Are you struggling to estimate sheet metal fabrication costs for your next project? Getting a clear picture of pricing can make or break your budget and timeline.

As a leader in CNC sheet metal fabrication, HYCNC knows that understanding costs is key to delivering high-quality parts without overspending. With years of industry expertise, we’re here to share practical insights that go beyond the basics.

In this 2025 cost guide, you’ll discover the factors driving sheet metal fabrication pricing, proven tips to save money, and how HYCNC’s precision processes deliver unmatched value. Whether you’re designing prototypes or scaling production, this guide will empower you to make smart, cost-effective decisions.

Let’s dive in!

What Is Sheet Metal Fabrication

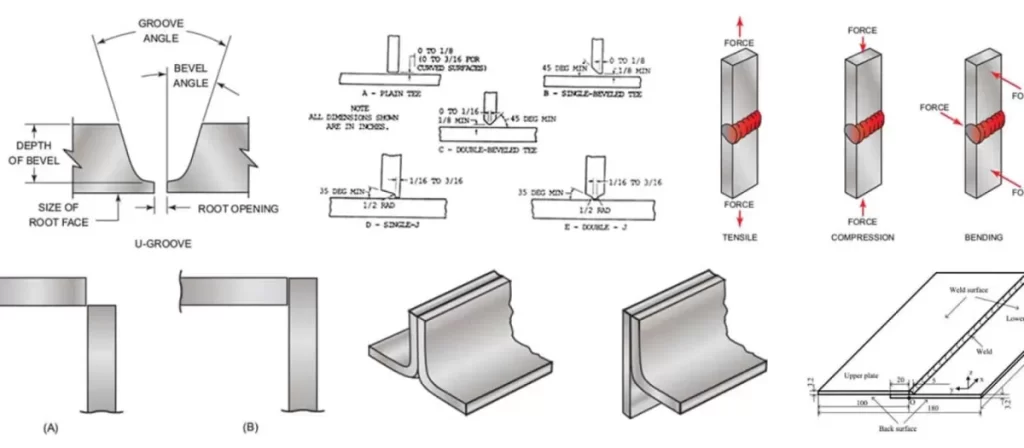

Sheet metal fabrication is the process of shaping, cutting, and assembling thin metal sheets into finished products or components. It involves a combination of various techniques such as cutting, bending, punching, welding, and machining to transform flat metal sheets into precise and functional parts. Common materials used include steel, aluminum, copper, and stainless steel.

This process is widely applied across industries like automotive, aerospace, construction, electronics, and appliance manufacturing. Whether creating structural frameworks, enclosures, brackets, or intricate components, sheet metal fabrication enables efficient production of durable and lightweight parts tailored to specific design requirements. Understanding these fundamental processes helps in accurately estimating sheet metal fabrication costs and optimizing designs for manufacturability.

Key Factors Affecting Sheet Metal Fabrication Costs

When figuring out sheet metal fabrication costs, several key factors come into play. Understanding these can help you control expenses and get a fair price.

Material Costs

The type and thickness of metal you choose directly impact costs. Common materials like steel, aluminum, and stainless steel vary in price. Using standard gauges and stock sizes usually saves money.

Labor Costs

Labor makes up a big chunk of sheet metal fabrication costs. Skilled workers operating CNC machines or handling bending, cutting, and welding all add to the price. Complexity and the time needed affect labor charges.

Machining and Process Costs

Each process—whether it’s CNC punching, laser cutting, bending, or welding—has its own cost. More machining steps and tighter tolerances can raise prices. Specialized processes or custom tooling also cost more.

Design Complexity

A simple design is cheaper to produce than a complex one. Intricate shapes, tight bends, or fine details require extra work and slow down production, increasing costs.

Finishing and Assembly

Surface finishes like powder coating, painting, or plating add to expenses. If your project needs assembly, that’s another labor step to budget for.

Shipping and Logistics

Finally, where and how you ship your finished parts affects the overall cost. Local fabrication shops can reduce shipping fees and lead times, while longer-distance deliveries add to expenses.

Keeping these factors in mind helps you better estimate sheet metal fabrication costs and avoid surprises.

How to Calculate Sheet Metal Fabrication Costs

Calculating sheet metal fabrication costs might seem tricky, but breaking it down step by step makes it manageable. Here’s how you can estimate costs accurately:

Step by Step Cost Estimation

-

Material Cost

Start with the price of the raw metal. Factor in the type (steel, aluminum, copper) and how much material your project needs.

-

Labor Cost

Include wages for workers handling cutting, forming, welding, and assembly.

-

Machining and Processing Costs

Account for CNC machining, punching, bending, and other processes. These depend on how complex or simple your design is.

-

Finishing and Assembly

Costs for painting, powder coating, plating, or assembling multiple parts should be added here.

-

Shipping and Logistics

Don’t forget transportation costs, especially if your fabricator is out of state or offers expedited shipping.

Example Cost Breakdown

For a small aluminum enclosure, the cost might look like this:

| Cost Item | Estimated Cost |

|---|---|

| Material | $50 |

| Labor | $75 |

| CNC Machining | $40 |

| Finishing (Powder Coating) | $30 |

| Shipping | $20 |

| Total | $215 |

Cost Calculator Tools

Using online metal fabrication cost calculators can speed up rough estimates. They allow you to enter material type, thickness, part size, and processes, giving a quick price range. While not 100% accurate, they’re great for initial budgeting.

Collaborating for Accurate Quotes

The best way to nail precise sheet metal fabrication costs is by working closely with your fabricator. Share your design files and ask for detailed quotes. Good fabricators can provide feedback on how design changes impact pricing and suggest ways to optimize costs before production begins.

By understanding and calculating these costs carefully, you get a clear picture of your project budget and avoid surprises down the line.

6 Proven Tips to Reduce Sheet Metal Fabrication Costs

Keeping sheet metal fabrication costs down doesn’t have to be complicated. Here are six straightforward tips you can use to save money without sacrificing quality.

Use standard material gauges and stock sizes

Sticking to common thicknesses and sizes cuts down on waste and speeds up production. Custom sizes mean extra cutting and handling, which adds to your cost.

Simplify designs to reduce machining time

Complex shapes and tight tolerances take longer on CNC machines and drive up precision CNC fabrication pricing. A simpler design often means less machining, fewer tool changes, and faster turnaround.

Opt for cost effective finishes

Not every project needs high-end coatings or treatments. Choose finishes that meet your functional needs but don’t overdo it. This can significantly reduce your sheet metal prototyping costs and final price.

Leverage bulk ordering discounts

Ordering larger quantities usually translates into better pricing per part. If your timeline allows, batch your orders to benefit from volume discounts and reduce your overall sheet metal fabrication costs.

Partner with an all-in-one fabricator

Working with a company that handles everything from CNC machining to finishing and assembly cuts down on multiple vendor fees and shipping. This streamlines your project and often saves money.

Use design for manufacturability analysis

Early collaboration with your fabricator to review your design helps spot cost-saving opportunities. Adjusting designs upfront based on fabricator feedback optimizes sheet metal production costs and improves efficiency.

By applying these tips, you can confidently reduce your sheet metal fabrication expenses while keeping quality and delivery on point.

Why Choose HYCNC for Your Sheet Metal Fabrication Needs

When it comes to sheet metal fabrication costs, choosing the right partner makes all the difference. At HYCNC, we bring advanced CNC capabilities and state-of-the-art equipment to deliver precision and consistency on every project. Our in-house processes help keep your costs down by reducing outsourcing and streamlining production. We also provide design for manufacturability (DFM) feedback early in the process to optimize your sheet metal design, helping you avoid costly revisions later.

Need quick answers? Our fast quoting and prototyping services make it easy to get your project started without delays. Plus, HYCNC supports clients across the US with a global reach combined with localized support, so you get the personalized service your project deserves.

Ready to optimize your sheet metal fabrication costs with a trusted expert? Get your free quote from HYCNC today and experience efficient, cost-effective precision CNC fabrication tailored for your needs.