Automation streamlines the 5-axis milling process and accelerates production without sacrificing quality.

By focusing on design for manufacturability, toolpath optimization, material expertise, and automation, HYCNC ensures your complex parts are delivered on time, within budget, and up to the highest standards. For more on precision CNC machining and part design, check our guide to precision CNC milling components.

Comparing 5-Axis Milling to 3-Axis and 4-Axis for Complex Parts

Limitations of 3-Axis Milling

3-axis milling is great for simpler shapes, but it hits its limits quickly when dealing with complex geometry parts or intricate details. It moves the tool in three directions—X, Y, and Z—but can’t easily reach angled surfaces or deep pockets without multiple setups. This often means:

- Multiple setups, increasing time and chances for error

- Limited ability to handle curved or angled surfaces smoothly

- Less efficient for high-tolerance machining where precision is critical

4-Axis vs 5-Axis Milling

4-axis adds rotation around one axis, which improves flexibility over 3-axis, but it’s still not enough for some complex parts. 5-axis milling lets the tool move in five different directions simultaneously, allowing for:

- Single-setup machining of complex geometries

- Easier access to hard-to-reach areas without repositioning the part

- Better surface finish and precision on high-tolerance parts

In essence, 5-axis CNC services handle more complex shapes faster and more accurately than 4-axis, which still requires some compromises or extra setups.

Cost vs Value of 5-Axis Milling

It’s true that 5-axis milling has a higher upfront cost compared to 3 and 4-axis machining. However, the value outweighs the cost because:

- Fewer setups reduce labor and error, saving money in the long run

- Faster production speeds mean shorter lead times

- Ability to handle complex, high-precision parts without outsourcing

- Improved surface finish reduces the need for extra post-processing

When you choose 5-axis milling for complex parts, you’re investing in a process that delivers better quality, efficiency, and reliability—perfect for industries like aerospace, medical, and automotive where precision is non-negotiable.

Getting Started with HYCNC’s 5-Axis Milling Services for Highly Complex Parts

Request a Quote for Precision 5-Axis CNC Machining

Ready to tackle your complex geometry parts with expert 5-axis CNC services? Simply reach out to us with your project details. We’ll review your designs and offer a transparent, competitive quote tailored to your specific needs. Our goal is to provide clear pricing quickly so you can plan your production schedule with confidence.

Consultation Process for Complex Geometry Parts

We don’t just provide milling; we partner with you from start to finish. During the consultation, we:

- Analyze your CAD files and confirm manufacturability

- Discuss materials, tolerances, and surface finish requirements

- Suggest design tweaks based on design for manufacturability best practices

- Plan optimized toolpaths to ensure quality and efficiency

This process ensures your aerospace machining, automotive prototyping, or medical device manufacturing runs smoothly with minimal revisions.

Contact Information for Your CNC Project Needs

Have questions or want to jumpstart your project? Contact the HYCNC team directly by phone or email. We’re here to assist with technical advice, guide you through the quoting process, and schedule production. Reach us at:

- Phone: (Insert local US contact number)

- Email: [email protected]

- Or visit our website to submit your request online

Start your project with HYCNC’s advanced technology and skilled workforce supporting your 5-axis milling needs today. For more insight into how advanced CNC machining enhances part quality, check out our blog on why 5-axis CNC is ideal for complex parts.

Frequently Asked Questions About 5 Axis Milling for Highly Complex Parts

What materials can HYCNC machine with 5-axis milling

We work with a wide range of materials, from aluminum and titanium to stainless steel, Inconel, and various plastics. Our 5-axis CNC services handle both soft and hard materials, making it easy to produce complex geometry parts across industries like aerospace, automotive, and medical device manufacturing.

How does 5-axis milling reduce production costs

5-axis milling cuts costs by enabling single-setup machining, which means fewer setups and less time on the machine. This lowers labor and overhead while improving precision to reduce waste. Also, simultaneous 5-axis milling reduces tool changes and improves cycle times—leading to faster, more cost-effective production.

What industries benefit most from HYCNC’s 5-axis services

Our 5-axis CNC machining is especially valuable in:

- Aerospace, for machined parts with tight tolerances and complex features

- Automotive prototyping where precision and speed are crucial

- Medical device manufacturing needing highly detailed, high-tolerance components

- Energy sector parts requiring durable, complex designs

The versatility of 5-axis milling supports a broad range of applications in these fields.

How fast can HYCNC deliver complex parts

Turnaround depends on part complexity and production volume, but we pride ourselves on fast delivery without sacrificing quality. Many complex parts can be delivered in a matter of days to a few weeks. Our streamlined processes, skilled workforce, and automation maximize efficiency to meet tight deadlines.

What tolerances can HYCNC achieve with 5-axis milling

We consistently hold tight tolerances down to ±0.0005 inches (±0.0127 mm) depending on the material and design. This precision is critical for high-tolerance machining projects in aerospace and medical device manufacturing, ensuring your parts fit and function perfectly the first time.

If you have more questions or need a custom solution, feel free to reach out. We’re here to help you bring your complex parts to life with reliable, precision 5-axis CNC machining.