What Are CNC Routers and Traditional Tools

When comparing CNC routers vs manual tools, it’s essential to understand what sets them apart and how they serve different manufacturing needs.

Defining CNC Routers and Traditional Tools

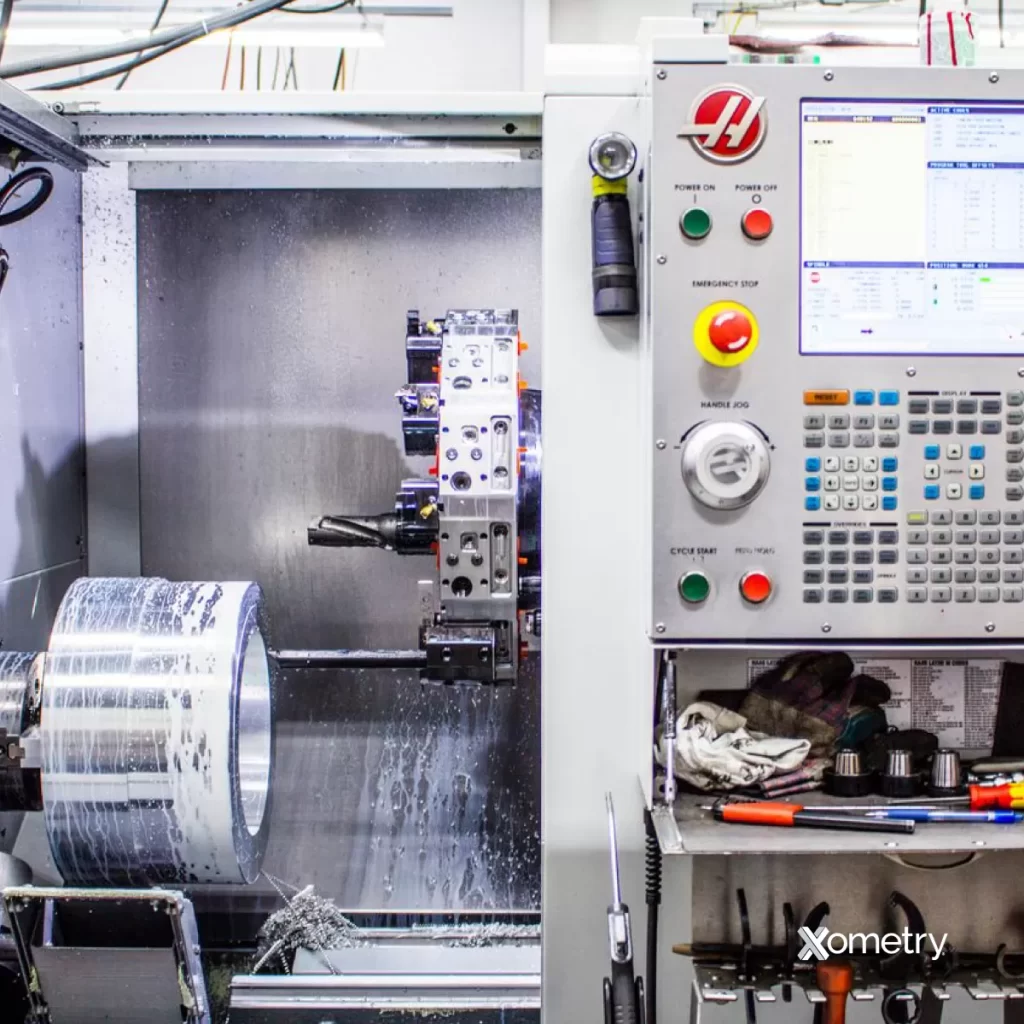

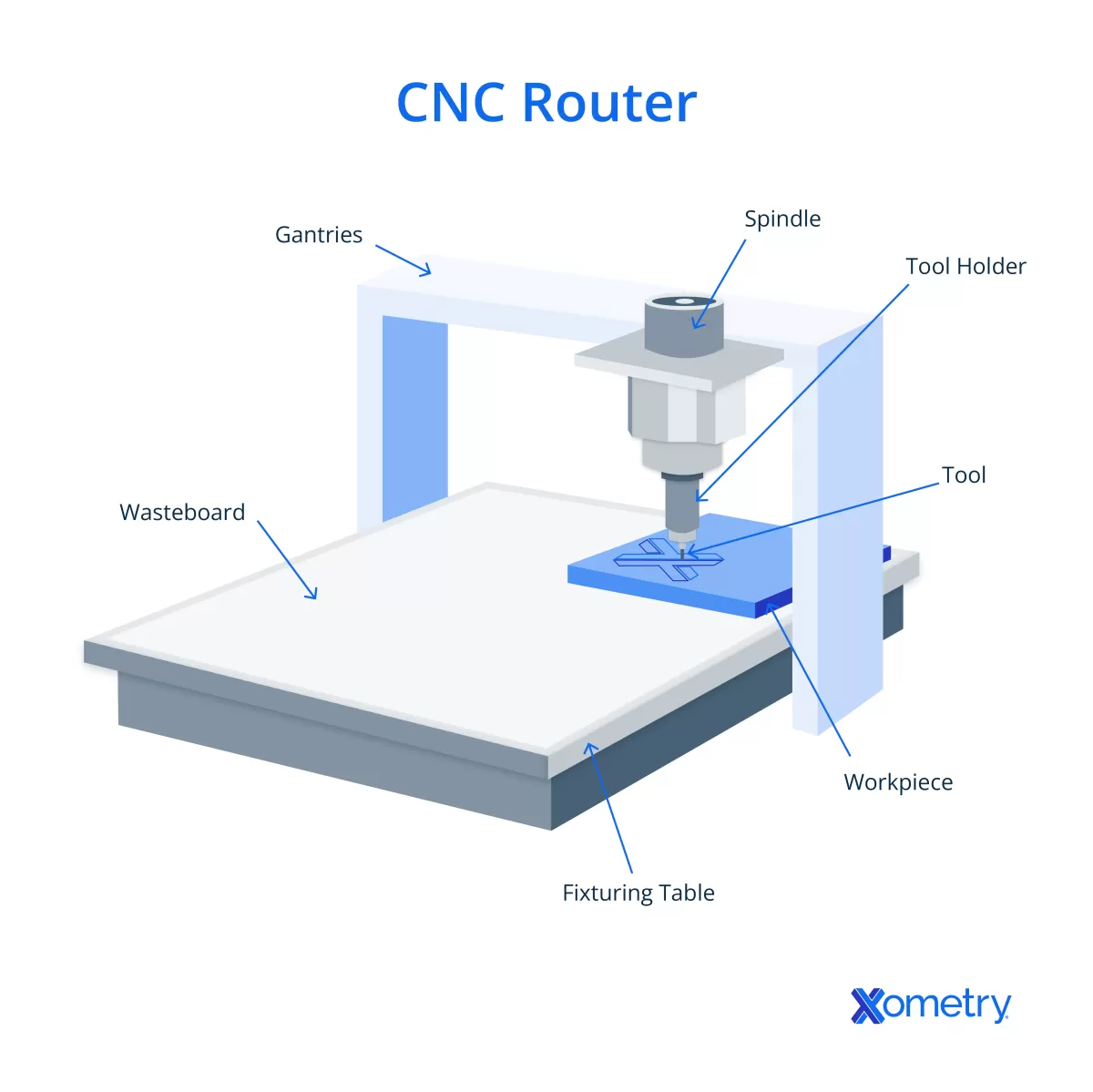

A CNC router is a computer-controlled cutting machine designed to carve, cut, and shape various materials like wood, plastic, aluminum, and composites. It uses automated precision driven by software, allowing for unmatched accuracy and repeatability in designs. These machines represent the forefront of modern manufacturing technology, integrating automation in manufacturing to deliver consistent results with minimal manual intervention.

On the other hand, traditional tools refer to hand-operated or manually powered equipment used in woodworking and metalworking. Think of saws, chisels, drills, and lathes that rely heavily on the skill and experience of the operator. While they offer flexibility for custom, small-batch projects, traditional tools often come with limitations in consistency, speed, and precision.

Key Differences Between CNC Routers and Traditional Tools

-

Precision and Repeatability

CNC routers offer high CNC router precision through computer guidance, producing the same cut repeatedly with exact measurements—something manual tools can struggle to achieve.

-

Automation and Efficiency

Unlike traditional woodworking tools that require constant user input, CNC routers run on programmed commands, boosting CNC router efficiency and reducing human error.

-

Material Versatility

CNC routers can handle a broader range of materials with ease, making them ideal for diverse applications, whereas traditional tools might be limited by the user’s skills or specific tool constraints.

HYCNC Services and Expertise

At HYCNC, we specialize in providing cost-effective CNC solutions tailored to meet the evolving demands of the manufacturing industry in the US. Our CNC machining and CNC service offerings ensure you get access to top-tier equipment, expert guidance, and precision-driven results that outpace traditional methods.

Whether you’re transitioning from traditional tools or starting fresh with CNC technology, HYCNC supports your journey with modern solutions designed to improve productivity, safety, and quality across various industries.

Key Advantages of CNC Routers Over Traditional Tools

When comparing CNC routers to traditional woodworking tools, there are several clear benefits that make CNC the preferred choice in many industries.

Unmatched Precision and Consistency

One of the biggest advantages of a CNC router is its ability to deliver high precision and consistent results every single time. Unlike manual tools, which rely heavily on an operator’s skill, CNC machines follow exact programmed paths. This means parts come out uniform, reducing mistakes and waste—a major win for businesses focused on quality.

Enhanced Speed and Efficiency

CNC router efficiency far surpasses what traditional tools can offer. Automated controls allow for faster cutting, drilling, and shaping with minimal downtime. What might take hours by hand can often be done in minutes by a CNC. This boost in productivity lets companies scale work without needing more workers or hours.

Versatility Across Materials

A key strength of CNC routers is their ability to work with a wide range of materials, including wood, plastics, composites, and soft metals. This material versatility means fewer machine changes and more flexibility in the work process. Whether it’s cabinetry, signage, or custom components, CNC adapts quickly where traditional tools may be limited.

Reduced Labor Costs and Skill Requirements

Because CNC machines automate complex operations, they cut down the need for highly specialized labor. Operators don’t have to handcraft every detail or master every tool, which can lower training time and labor costs. Plus, there’s less chance of injury or fatigue affecting the final product.

Safety and Reduced Risk

Modern CNC router safety features reduce the risk of accidents commonly associated with traditional woodworking tools. Since the process is computer-controlled, there is less direct contact with blades or cutting surfaces. This safer environment makes it easier to meet workplace safety standards and protect your team.

Cost Effectiveness Over Time

While the initial investment in a CNC router might be higher, the long-term savings are significant. Benefits like reduced material waste, faster production times, and lower labor costs lead to better return on investment. For businesses looking for cost-effective CNC solutions, it’s a strategic move that pays off.

Overall, CNC routers combine precision, speed, flexibility, and safety to outshine traditional manual tools in modern manufacturing and woodworking settings.

Limitations of CNC Routers vs Traditional Tools

While CNC routers offer many benefits, they do have some limitations compared to traditional tools. It’s important to understand these to choose the right approach for your project.

Higher Initial Investment and Setup

One of the biggest drawbacks of CNC routers is the cost. The machines require a significant upfront investment, including software and training costs. Unlike traditional woodworking tools, which you can often use with minimal setup, CNC routers need time to properly program and configure before starting production.

Less Flexibility for Small or Simple Jobs

For small batches or simple cuts, traditional tools can be faster and more practical. CNC routers excel in repetitive, complex tasks but can feel less efficient when you only need a few basic cuts or adjustments on the fly. Manual tools allow for quick changes without stopping to reprogram the machine.

Maintenance and Technical Skill Requirements

Operating and maintaining a CNC router demands technical knowledge. You need trained operators familiar with the software and mechanics, which can mean extra labor or ongoing training costs. Traditional tools generally require less maintenance and are easier for a wide range of workers to use.

Size and Space Considerations

CNC routers tend to be larger and require dedicated workshop space and proper ventilation. Small workshops or businesses might find it challenging to accommodate these machines compared to handheld or bench-top traditional tools.

Material and Design Limitations

While CNC routers handle a variety of materials—increasing material versatility—some very thick or dense materials might still be easier to work with using traditional cutting or shaping tools. Additionally, highly customized or one-off projects sometimes benefit from the hands-on adaptability of manual tools.

Balancing these limitations with the many advantages of CNC machines will help you make the right decision. For deeper insights into tooling options, you can check our guide on tools for internal threads in CNC turning and milling.

Real World Applications How CNC Routers Transform Industries

CNC routers have revolutionized many industries by bringing precision, speed, and efficiency that traditional tools just can’t match. Here’s how they’re making a big impact across various sectors:

Woodworking and Furniture Making

CNC routers bring unmatched precision to woodworking. They carve intricate designs with consistent quality, speeding up production. Whether it’s custom furniture or cabinetry, the automation means less waste and faster turnaround times compared to traditional woodworking tools.

Sign Making and Advertising

For the sign industry, CNC routers handle materials like wood, plastic, and metal with ease. This material versatility lets businesses create detailed signage quickly and accurately, improving the overall look and durability while reducing manual error.

Manufacturing and Prototyping

In manufacturing, automation in manufacturing with CNC routers means parts are produced faster and with tight tolerances. This is huge for prototyping and small batch runs, where every detail matters, and the CNC router precision ensures each piece meets exact specs.

Aerospace and Automotive

Industries like aerospace and automotive rely on CNC routers for parts that require high accuracy and durability. From complex components to customized parts, CNC machines improve product consistency and reduce lead times, making them a smart choice for modern manufacturing technology needs.

Education and Art

CNC routers also find their place in schools and art studios. They allow students and artists to experiment with shapes and designs that would be hard or dangerous to do by hand, blending creativity with technology safely and efficiently.

In short, CNC routers drive innovation across different fields by improving quality, cutting down labor, and expanding what’s possible with various materials. This makes them a valuable tool for businesses across the US aiming for cost-effective CNC solutions and improved production capabilities.

Why Choose HYCNC for Your CNC Router Needs

When it comes to CNC router services, HYCNC stands out as a trusted partner for businesses across the United States. We combine modern manufacturing technology with extensive industry experience to deliver cost-effective CNC solutions tailored to your specific needs.

Here’s why HYCNC is the smart choice for your CNC router projects:

-

Precision and Quality You Can Rely On

We use advanced CNC equipment that ensures unmatched CNC router precision for every job. This commitment to accuracy means your parts come out consistently perfect, reducing waste and saving you money.

-

Wide Material Versatility

Our CNC routers handle everything from wood and plastics to metals, offering tremendous material versatility CNC users need today. Whether you’re prototyping or producing, we adapt to your material requirements quickly.

-

Speed and Efficiency

HYCNC’s automated processes boost turnaround times, helping you meet tight deadlines without compromising quality. Our efficient workflow supports projects of all sizes, keeping your production on schedule.

-

Experienced Support and Consultation

We don’t just run machines; we guide you through the best milling and cutting strategies. Our team understands CNC vs manual tools’ pros and cons and helps you maximize the benefits of automation in manufacturing.

-

Safety and Reliability

With a strong focus on CNC router safety features, we maintain strict operational standards that protect your orders and our people. This approach minimizes risk and maintains steady production flows.

-

Competitive Pricing Over Time

By reducing labor costs and increasing process efficiency, HYCNC provides cost-effective CNC solutions that deliver savings in the long run, making CNC machining accessible without breaking your budget.

For more specialized metal parts or internal threading needs, check out our insights on CNC metal cutting tools and tools for internal threads in CNC turning and milling to see how our services cover a broad range of CNC machining challenges.

Choosing HYCNC means partnering with a reliable CNC service provider who understands your business goals and delivers consistent, precise, and efficient results every time.