Are you looking to optimize your industrial machinery with custom spline shafts? In the world of heavy-duty applications, choosing the right components can make or break your equipment’s performance. As an industry professional, I understand the critical role precision spline shafts play in ensuring reliability and efficiency. Drawing from real-world expertise, this guide dives into why custom spline shafts are essential for industrial success, from heavy machinery to robotics. Whether you’re an engineer or a procurement manager, you’ll discover how tailored solutions from HYCNC can power your operations. Let’s explore the importance of custom spline shafts and why they’re a game-changer for your industry!

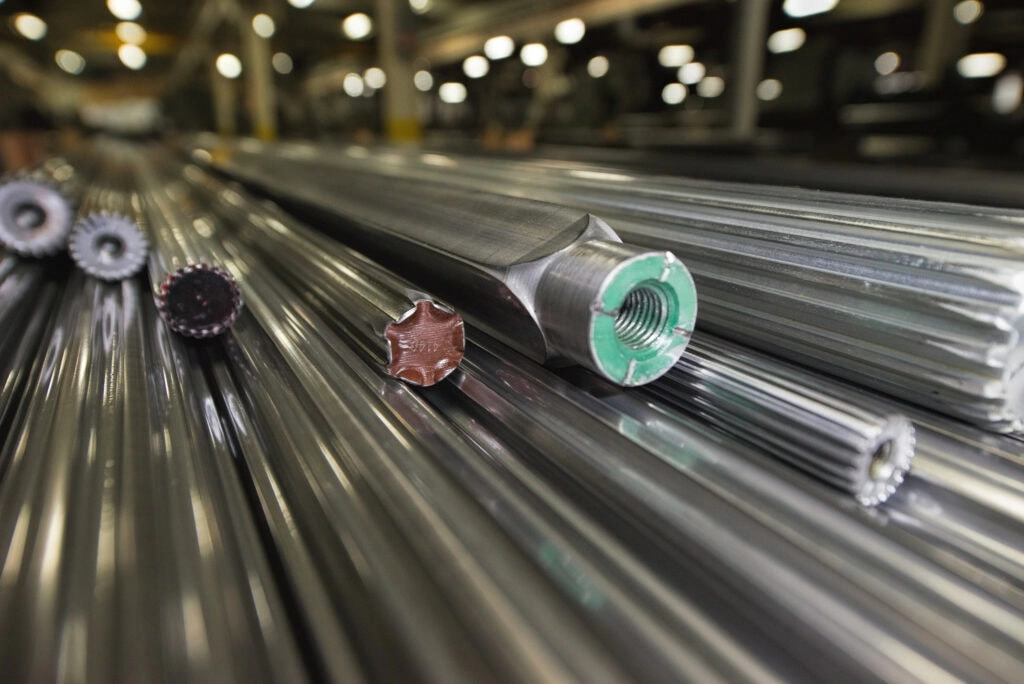

What Are Custom Spline Shafts Definition Types and Customization Aspects

Custom spline shafts are specially designed mechanical components used to transmit torque between mating parts in various industrial applications. Unlike standard spline shafts, custom spline shafts are tailored to meet specific requirements related to size, shape, material, and performance, ensuring optimal fit and function.

Understanding Spline Shaft Basics

A spline shaft features a series of ridges or teeth—commonly following an involute spline design—which mesh precisely with grooves in mating components. This connection allows for efficient industrial torque transmission while maintaining axial alignment. The shaft’s design can significantly impact precision spline shafts’ performance in demanding environments.

Types of Custom Spline Shafts

Customization in spline shaft manufacturing covers a wide range of types based on geometry and application, including:

- Parallel Key Spline Shafts: Offer simple straight-sided grooves for moderate torque applications.

- Involute Spline Shafts: Most common type with curved tooth profiles for smooth torque transfer and high precision.

- Ball Spline Shafts: Incorporate ball bearings for combined torque transmission and linear motion.

- Full and Partial Spline Shafts: Customized based on whether the spline extends across the entire shaft length or partially.

Customization Aspects in Spline Shaft Manufacturing

Customization is critical in meeting the unique demands of heavy machinery, automotive, aerospace, and other sectors. Key customization factors include:

- Material Selection: From alloy steels to stainless steel or specialty materials, choosing the right spline shaft materials optimizes strength and durability.

- Dimensional Specifications: Tailoring shaft diameter, length, and spline tooth count to fit mating parts precisely.

- Surface Finish and Treatment: Enhancing wear resistance and fatigue life through heat treatment, coating, or specialized surface finishes.

- Performance Requirements: Adjusting design for load capacity, torque range, and operating environment for reliable and efficient function.

- Integration with CNC Machining Services: Leveraging custom CNC machining for tight tolerances and consistent quality on complex spline profiles.

By focusing on these elements, custom spline shafts support high-performance, reliable operation in demanding industrial environments, surpassing standard alternatives in both functionality and longevity.

Key Industrial Applications of Custom Spline Shafts

Custom spline shafts play a critical role across various industries because they are designed to meet specific performance and durability needs. Their precision spline shafts and involute spline design make them ideal for transmitting torque accurately even under demanding conditions. Here’s a closer look at the main sectors using custom spline shafts:

Heavy Machinery

In heavy machinery, custom spline shafts are essential for industrial torque transmission. These components handle high loads and intense stress in equipment like construction gear, mining machines, and agricultural tools. Custom shafts are often tailored for strength and wear resistance to ensure longevity and reliable operation in tough environments.

Automotive and Transportation

The automotive industry relies heavily on automotive spline shafts customized to fit unique drivetrain and transmission needs. Properly designed spline shafts contribute to smoother power transfer between engine and wheels, improving vehicle efficiency and performance. Transportation sectors like rail and commercial vehicles also benefit from custom shafts designed for specific torque and speed requirements.

Robotics

Robotics demands precision spline shafts with tight tolerances to ensure precise movements. Custom spline shafts in robots help deliver accurate torque in joints and actuators, supporting smooth operation and flexibility. Given the precision needed, these components are often manufactured using advanced custom CNC machining techniques to ensure the highest quality.

Aerospace

In aerospace, the emphasis is on lightweight yet durable components. Custom spline shafts here must meet strict standards for strength, precision, and reliability. They are used in various aircraft systems to transmit power efficiently while minimizing weight — a balance that’s vital for flight safety and performance.

Using custom spline shafts tailored to specific applications ensures high-performance splines capable of withstanding the unique demands of each industry. Whether it’s enhanced durability for heavy machinery or pinpoint accuracy in robotics, customization through expert spline shaft manufacturing and CNC machining services is key to achieving optimal results.

Benefits of Custom Spline Shafts in Industrial Applications

When it comes to industrial torque transmission, custom spline shafts offer clear advantages over standard options. Here’s why investing in custom CNC machining for spline shafts pays off:

Enhanced Performance and Precision

Custom spline shafts are designed to fit your exact needs. This means:

- Precise torque transfer with minimal backlash, improving machine efficiency.

- Tailored involute spline design for smooth, reliable operation.

- Better alignment with mating components reduces wear and extends equipment life.

Improved Reliability and Durability

With materials and dimensions chosen specifically for your application, custom spline shafts can handle:

- Higher loads common in heavy machinery components and automotive spline shafts.

- Varying environmental conditions like heat, dust, or moisture that off-the-shelf parts might not withstand.

- More consistent performance, reducing downtime and unexpected failures.

Material Optimization

Custom CNC machining allows you to select the right spline shaft materials that deliver:

- The perfect balance of strength and weight.

- Enhanced resistance to corrosion or fatigue.

- Cost savings by avoiding over-specification without sacrificing quality.

Cost Efficiency Over Time

While custom spline shafts may have a higher upfront cost, they save money by:

- Reducing maintenance and replacement needs.

- Lowering energy consumption thanks to better fit and function.

- Minimizing production delays caused by component failure.

Flexibility for Unique Needs

Custom spline shafts can be tailored to unique or complex designs, which means:

- Ability to meet specific industrial requirements across sectors like aerospace, robotics, or transportation.

- Incorporating unusual sizes, keyways, or surface finishes that standard parts can’t offer.

- Easier integration into existing systems, reducing modification costs.

custom spline shafts from reliable CNC machining services like TopCNCPro deliver tangible benefits in precision spline shafts performance, durability, and cost-effectiveness. Tailoring each shaft to the application ensures you get the right part the first time—supporting smoother, more efficient industrial operations.

Why Choose Custom Over Standard Spline Shafts

When it comes to spline shaft manufacturing, opting for custom spline shafts instead of standard ones can make a significant difference in your project’s success. Here’s why custom options often outperform off-the-shelf spline shafts, especially in demanding industrial environments.

Tailored Fit for Specific Applications

Custom spline shafts are designed to match your unique machine requirements. Unlike standard spline shafts, which come with generic sizes and profiles, custom shafts ensure perfect alignment and fit, reducing wear and tear.

Benefits include:

- Accurate involute spline design tailored to your torque transmission needs

- Better compatibility with mating components

- Reduced risk of mechanical failure

Superior Performance and Reliability

Because custom spline shafts are made with precision and exact specifications, they deliver enhanced performance and higher reliability. They’re less prone to slipping or backlash, which is critical in applications like heavy machinery or aerospace.

Material and Design Flexibility

Custom options give you control over key factors like:

- Spline shaft materials suited for your environment (corrosion resistance, strength)

- Specific tooth profiles and lengths for optimized torque handling

- Surface treatments to improve durability

This flexibility is rarely available with standard spline shafts.

Cost-Efficiency in the Long Run

Although custom spline shafts might seem more expensive upfront, they often save money over time through:

- Lower maintenance and downtime

- Longer part life and improved machine efficiency

- Reduced need for frequent replacements

Meeting Industry Standards and Compliance

Custom spline shafts are typically produced using advanced CNC machining techniques, ensuring they meet strict industry standards. This is essential for sectors like automotive and aerospace, where compliance can’t be compromised.

In , choosing custom over standard spline shafts means investing in a solution that’s built to perform, fit, and last exactly as your industrial application demands. This translates into improved torque transmission, better machine efficiency, and overall lower total cost of ownership.

The Role of Advanced CNC Machining in Custom Spline Shafts

When it comes to custom spline shaft manufacturing, advanced CNC machining plays a vital role in delivering precision, quality, and reliability. The accuracy of the spline teeth, the shaft’s overall dimensions, and surface finish directly impact the shaft’s performance in demanding industrial torque transmission applications.

Precision CNC Capabilities

Modern CNC machining services use computerized controls to produce spline shafts with extremely tight tolerances. This precision is essential for ensuring that the shaft fits perfectly with mating parts, reducing wear and improving lifespan. Whether it’s an involute spline design or custom tooth profiles, CNC machines can handle complex geometries that manual methods simply can’t replicate consistently.

Superior Surface Finish

A smooth surface finish on spline shafts is more than just aesthetic—it reduces friction and minimizes fatigue during operation. Advanced CNC equipment provides consistent surface finishes that help maintain precision spline shafts‘ durability and performance under heavy loads typical in heavy machinery components and automotive spline shafts.

Adhering to Standards and Quality Compliance

Custom spline shafts often must meet strict industry standards for safety and performance. CNC machining helps manufacturers comply with these standards by maintaining consistent product quality and repeatability. This ensures the finished spline shafts work reliably in critical sectors like aerospace and robotics where failure is not an option.

Benefits of Using CNC for Custom Spline Shafts

- High repeatability ensures every shaft meets exact specifications.

- Flexible customization for various materials and spline profiles.

- Efficient production reduces lead times in custom orders.

- Enhanced quality control through real-time monitoring and precision tools.

In short, relying on custom CNC machining is key to producing high-performance splines that meet the varied demands of industrial clients across the United States, delivering shafts that perform flawlessly in real-world conditions.

How to Choose a Reliable Custom Spline Shaft Provider

Picking the right custom spline shaft manufacturing partner is critical for getting high-quality, durable shafts that fit your specific industrial needs. Here’s what I focus on when choosing a provider for precision spline shafts and custom CNC machining services.

Look for Expertise in Spline Shaft Manufacturing

A good supplier has a strong track record in involute spline design and understands the unique demands of industrial torque transmission. Make sure they have experience with your industry, whether it’s heavy machinery components, automotive spline shafts, or aerospace applications. Knowledge of different spline shaft materials and their performance in various conditions is a must.

Check Their CNC Machining Capabilities

Advanced CNC machining is key for precision and reliability. Confirm the provider uses state-of-the-art CNC machining services and equipment, like CNC routers or milling machines, capable of consistent tight tolerances and superior surface finishes. This ensures the splines will fit perfectly and perform well without early wear or failure.

Verify Quality Standards and Certifications

Reliable manufacturers follow strict quality controls and are often certified to ISO or other industry standards. Ask about their testing processes, like hardness testing or dimensional inspection, which are critical to guaranteeing high-performance splines. Consistent quality means fewer headaches down the line.

Material and Customization Flexibility

A top provider offers a range of materials suited for different load and environmental conditions – from high-strength steel to specialty alloys. They should be willing and able to customize every aspect from shaft length to spline count, ensuring the product matches your exact specifications and application.

Responsive Communication and Support

Good communication is essential. Look for a partner who listens to your needs, offers design advice, and provides clear timelines. Fast, transparent responses help avoid delays and ensure your custom spline shafts meet your deadlines and budget.

Consider Local Providers with Industry Experience

Choosing a supplier based in the United States can be beneficial for quicker shipping, easier communication, and better support tailored to local industrial standards. Providers like TopCNCPro specialize in CNC machining services for the U.S. market, providing high-quality customized splines that match exact industry requirements.

of Key Selection Criteria

- Expertise in spline shaft manufacturing and design

- Advanced CNC machining capabilities

- Strict quality control and industry certifications

- Wide material selection and customization options

- Responsive communication and project support

- Local presence and experience with U.S. industrial needs

Taking the time to vet your custom spline shaft provider against these points ensures you get reliable, cost-effective, and high-performance shafts suited for your industrial application.