What is Annealed Metal

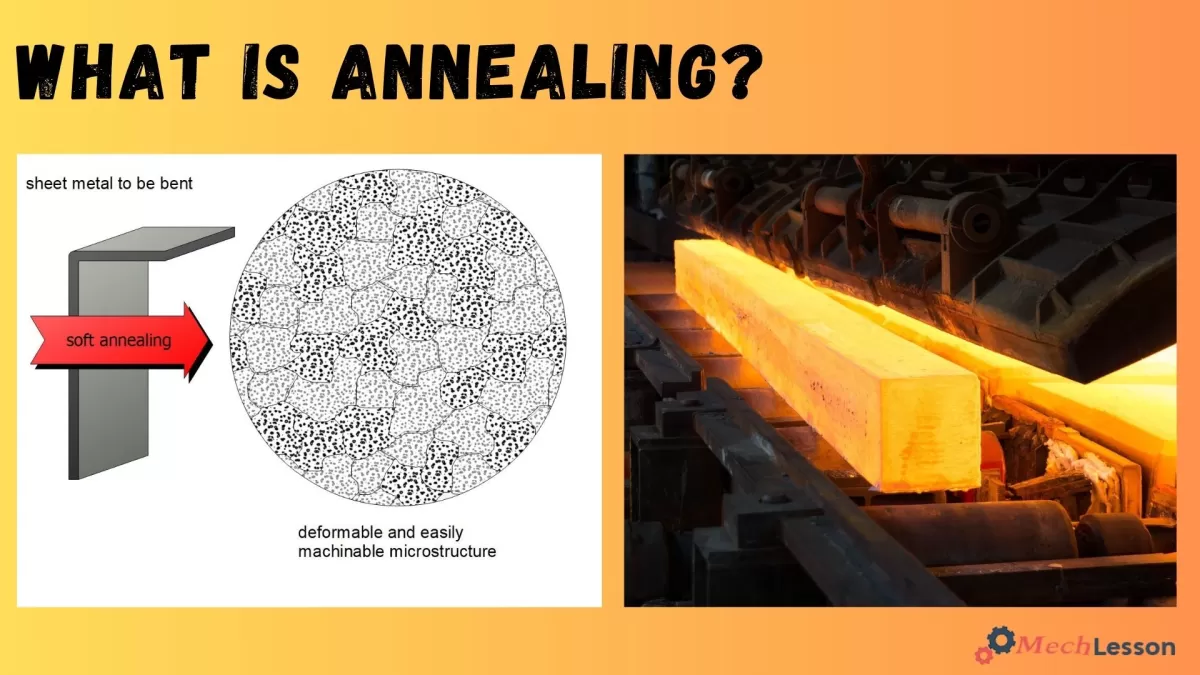

Annealed metal is metal that has undergone a heat treatment process called annealing to improve its properties. During annealing, the metal is heated to a specific temperature and then cooled slowly. This process changes the metal’s microstructure, making it softer, more ductile, and easier to work with.

At the microscopic level, annealing reduces internal stresses and allows new, strain-free grains to form. This transformation refines the metal’s grain structure, which directly affects its strength, hardness, and flexibility.

Common metals that are annealed include steel, copper, aluminum, and brass. These metals benefit from annealing in different ways, such as improved machinability or enhanced formability.

Compared to non-annealed metal, annealed metal is less brittle and more pliable. Non-annealed metal tends to be harder and stronger but can crack or break under stress. Annealed metal balances strength with flexibility, making it ideal for various manufacturing processes like CNC machining.

The Annealing Process How It Works

Annealing is a heat treatment that changes how metal behaves by heating it and then cooling it carefully. The process has a few key stages:

-

Recovery Stage: When the metal is heated, internal stresses caused by previous work like bending or shaping start to ease. This stage helps relieve those stresses without changing the metal’s overall structure.

-

Recrystallization Stage: As the temperature rises, new grains begin to form inside the metal. These new grains replace the old, deformed ones, making the metal softer and more ductile. This stage is essential for restoring the metal’s workability.

-

Grain Growth: If the temperature continues to stay high for a while, these new grains can grow larger. Managing this grain growth is important because it affects the metal’s strength and flexibility.

-

Controlled Cooling: After heating, the metal is cooled slowly, often in air or a furnace. This slow cooling keeps the metal soft and keeps unwanted stresses from building up again.

Typical annealing happens between 650°F and 1300°F, depending on the metal type. Cooling methods vary between slow furnace cooling and air cooling, depending on the desired final properties.

By carefully managing these steps, annealed metal gains improved ductility and less hardness, making it ideal for further machining or forming.

Types of Annealing

Annealing comes in several types, each serving a specific purpose depending on the metal’s condition and what you need from it.

-

Full Annealing: This method heats the metal to a high temperature and then cools it slowly. The goal is to make the metal as soft and ductile as possible, improving workability for shaping and machining.

-

Process Annealing: Used mainly for metals that are cold-worked or slightly hardened, process annealing restores ductility without fully softening the metal. It helps metals stay tough but easier to bend or form.

-

Stress Relief Annealing: After casting, welding, or heavy machining, metals can have internal stresses that cause warping or cracking later. Stress relief annealing gently heats the metal just enough to reduce these stresses without changing the metal’s overall hardness.

-

Recrystallization Annealing: This targets cold-worked metals, heating them to a temperature that allows new grain structures to form. This refreshes the metal’s microstructure, making it softer and more ductile for further processing.

Each annealing type plays a key role in preparing metals for different manufacturing steps, helping improve metal workability and CNC machining results.

Benefits of Annealed Metal

Annealed metal offers several advantages that make it a top choice for many manufacturing processes, especially CNC machining. Here’s why it stands out:

-

Enhanced ductility for shaping and bending

Annealing makes metal softer and more flexible, which means it can be easily shaped, bent, or formed without cracking. This is crucial when working on complex parts or intricate designs.

-

Reduced hardness improves machinability

Softer annealed metal is easier to cut, drill, or mill. This reduces tool wear and speeds up machining, saving time and costs.

-

Stress relief prevents cracking and distortion

The annealing process removes internal stresses caused by previous work like casting or welding. This lowers the risk of cracks and warping during further processing or use.

-

Improved conductivity and corrosion resistance

Annealed metals often have a cleaner, more consistent microstructure which can improve electrical conductivity and help resist corrosion in certain environments.

-

Cost-effectiveness in manufacturing

By reducing tool wear, lowering scrap rates, and improving product quality, annealed metal helps keep production costs down. It’s a smart choice for both small jobs and large-scale projects.

These benefits make annealed metal a reliable and efficient option for companies looking for quality, precision, and durability in their metal parts.

Applications of Annealed Metal in CNC Machining

Annealed metal is a top choice for CNC machining because of its improved softness and ductility. When metals are annealed, they become easier to shape and cut with precision tools, making them perfect for detailed and complex parts. This increased workability reduces tool wear and results in better surface finishes, which is crucial for high-precision manufacturing.

In industries like automotive, aerospace, and electronics, annealed metal is widely used to create components that need to be both strong and finely detailed. For example:

- Automotive: Engine parts, brackets, and connectors that require tight tolerances and smooth finishes.

- Aerospace: Lightweight structural elements and precision fittings where metal fatigue resistance is critical.

- Electronics: Housings and connectors where accuracy and surface quality affect performance.

At HYCNC, we specifically use annealed metal for producing precision parts because it offers consistent machinability and reliable dimensional accuracy. Our advanced CNC machining equipment takes full advantage of annealed metal’s properties, ensuring each custom part meets strict quality standards for performance and durability.

For more insights on metal processing methods and precision part manufacturing, check out our what is investment casting article.

Annealed Metal vs Other Heat Treatments

When comparing annealed metal to other heat treatments like tempering, normalizing, and quenching, the differences come down to the metal’s final properties and best uses.

-

Annealing softens metal by heating it and then cooling slowly. This makes the metal more ductile and easier to machine, reducing hardness and internal stresses. It’s great for parts that need shaping or precision machining.

-

Tempering is used after quenching to reduce brittleness while keeping some hardness. It’s common when you need a balance of strength and toughness but less suitable if you want maximum softness.

-

Normalizing heats the metal and cools it in air to refine grain structure. It makes the metal tougher and stronger than annealed metal but still harder and less workable.

-

Quenching rapidly cools metal to lock in high hardness but leaves it brittle and prone to cracking without further treatment.

| Heat Treatment | Hardness | Ductility | Internal Stress | Common Use |

|---|---|---|---|---|

| Annealing | Low | High | Low | CNC machining, forming |

| Tempering | Medium | Medium | Medium | Tools, structural parts |

| Normalizing | Medium-High | Medium | Medium | Forgings, castings |

| Quenching | High | Low | High | Wear-resistant parts |

Why annealing is preferred for CNC machining

Annealed metal offers a perfect balance for CNC machining:

- Easier to cut and shape without tool damage

- Reduced risk of cracking or warping during machining

- Better surface finish and dimensional accuracy

- Consistent material behavior under CNC tools

For USA manufacturers needing reliable, machinable metal, annealing ensures parts come out precise and cost-effective without sacrificing quality.

Why Choose HYCNC for Annealed Metal Processing

When it comes to annealed metal processing, HYCNC stands out for a few key reasons. First, our team has deep expertise in handling annealed metals, ensuring your parts meet exact specifications. We use advanced CNC equipment that delivers consistent precision while maintaining the metal’s improved ductility and machinability after annealing.

Quality control is a top priority at HYCNC. Every project undergoes thorough inspection to prevent defects like cracking or distortion, which can happen if annealed metal isn’t handled properly. Our experience with various metals and annealing types means we can recommend the best approach for your specific CNC machining needs.

If you need custom CNC parts made from annealed metal, HYCNC offers a reliable and cost-effective solution. Get in touch today to learn how we can help bring your project from concept to reality with precision and quality you can trust.

FAQs About Annealed Metal

What metals are suitable for annealing

Common metals like steel, copper, aluminum, and brass respond well to annealing. These metals benefit from improved ductility and reduced hardness after the annealing process, making them easier to shape and machine.

How does annealed metal impact CNC machining

Annealed metal is softer and less brittle, which means CNC machines can cut and shape it more precisely without tool wear or cracking. This improves surface finish and extends tool life during machining.

What is the difference between annealing and normalizing

Annealing heats metal above its critical temperature followed by slow cooling to soften and relieve stress. Normalizing, on the other hand, cools the metal faster (usually in air) to refine grain size but keeps the metal harder than annealed metal.

Can annealed metal be re-hardened

Yes. After annealing and machining, metals like steel can be re-hardened by heat treating or quenching if higher strength or hardness is needed.

Why is slow cooling important in annealing

Slow cooling prevents the formation of unwanted stresses and allows new, uniform grain structures to form. This results in metal that is more ductile and free of cracks, which is key for good machinability and part performance.