Understanding Tack Welding

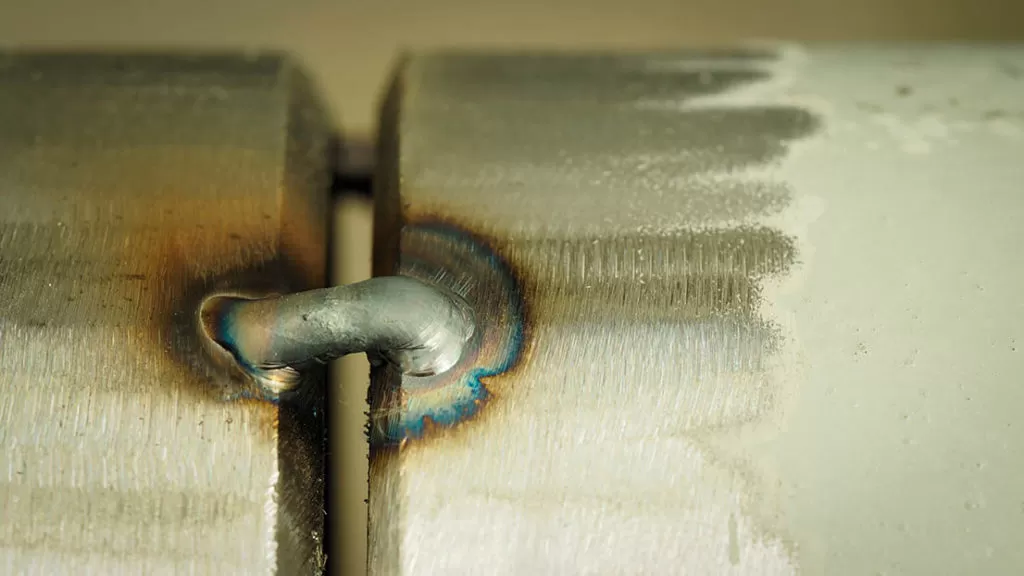

Tack welding is a welding technique used to create small, temporary welds that hold metal parts together in precise alignment before the final, permanent weld is applied. Think of tack welds as the “placeholders” in metal fabrication—they keep components stable and properly positioned during CNC machining or other welding processes.

Definition and Purpose

A tack weld is a quick, low-heat weld applied at specific points along a joint. Its main purpose is to hold parts firmly in place so that when the permanent weld is done, the entire assembly doesn’t shift or warp. This precision welding step is crucial in industries where accuracy and structural integrity matter, such as automotive welding and shipbuilding welding.

How Tack Welding Works

Tack welding works by applying just enough heat and filler material to fuse the metals at small, intermittent spots. The weld points are typically spaced inches apart, depending on the size and type of the metal pieces. This technique sets the foundation for perfect weld joint preparation, ensuring that the final weld runs smoothly without defects.

Tack Welding vs Permanent Welding

While permanent welding aims to create a strong, continuous bond between metals for long-lasting durability, tack welding is temporary and less robust. Tack welds are not meant to bear heavy stress or loads—they are simply there to maintain correct alignment during the welding process. In contrast, permanent welds provide the full strength and finish required in the final product.

By understanding these core differences, it becomes clear why tack welding is an essential step in any precision welding or CNC service operation, laying the groundwork for success in the overall metal fabrication process. For a deeper dive into related welding techniques, check out our guide on TIG welding process.

Applications of Tack Welding in CNC Machining

Tack welding plays a crucial role in CNC machining by holding parts in place before permanent welding or machining begins. It’s all about creating temporary welds that keep metal pieces aligned during the cutting, shaping, or drilling process. This precision welding step helps maintain tight tolerances and ensures the parts don’t shift, which is critical for achieving a quality surface finish and meeting design specs.

Industries Using Tack Welding

You’ll find tack welding widely used across several industries here in the U.S., including:

- Automotive welding – holding components together during chassis and body assembly before final welding.

- Shipbuilding welding – securing heavy metal sections to ensure proper fit in large hull assemblies.

- Metal fabrication – building frames, supports, and structures that require accurate alignment.

- Aerospace, manufacturing, and construction also depend on tack welds to keep work-in-progress stable.

Role of Tack Welding in CNC Processing

In CNC machining, tack welding ensures parts are fixed and won’t move under the stresses of milling or cutting. It supports:

- Weld joint preparation by stabilizing components.

- Reducing the chance of warping or distortion during machining.

- Faster changeovers and more efficient workflows by allowing quick adjustments before permanent welds.

Real World Case Studies

At HYCNC, we’ve seen how tack welding can save time and improve part quality across projects:

- For a local automotive supplier, tack welded frames allowed CNC machinery to cut with perfect precision without parts shifting, reducing scrap rates dramatically.

- In shipbuilding, tack welds held large steel plates together during cutting and fitting, speeding up assembly without sacrificing accuracy.

These examples highlight how essential tack welding is to reliable CNC machining workflows in practical, everyday manufacturing here in the U.S.

Benefits and Drawbacks of Tack Welding

Advantages of Tack Welding

Tack welding offers several key benefits, especially in CNC machining and metal fabrication:

- Precise Alignment: Tack welds hold parts firmly in place, ensuring perfect weld joint preparation before the final, permanent welding.

- Saves Time: Tack welding creates temporary welds quickly, speeding up the overall welding process without compromising accuracy.

- Reduces Warping: By securing components early, tack welding minimizes movement and distortion during permanent welds.

- Flexibility: It allows for adjustments before completing the final weld, which is critical in complex assemblies.

- Cost-Effective: Since tack welds are small and require less material, they help keep welding costs down while maintaining quality.

Potential Challenges of Tack Welding

Despite its advantages, tack welding comes with a few challenges:

- Weak Temporary Joints: Tack welds are not meant to withstand heavy loads, so relying on them beyond their purpose can cause failures.

- Risk of Cracking: Poor tack welds can lead to cracks during the final welding process or under stress.

- Inconsistent Sizes: Uneven tack welds can affect alignment, causing issues in the final weld quality.

- Heat Build-up: Excessive heat during tack welding can lead to distortion or weaken surrounding metal parts.

How HYCNC Mitigates Tack Welding Challenges

At HYCNC, we understand these challenges and focus on delivering high-quality tack welding services by:

- Using Precision Welding Equipment: Our advanced CNC machinery ensures consistent, accurate tack welds every time.

- Following Best Practices: We follow strict weld joint preparation steps to avoid cracks and maintain alignment through every stage.

- Regular Quality Checks: We inspect tack welds closely to catch inconsistencies and prevent defects early.

- Balancing Heat Input: HYCNC controls heat levels during both tack and final welds to reduce distortion and maintain surface finish.

Let us bring our expertise in precision tack welding to your next project. If you’re interested in learning more about proper welding joints, check out our article on 5 basic types of welding joints for additional insights.

Tack Welding Techniques and Best Practices

Key Techniques

Successful tack welding starts with the right techniques. Here’s what matters most:

- Proper Weld Joint Preparation: Clean and align metal pieces carefully before welding to ensure solid and stable tack welds.

- Choosing the Right Welding Method: MIG and TIG welding are common for tack welding, each with its strengths. MIG is faster, TIG offers more precision.

- Control Heat Input: Apply enough heat to join the metals but avoid overheating, which can cause warping or weak joints.

- Short Welds: Tack welds should be small and spaced to hold parts temporarily without stressing the metal.

Best Practices for High Quality Tack Welds

To ensure tack welds hold up during CNC machining and beyond:

- Use consistent tack size and spacing to keep parts securely in place.

- Always check alignment after tacking before completing the permanent weld.

- Use clean, rust-free metals to prevent weak spots.

- Ensure proper shielding gas coverage in MIG or TIG to avoid contamination.

- Follow manufacturer guidelines for amperage and travel speed.

Common Mistakes to Avoid

Avoid these pitfalls to maintain weld quality:

- Over-tacking: Applying welds that are too large or too many can distort the metal.

- Ignoring alignment checks: Skipping this leads to poor fit-up and extra work later.

- Excessive heat input: Can cause cracking or warping.

- Poor surface prep: Dirt or rust weakens tack welds.

- Not spacing tack welds properly: Too close or too far apart reduces structural support.

For more detailed guidance on types of tack welds and how to prevent common issues, check out this resource on types of tack welds and tips to prevent cracking in tack welds.

Why Choose HYCNC for Tack Welding Services

At HYCNC, we understand how critical precision welding is for quality CNC machining projects. Our tack welding services are designed to provide strong, reliable temporary welds that keep your parts perfectly aligned during the manufacturing process. We use advanced MIG and TIG welding techniques tailored to your metal fabrication needs, ensuring every weld joint is prepared and executed with care.

Here’s why HYCNC stands out for tack welding:

-

Expertise in CNC Processing

We combine our deep knowledge of CNC machining with skilled welders who know how tack welding fits into the bigger fabrication picture. This means better surface finish and fewer adjustments down the line.

-

High Quality and Consistency

Our team follows best practices to deliver consistent tack welds that don’t compromise the final product. We focus on precision and durable welds that hold parts firmly in place during shipping and assembly.

-

Customized Solutions for Your Industry

Whether it’s automotive welding, shipbuilding welding, or other metal fabrication projects, we tailor tack welding methods to match the requirements and materials you need.

-

Problem Solving and Defect Prevention

Tack welding challenges like cracking or misalignment can slow down production. We proactively address these issues using techniques backed by industry insights, similar to the tips shared in our blog on preventing cracking in tack welds.

Choosing HYCNC means less downtime, better weld alignment, and a smoother path from CNC machining to final assembly. We bring precision and reliability to every tack weld, helping your project succeed from the ground up.

FAQs

What is tack welding used for?

Tack welding is mainly used to hold metal parts in place temporarily during CNC machining and metal fabrication. It ensures proper weld alignment before the final, permanent weld is done.

How is tack welding different from permanent welding?

Tack welding creates small, temporary welds. Permanent welding joins parts fully and is much stronger. Tack welds are just a first step to keep things steady.

Can tack welding be done with MIG and TIG welding?

Yes, both MIG welding and TIG welding can be used for tack welding. The choice depends on the metal type and precision required.

What industries rely on tack welding?

Industries like automotive welding, shipbuilding welding, and general metal fabrication make extensive use of tack welding during their CNC machining processes.

Are tack welds strong enough for heavy-duty use?

Tack welds are not designed for strength or durability. They’re temporary and usually removed or reinforced by permanent welds later.

How can HYCNC help with tack welding challenges?

At HYCNC, we focus on precision welding and proper weld joint preparation, reducing issues like poor fit-up or distortion to deliver high-quality tack welds for smooth CNC processing.

Is tack welding necessary for CNC machining?

Yes, tack welding plays a vital role in CNC machining by keeping parts aligned and stable, leading to better surface finish and accurate cuts.

If you have more questions about tack welding or need service, we’re here to help.