What Is Rapid CNC Machining

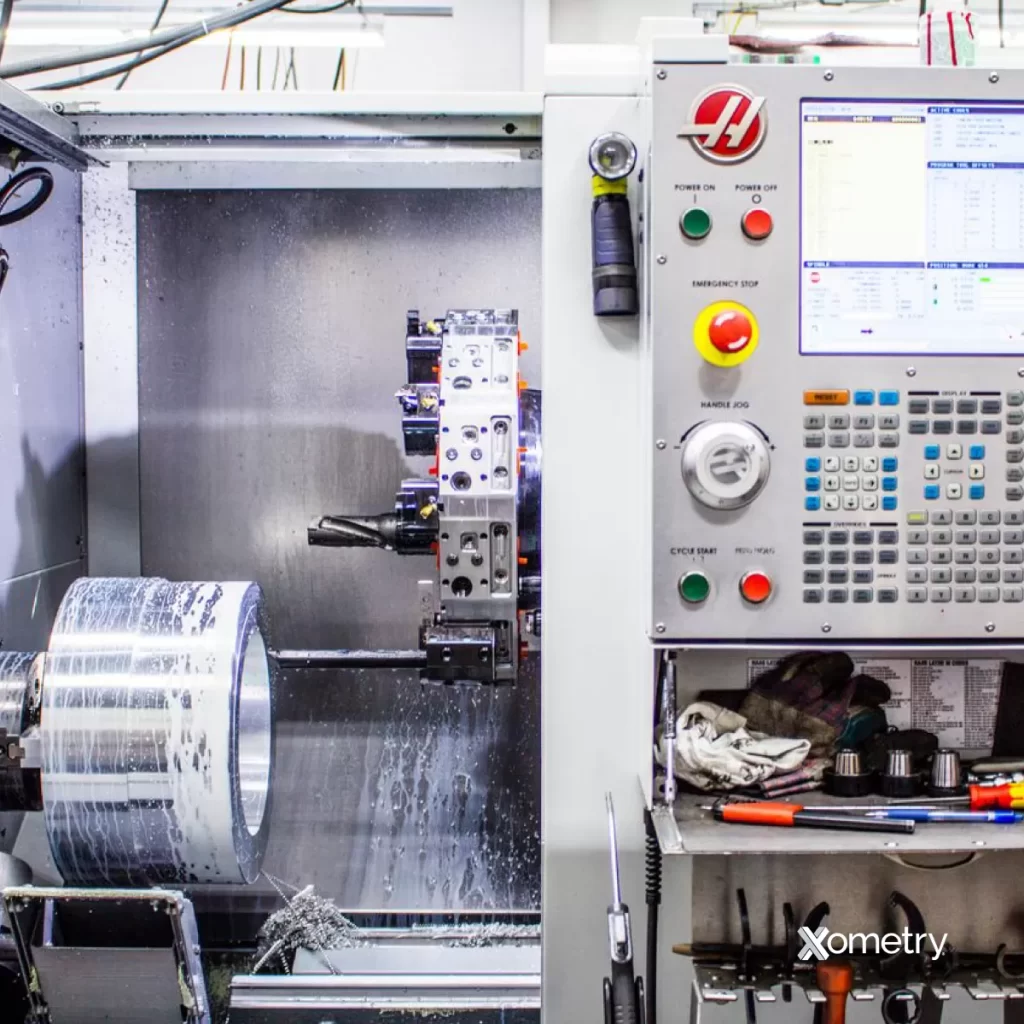

Rapid CNC machining is a subtractive manufacturing process where computer-controlled tools quickly remove material from a workpiece to create precise parts. Unlike traditional machining, rapid CNC machining focuses on speed and efficiency without sacrificing accuracy. It uses advanced automation and optimized toolpaths to deliver fast turnaround times, making it ideal for projects that require quick prototyping or low-volume production.

The key advantages of rapid CNC machining include:

- Automation that reduces manual setup and errors

- High precision for tight tolerance parts

- Fast processing speeds to meet tight deadlines

At HYCNC, we use cutting-edge CNC equipment and proprietary software to streamline the entire process—from design to finished part. This advanced technology enables rapid prototyping and on-demand production while maintaining consistent quality.

Let’s dive into the top rapid CNC machining questions to help you understand how this process fits various manufacturing needs.

Top 5 Common Rapid CNC Machining Questions

How Does Rapid CNC Machining Differ from Traditional CNC Machining

Rapid CNC machining is all about speed and efficiency without sacrificing quality. Unlike traditional CNC machining, which often involves longer setup times and manual quoting, rapid CNC uses automated quoting systems, optimized toolpaths, and streamlined workflows to accelerate every step of the process. This means parts move faster from design to production.

Turnaround times are a major difference. Rapid CNC machining is perfect for quick prototyping and small batch runs, often delivering in days rather than weeks. Traditional CNC tends to focus on larger production volumes where setup time is less of a concern.

At HYCNC, we leverage proprietary software designed to shorten the design-to-production cycle. Our system automates complex calculations and toolpath generation, helping us deliver fast and accurate results that fit the needs of industries requiring quick prototypes or urgent part replacements.

This focus on speed makes rapid CNC machining an ideal choice for customers who need precision CNC machining with a faster turnaround, without compromising on part quality or material options.

For more on how CNC machining works and why rapid services matter, check out our detailed CNC machining overview.

Materials Used in Rapid CNC Machining

Common Materials for Rapid CNC Machining

Rapid CNC machining works with a broad range of materials, making it flexible for many projects. The most common include:

- Metals: aluminum, titanium, stainless steel

- Plastics: ABS, POM, acrylic

- Composites: carbon fiber and other reinforced materials

Each material offers different benefits depending on what you need for your part or prototype.

Choosing Materials Based on Project Needs

When selecting materials for rapid CNC machining, think about factors like:

- Strength: Metals like titanium are great for durable, high-stress parts.

- Durability: Stainless steel offers resistance to wear and corrosion.

- Weight: Aluminum is lightweight but strong, perfect for aerospace or automotive prototypes.

- Finish and appearance: Acrylic or ABS plastic can provide better aesthetics for consumer products.

Balancing these will help meet your design goals and functional requirements.

HYCNC Material Inventory and Custom Sourcing

At HYCNC, we have an extensive material inventory ready to support rapid CNC machining projects. Plus, if you need something unique, we handle custom material sourcing to fit your specific needs. This ensures you get the right material — fast and hassle-free — whether for prototyping or low-volume production.

Choosing the right material is key for precision CNC machining; we’re here to help guide you every step of the way.

Typical Applications of Rapid CNC Machining

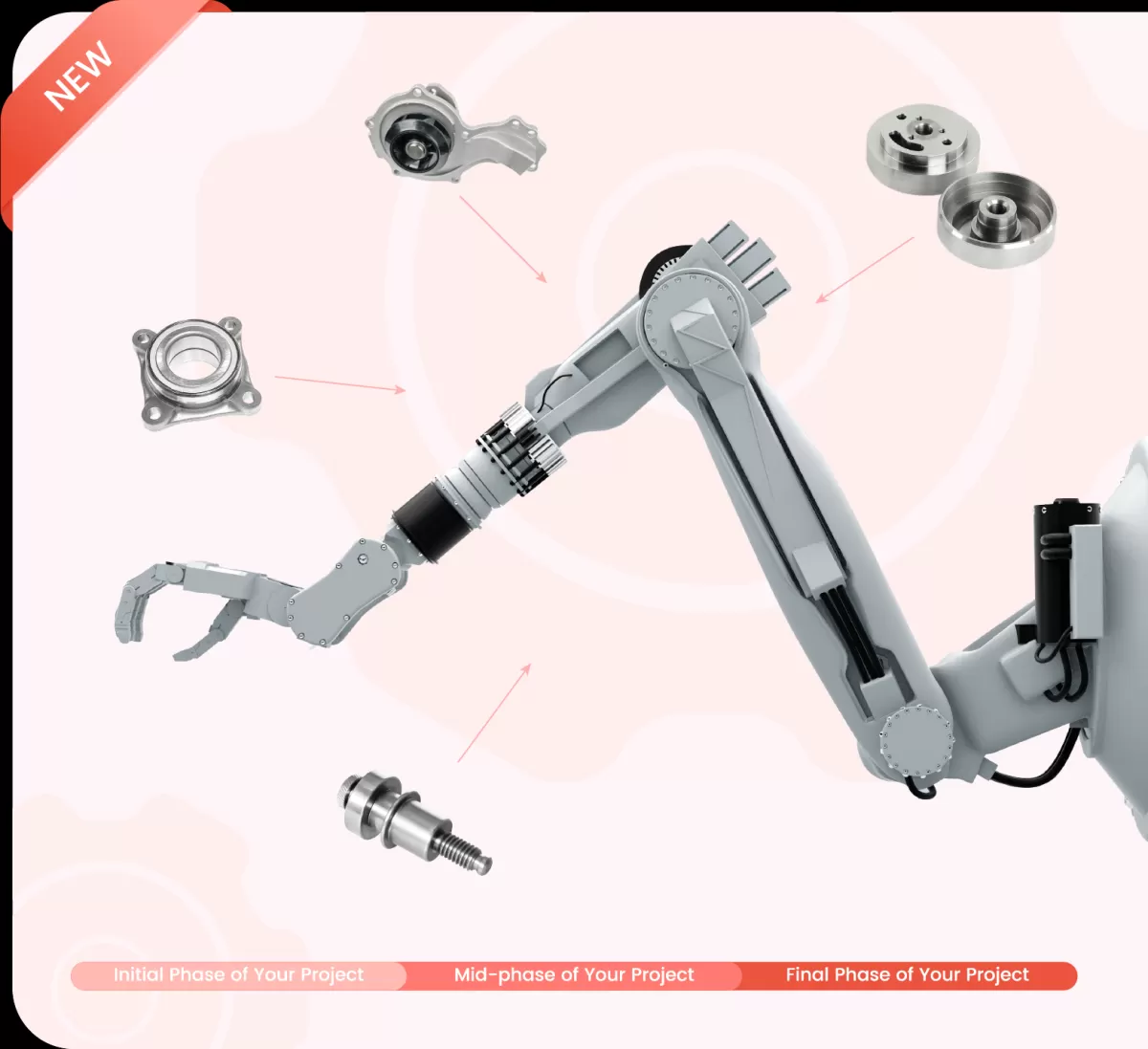

Rapid CNC machining is widely used across aerospace, automotive, medical, and consumer electronics industries. These sectors demand precision, quick turnarounds, and reliable quality, which rapid CNC machining delivers consistently.

Common Use Cases

- Prototyping: Quickly produce functional prototypes to test form, fit, and function before moving to large-scale production.

- End-use Parts: Manufacture small batches of high-quality parts ready for market, especially when traditional tooling costs are too high.

- Low-volume Production: Ideal for custom and limited runs where speed and accuracy are critical without committing to large quantities.

At HYCNC, we have extensive experience serving these industries with tailored rapid CNC machining solutions. Our advanced technology and skilled team ensure components meet exact specifications and are delivered on schedule. This makes us a trusted partner whether you need quick prototypes or production-ready parts.

For more details on our capabilities, check out our precision machining services.

How Does Rapid CNC Machining Compare to 3D Printing

When deciding between rapid CNC machining and 3D printing, it’s important to understand the core differences between these processes. CNC machining is a subtractive process, which means it removes material from a solid block using computer-controlled tools. In contrast, 3D printing is an additive process that builds parts layer by layer.

Speed Accuracy and Material Properties

- Speed: Rapid CNC machining often delivers parts faster than 3D printing, especially for metal components or when high precision is required. While 3D printing is great for rapid prototyping plastics and some metals, it can be slower for detailed or larger parts.

- Accuracy: CNC machining generally achieves tighter tolerances and finer surface finishes than most 3D printing methods. This is critical for parts where fit and function are non-negotiable.

- Material Properties: Machined parts maintain the original strength and durability of the bulk material, such as aluminum, titanium, or stainless steel. 3D printed parts, especially from plastics, may not offer the same mechanical properties or long-term stability.

When to Choose Rapid CNC Machining Over 3D Printing

- High-strength parts: Choose CNC machining for parts that must withstand heavy loads or harsh environments.

- Tight tolerances and finishes: CNC is your go-to for precision components requiring smooth surfaces.

- Metal parts and complex geometries: While 3D printing can handle some metals, CNC offers broader material options and reliable quality.

At HYCNC, we help clients decide the right process based on project needs. Our expertise in rapid prototyping CNC and precision machining means we guide you toward the most efficient, cost-effective solution—whether that’s fast CNC machining or 3D printing.

For more on how CNC stacks up in advanced industries, see our insights on precision machining.

Design Limitations of Rapid CNC Machining

While rapid CNC machining is fast and precise, it does come with some design limitations you should keep in mind to ensure smooth manufacturing and avoid costly delays.

Common Constraints in CNC Machining Design

- Tool Access: CNC tools need clear access to the part surfaces. Complex geometries with tight internal corners or deep cavities can be difficult or impossible to reach.

- Part Geometry: Overhangs or intricate shapes may require special setups or multiple fixtures, which can slow down production and increase costs.

- Minimum Feature Sizes: Features like small holes, thin walls, or fine grooves must meet minimum size requirements based on the tool’s diameter and material properties.

- Surface Finish Needs: Some finishes might require secondary operations if the geometry causes tool deflection or vibration.

Tips for Designing CNC Friendly Parts

- Avoid deep pockets or cavities that exceed the tool length or cause accessibility issues.

- Use rounded internal corners instead of sharp angles to match tool paths and reduce tool wear.

- Keep small holes and slots at or above the recommended minimum diameter for the chosen tool.

- Design parts with consistent wall thickness to minimize warping or distortion during machining.

- Simplify features where possible to speed up toolpaths and reduce machining time.

How HYCNC Supports Optimized CNC Designs

At HYCNC, we offer design-for-manufacturability (DFM) analysis to identify potential design issues early on. This service helps you:

- Get practical recommendations to improve your design for faster, cost-effective machining.

- Avoid surprises in production caused by inaccessible features or unsuitable geometries.

- Enhance the overall quality and precision of your rapid CNC machined parts.

Working with HYCNC ensures your designs are optimized to leverage the full benefits of rapid CNC machining. Learn more about our capabilities in CNC machining services.

Why Choose HYCNC for Rapid CNC Machining

When it comes to rapid CNC machining, HYCNC stands out for several key reasons. We offer fast quoting with clear, upfront pricing so you can plan your projects without delays. Our fleet of advanced CNC equipment ensures precision and speed on every job, whether it’s for prototype machining or small-to-mid volume production runs.

Our team of skilled engineers brings extensive experience to the table, handling even the most complex or tight-tolerance parts efficiently. Plus, HYCNC holds industry certifications that guarantee consistent quality control throughout the machining process. This means your parts meet rigorous standards every time.

We’re also equipped to manage custom CNC machining requests, from unusual materials to challenging designs. This flexibility makes us a trusted partner across industries like aerospace, automotive, and medical devices.

Contact HYCNC for a free quote today and discover how our rapid CNC machining services can speed up your production without sacrificing quality.

For more about our capabilities, check out our precision machining services.

FAQs About Rapid CNC Machining at HYCNC

How Fast Can HYCNC Deliver Rapid CNC Machined Parts

At HYCNC, fast turnaround is a priority. Depending on the project complexity and material, we can deliver parts in as little as 24 to 72 hours. Our automated quoting and optimized toolpaths help speed up the design-to-production process without sacrificing quality, making us a reliable choice for urgent rapid CNC machining needs.

What Industries Does HYCNC Serve with Rapid CNC Machining

We serve a wide range of industries, including:

- Aerospace

- Automotive

- Medical

- Consumer electronics

- Industrial manufacturing

Our experience across these sectors allows us to handle everything from prototyping to low-volume production with precision and speed.

Can HYCNC Handle Custom Material Requests for CNC Machining

Yes, we do. HYCNC offers an extensive material inventory including metals like aluminum, titanium, stainless steel, and various plastics. If your project requires custom or hard-to-source materials, we work closely with suppliers to meet your specific needs without delay.

How Does HYCNC Ensure Quality in Rapid CNC Machining

Quality is non-negotiable at HYCNC. We use:

- Advanced quality control systems

- Skilled engineers who monitor each step

- Design-for-manufacturability (DFM) analysis to catch potential issues early

This ensures your parts meet tight tolerances and industry standards every time.