Struggling to choose between anodizing and chemical film for your CNC-machined parts? The right surface finish can transform your project’s durability, aesthetics, and performance. As a CNC machining expert, I’ve seen how these finishes impact everything from aerospace components to electronics enclosures. In this guide, you’ll discover the key differences, benefits, and applications of anodizing versus chemical film, backed by real industry insights. Ready to make an informed choice for your next project? Let’s dive in!

What Is Anodizing

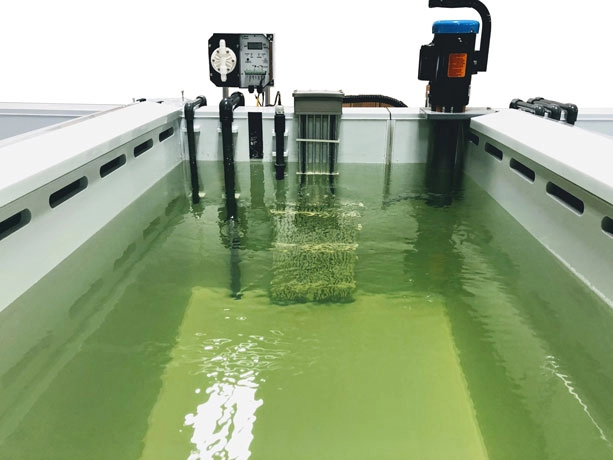

Anodizing is a popular aluminum surface finishing technique that uses an electrochemical process to create a durable oxide layer on metal parts. During anodizing, the aluminum part acts as the anode in a sulfuric acid bath. When electric current runs through the bath, it oxidizes the metal surface, forming a tough, corrosion-resistant coating that is integral to the metal itself.

Types of Anodizing

There are three common types of anodizing, each with unique features:

-

Type I (Chromic Acid Anodizing)

Produces a thin, flexible coating. It’s corrosion resistant and used when parts require precision or need to maintain tight tolerances.

-

Type II (Sulfuric Acid Anodizing)

The most common type. It creates a thicker oxide layer with good durability and aesthetic options. Ideal for general protection and coloring.

-

Type III (Hard Anodizing)

Creates a very thick, hard, and wear-resistant coating. It’s best for harsh environments, offering superior abrasion resistance and corrosion protection.

Benefits of Anodizing

Anodizing offers several valuable benefits:

- Durability: The oxide layer is hard and long-lasting.

- Corrosion Resistance: Protects metal from rust and environmental damage.

- Aesthetic Versatility: Available in a variety of colors through dyes or natural finishes.

- Wear Resistance: Especially with Type III hard anodizing, parts handle heavy wear.

Common Applications

Anodized finishes are widely used across many industries:

- Aerospace components like structural parts and panels

- Architectural elements such as window frames and decorative facades

- Consumer electronics, including smartphone bodies and laptop cases

At HYCNC, we know how anodizing can add value, durability, and style to your aluminum CNC projects.

What Is Chemical Film Chem Film Alodine

Chemical film, also known as chem film or Alodine, is a type of chemical conversion coating applied to metal surfaces, mainly aluminum. Unlike anodizing, it doesn’t use electricity. Instead, the metal is dipped into a chromate solution where a thin, protective layer forms through a chemical reaction. This layer improves corrosion resistance and prepares the surface for painting or bonding.

Types of Chemical Film

- Class 1A: Provides good corrosion protection and improves paint adhesion. Common for general use.

- Class 3: Offers superior corrosion resistance, often used in more demanding applications and military specs.

There are environmental concerns around chemical films, mainly due to the use of chromium. Hexavalent chromium, which is toxic, is being phased out in favor of the safer trivalent chromium versions that still provide effective protection but with fewer health risks.

Key Benefits

- Electrical Conductivity: Chem film maintains good conductivity, making it ideal for parts needing electrical grounding.

- Cost Effective: It’s less expensive and quicker than anodizing, which is great for budget-sensitive projects.

- Paint Adhesion: Works well as a primer layer, helping paint and coatings stick better to metal surfaces.

Common Applications

You’ll find chemical film often used in:

- Electronics: For grounding and protective coatings.

- Automotive Parts: On components where corrosion resistance and conductivity matter.

- Military Hardware: Where both protection and specific performance standards must be met.

Anodizing vs Chemical Film A Detailed Comparison

When deciding between anodizing and chemical film, it helps to understand how they differ in process, performance, cost, and environmental impact.

Process Differences

- Anodizing uses an electrochemical oxidation process where aluminum parts act as the anode in a sulfuric acid bath. This requires specialized equipment and takes longer due to the buildup of a durable oxide layer.

- Chemical film (also called chem film or Alodine) is a chemical conversion coating applied without electricity. It’s quicker and uses simpler equipment.

Performance Comparison

Corrosion Resistance

- Anodizing creates a thicker, harder oxide layer that offers superior corrosion protection.

- Chemical film produces a thinner coating, giving decent corrosion resistance but not as tough as anodizing.

Durability and Wear Resistance

- Anodized surfaces are much harder and more wear-resistant—ideal for parts facing friction or harsh environments.

- Chem film provides a softer layer, better for basic protection but less durable under heavy use.

Electrical Conductivity

- Chem film is known for maintaining good electrical conductivity, making it common in electronics and military gear.

- Anodizing forms an insulating oxide layer, so it’s not ideal when conductivity is important.

Aesthetic Options

- Anodizing offers a wide range of colors and finishes, letting you customize appearance.

- Chemical film finishes are limited mostly to clear or gold hues.

Cost and Production Considerations

- Chem film is generally cheaper and well-suited for small batch runs or quick turnarounds.

- Anodizing can be more costly upfront but scales better for larger production runs demanding higher durability.

Environmental Impact

- Anodizing is considered eco-friendlier since it uses fewer hazardous chemicals and produces less waste.

- Chemical film often involves chromate-based coatings, which raise regulatory and disposal concerns, especially if hexavalent chromium is used.

In , anodizing is your go-to for durability and looks, while chemical film works well where conductivity and cost matter most. Understanding these differences helps make the right choice for your metal finishing needs.

Choosing the Right Finish for Your CNC Project

Picking the perfect surface finish for your CNC part comes down to a few key factors:

- Application requirements: What will the part face—wear, corrosion, or electrical needs?

- Budget: How much are you willing to spend?

- Production volume: Are you making a few parts or thousands?

- Material type: Different metals react differently to anodizing and chemical film.

When to Choose Anodizing

Go with anodizing if you need:

- High durability and wear resistance

- Excellent corrosion protection, especially in tough environments like aerospace or outdoor use

- Custom colors or a great-looking finish for architectural or consumer products

- Long-term performance without a lot of maintenance

When to Choose Chemical Film

Chemical film (also known as Chem Film or Alodine) is your best bet if you want:

- Electrical conductivity, such as for electronics or connectors

- A cost-effective finish especially for small runs or tight budgets

- A finish that works as a paint primer or corrosion base layer

- Quick application without the need for electricity or complex equipment

Case Study: How HYCNC Helped Select the Optimal Finish

A recent aerospace client needed parts that withstand harsh conditions but also maintain lightweight properties. After discussing their needs, HYCNC recommended type III hard anodizing for maximum corrosion and wear resistance. This choice extended their part life and met strict industry standards, all while providing a strong aesthetic finish.

If you’re unsure which finish fits your project, HYCNC can help you evaluate your options and pick the best surface treatment for your CNC parts—saving you time, money, and headaches down the line.

For more on anodizing basics and applications, check out our detailed guide on Anodizing Aluminum and How It’s Used in Laser Cutting.

HYCNC’s Expertise in Surface Finishing

At HYCNC, we specialize in CNC machining with a strong focus on high-quality surface finishing. Whether you need anodizing or chemical film coatings, we provide customized solutions tailored to your specific project needs. Our team understands the nuances of aluminum surface finishing and other metals, delivering finishes that meet both aesthetic and functional demands.

We’re committed to precision and quality, following strict industry standards and MilSpec requirements. This ensures your parts not only look great but perform reliably in demanding environments like aerospace, automotive, and electronics.

Need help choosing the right finish or want a reliable partner for consistent results? Contact HYCNC today for tailored CNC machining and finishing solutions built around your goals.

FAQs About Anodizing and Chemical Film

What metals can be anodized or chem filmed?

Anodizing mainly works on aluminum and its alloys. Chemical film (also called chem film or Alodine) can be applied to aluminum, magnesium, and zinc alloys. Steel and stainless steel usually don’t take these finishes well.

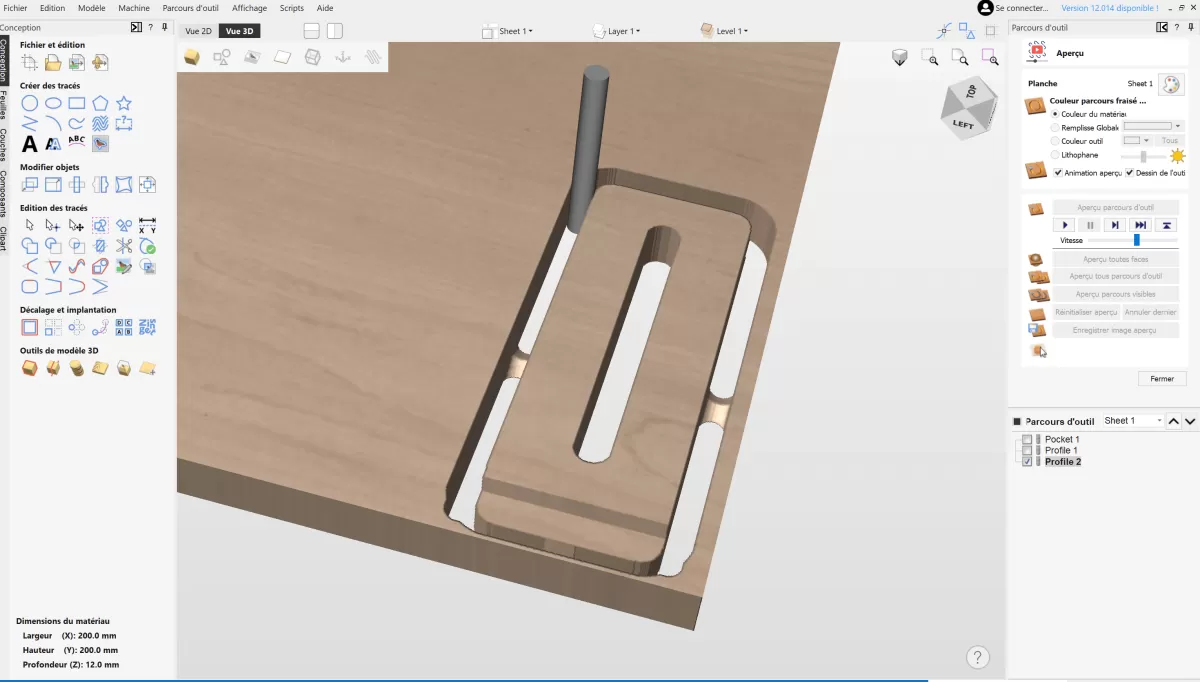

How does anodizing affect part dimensions compared to chem film?

Anodizing creates a thicker oxide layer that adds slight thickness to the part surface. That means small dimensional changes you may need to consider. Chem film coatings are much thinner and have minimal impact on part dimensions.

Is chemical film environmentally safe?

Traditional chemical film used hexavalent chromium, which is toxic and regulated. Today, many providers use trivalent chromium formulas that are safer and better for the environment. Still, it’s good to ask about the specific chem film type being used.

Can anodizing and chemical film be combined on the same part?

Usually, these finishes aren’t combined because anodizing forms its own hard oxide layer, and chem film is a thinner conversion coating for aluminum. But sometimes chem film is applied before painting or sealing anodized parts to improve adhesion.

How does HYCNC ensure quality in surface finishing?

At HYCNC, we focus on precision and consistent quality. We use industry-standard processes and MilSpec-compliant finishes. Every part goes through strict inspection before delivery to meet your specifications and ensure corrosion resistance, durability, and the exact surface finish you need.

If you have questions about anodizing or chemical film for your project, give us a call. We’re here to help you pick the right finish and get reliable results.