What Is Zinc Plating

Zinc plating is a popular metal finishing process where a thin layer of zinc is applied to a metal surface using electroplating. This process involves using an electric current to deposit zinc onto the part, creating a protective coating.

The key feature of zinc plating is its sacrificial coating property. Zinc acts as a barrier that protects the underlying metal from rust by corroding first. This gives excellent corrosion resistance at a relatively low cost, making zinc plating a cost-effective solution.

You’ll often find zinc plating used in industries like automotive, construction, and for fasteners such as screws and bolts. These applications benefit from zinc’s rust-preventing abilities without breaking the budget.

Advantages of Zinc Plating

- Low cost and easy to apply

- Excellent protection against rust and corrosion

- More environmentally friendly compared to some other plating methods

Limitations of Zinc Plating

- Not as tough under heavy wear or abrasion

- Less suitable for marine or highly corrosive saltwater environments

Zinc plating strikes a great balance for projects needing reliable corrosion protection without a high price tag, especially when wear resistance is not the main concern.

What Is Nickel Plating

Nickel plating is a metal finishing process where a thin layer of nickel is applied to a substrate, usually through electroplating or electroless nickel plating. Electroplating uses electric current to deposit the nickel coating, while electroless plating relies on a chemical reaction without electricity, offering more uniform coverage on complex shapes.

Key properties of nickel plating include:

- Hardness: Provides a tough, wear-resistant surface that holds up well under stress.

- Wear resistance: Ideal for parts that face constant friction or mechanical wear.

- Aesthetic appeal: Offers a bright, attractive finish that can range from satin to mirror-like.

Nickel plating is common in industries like aerospace, electronics, and decorative finishes where durability and appearance matter.

Advantages of nickel plating:

- Superior durability compared to many other coatings.

- Bright, premium finish that resists tarnishing.

- High electrical conductivity, useful in specialized electronic components.

Limitations to keep in mind:

- Nickel plating tends to be more expensive due to material and process costs.

- There are environmental concerns because of waste disposal regulations.

- Some people may experience allergic reactions to nickel, which limits its use in certain consumer products.

For businesses looking for nickel plating services, especially for industries like aerospace or electronics, understanding these factors will help make the right choice. If you want to explore our specialized nickel plating options, check out our nickel plating services.

Zinc Plating vs Nickel Plating Head-to-Head Comparison

When comparing zinc plating vs nickel plating, several key factors come into play, helping you pick the best finish for your project.

Corrosion Resistance

- Zinc plating offers sacrificial protection, meaning it corrodes first to protect the base metal. It performs exceptionally well in harsh, outdoor, and industrial environments.

- Nickel plating forms a strong barrier that resists corrosion but isn’t as effective as zinc in extreme or highly corrosive conditions.

Durability and Wear Resistance

- Zinc is softer and less resistant to abrasion, so it’s not the best choice for parts exposed to heavy wear.

- Nickel is much harder and better suited for high-wear applications, lasting longer under constant friction.

Cost and Energy Efficiency

- Zinc plating is more cost-effective and uses less energy during the electroplating process, making it a budget-friendly option.

- Nickel plating tends to be pricier due to more expensive materials and a more complex plating process.

Aesthetics and Finish

- Zinc provides a bright, reflective finish that’s functional and appealing for many industrial parts.

- Nickel offers a satin or mirror-like finish that gives a premium, polished look favored in decorative and high-end applications.

Environmental Impact

- Zinc plating is generally more eco-friendly and recyclable with fewer environmental restrictions.

- Nickel plating involves hazardous waste, leading to stricter regulations and environmental concerns.

Applications and Industry Suitability

- Zinc plating is popular in automotive, construction, and electrical components thanks to its corrosion protection and cost-effectiveness.

- Nickel plating is preferred in aerospace, electronics, and medical devices where durability and a refined finish matter most.

Choosing the Right Plating for Your CNC Project

Picking the right plating for your CNC parts depends on a few important factors: environment, budget, durability, and how the finished piece should look.

Consider These Factors:

- Environment: Will the part face harsh weather, moisture, or chemicals? Zinc plating is great for corrosion resistance in less extreme conditions. Nickel plating works better where wear and tear are heavy.

- Budget: Zinc plating is more cost-effective, a solid choice for projects where price matters. Nickel plating costs more but offers longer life and a higher-end finish.

- Durability Needs: If your parts need strong abrasion and wear resistance, nickel plating is the better option. Zinc plating suits lighter-duty uses.

- Aesthetics: Zinc offers a bright, shiny finish. Nickel plating can give you a satin or mirror-like look, perfect for premium or decorative parts.

When to Choose Zinc Plating:

- Projects focused on corrosion resistance

- Tight budgets or large volume runs

- Automotive, construction, or fastener parts

When to Choose Nickel Plating:

- High-wear parts requiring durability

- Premium finishes for electronics, aerospace, or decorative uses

- When electrical conductivity is needed

At HYCNC, we provide customized plating solutions for both zinc and nickel. Our expertise ensures your CNC parts meet the exact demands of your project and industry, balancing cost, durability, and appearance to get the job done right.

Advanced Options Zinc-Nickel Alloy Plating

Zinc-nickel alloy plating combines the best of both metals into one hybrid coating. This mix creates a layer that offers stronger corrosion resistance than zinc alone, making it ideal for tough environments. It also brings improved durability and better heat resistance, which helps parts last longer under stress.

This plating solution is widely used in automotive, aerospace, and oil and gas industries, where parts need to withstand harsh conditions without sacrificing performance or safety. At HYCNC, we recommend zinc-nickel alloy plating for high-performance CNC parts that demand extra protection and reliability.

If you want a plating option that balances cost, durability, and corrosion protection, zinc-nickel alloy is a smart choice for your project.

How HYCNC Ensures Quality Plating for CNC Parts

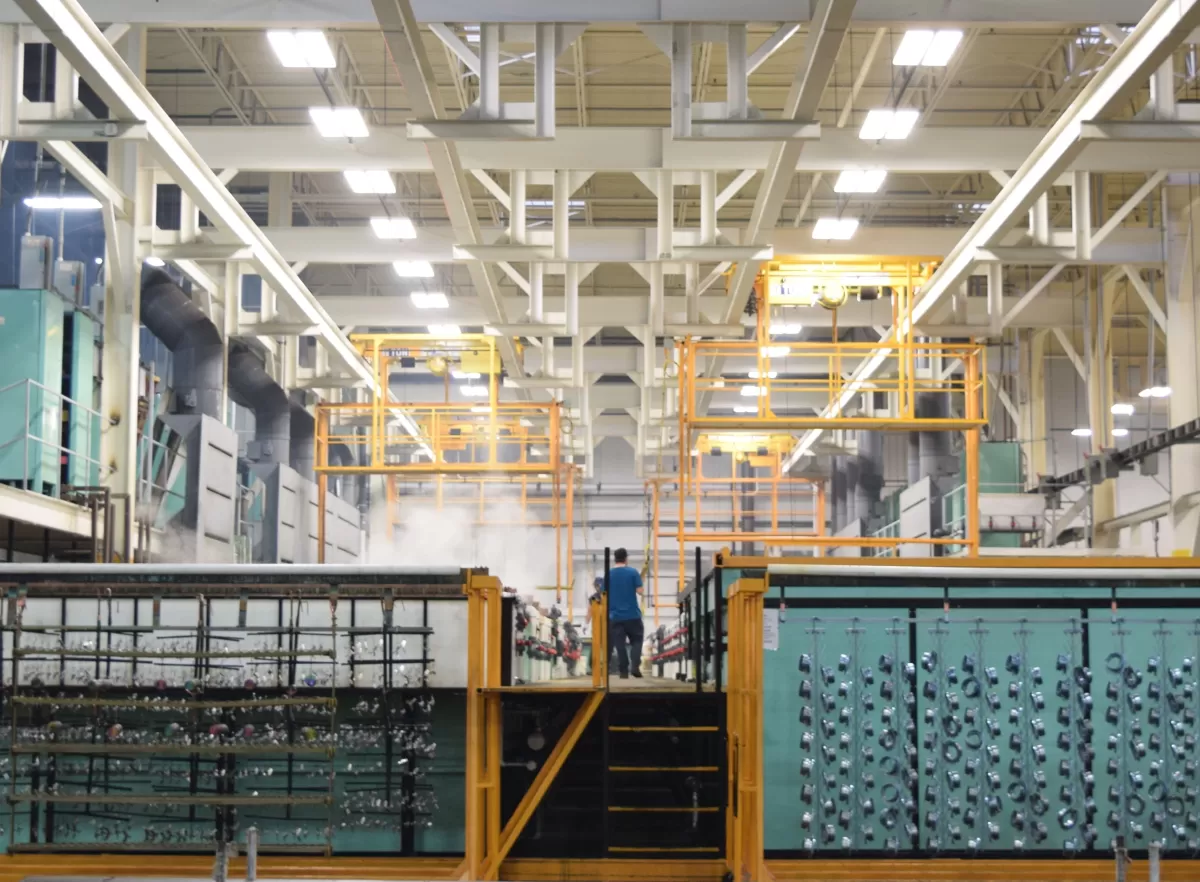

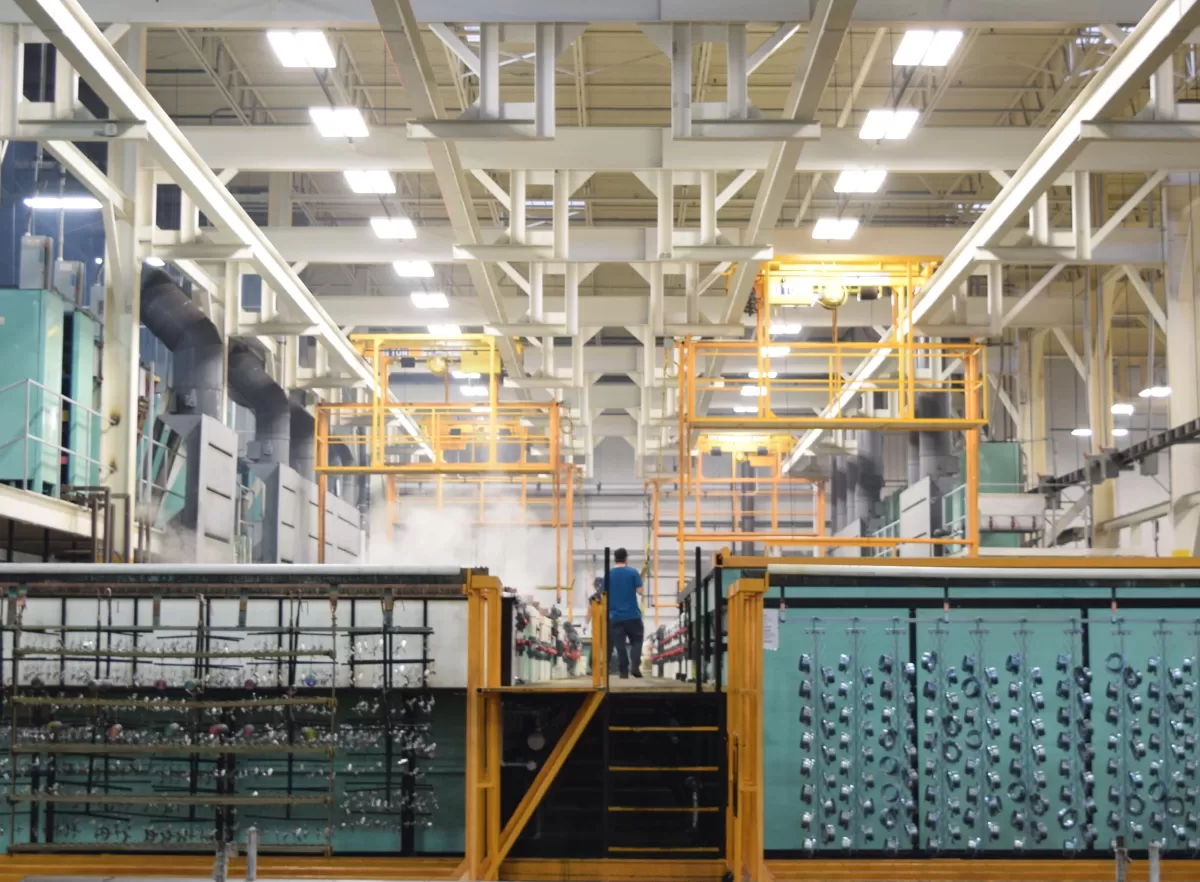

At HYCNC, we take quality plating seriously. Our state-of-the-art electroplating facilities use the latest technology to ensure every CNC part gets a consistent, durable finish. We don’t do one-size-fits-all plating — instead, we create customized solutions tailored to the unique needs of each industry we serve. Whether it’s automotive, aerospace, or electronics, we adjust our processes to meet exact standards.

We’re also committed to sustainability. Our plating methods comply with all environmental regulations, minimizing waste and reducing hazardous byproducts. This approach helps us deliver eco-friendly plating solutions without compromising quality.

A recent project involved plating high-wear aerospace components with zinc-nickel alloy. By applying our customized plating process, we boosted corrosion resistance and durability, exceeding the client’s expectations. This success story highlights how HYCNC blends advanced technology and expert know-how to deliver top-quality CNC plating every time.

FAQs about Zinc Plating vs Nickel Plating

What is the main difference between zinc and nickel plating?

Zinc plating offers sacrificial corrosion protection, making it great for harsh environments, while nickel plating provides a harder, more wear-resistant finish with a premium look.

Which plating is more cost-effective for CNC parts?

Zinc plating is generally more affordable and requires less energy, making it ideal for budget-focused projects. Nickel plating costs more due to materials and a more complex process.

Can zinc and nickel plating be used together?

Yes, zinc-nickel alloy plating combines the best of both—improved corrosion resistance and durability. It’s a popular choice for high-performance CNC parts.

How does HYCNC ensure the quality of its plating processes?

HYCNC uses advanced electroplating equipment, customizes solutions to your industry needs, and follows strict environmental and safety standards to deliver consistent, top-quality finishes.

What industries benefit most from zinc vs nickel plating?

Zinc plating is common in automotive, construction, and fasteners. Nickel plating suits aerospace, electronics, and decorative applications needing extra durability and a refined finish.