What Are Custom Sheet Metal Brackets Definition Types and Customization Needs

Custom sheet metal brackets are precision-engineered components designed to provide support, mounting, or structural integrity in various applications. Unlike standard brackets, these are tailored specifically to meet unique project requirements in terms of size, shape, material, and functionality.

Understanding Custom Sheet Metal Brackets

At their core, these brackets are fabricated from sheet metal such as stainless steel, aluminum, or galvanized steel using advanced techniques like CNC laser cutting, bending, and welding. The goal is to create brackets that fit perfectly, align with specific load capacities, and integrate seamlessly into different assemblies or structures.

Common Types of Sheet Metal Brackets

Custom brackets come in diverse forms depending on their application, including:

- L-brackets for right-angle support

- U-brackets for holding cylindrical objects or frames

- Channel brackets designed to guide cables or components

- Flanged brackets for enhanced mounting strength

- Adjustable brackets that allow flexibility in positioning

Each type serves distinct industrial or commercial purposes, from mounting heavy equipment to supporting delicate electronics.

Why Customization Matters in Sheet Metal Brackets

Customization addresses challenges that off-the-shelf brackets often cannot:

- Precise fit to existing machinery or installation sites

- Material choice aligned with strength, corrosion resistance, or weight considerations

- Specific hole patterns or mounting features designed for unique fasteners

- Surface finishes to match aesthetic or functional needs, including powder coating or plating

- Complex geometries enabled by advanced CNC fabrication to meet detailed engineering specifications

These factors are critical for industries relying on industrial bracket applications, where standard solutions may compromise safety, durability, or performance.

Meeting Your Project Needs with Custom Fabrication

Every project has distinct criteria based on industry demands or operational environments. Custom sheet metal components help you:

- Achieve unmatched structural integrity

- Ensure compatibility with existing equipment or infrastructure

- Optimize material use to control cost without sacrificing quality

- Adapt quickly to design changes and production timelines

By choosing a specialized service like HYCNC for custom sheet metal bracket fabrication, you get expert guidance on materials, design-for-manufacturability, and cutting-edge CNC processing—ensuring your brackets are not just parts, but reliable solutions tailored to your goals.

The Custom Sheet Metal Bracket Fabrication Process

Overview of Custom Sheet Metal Bracket Fabrication

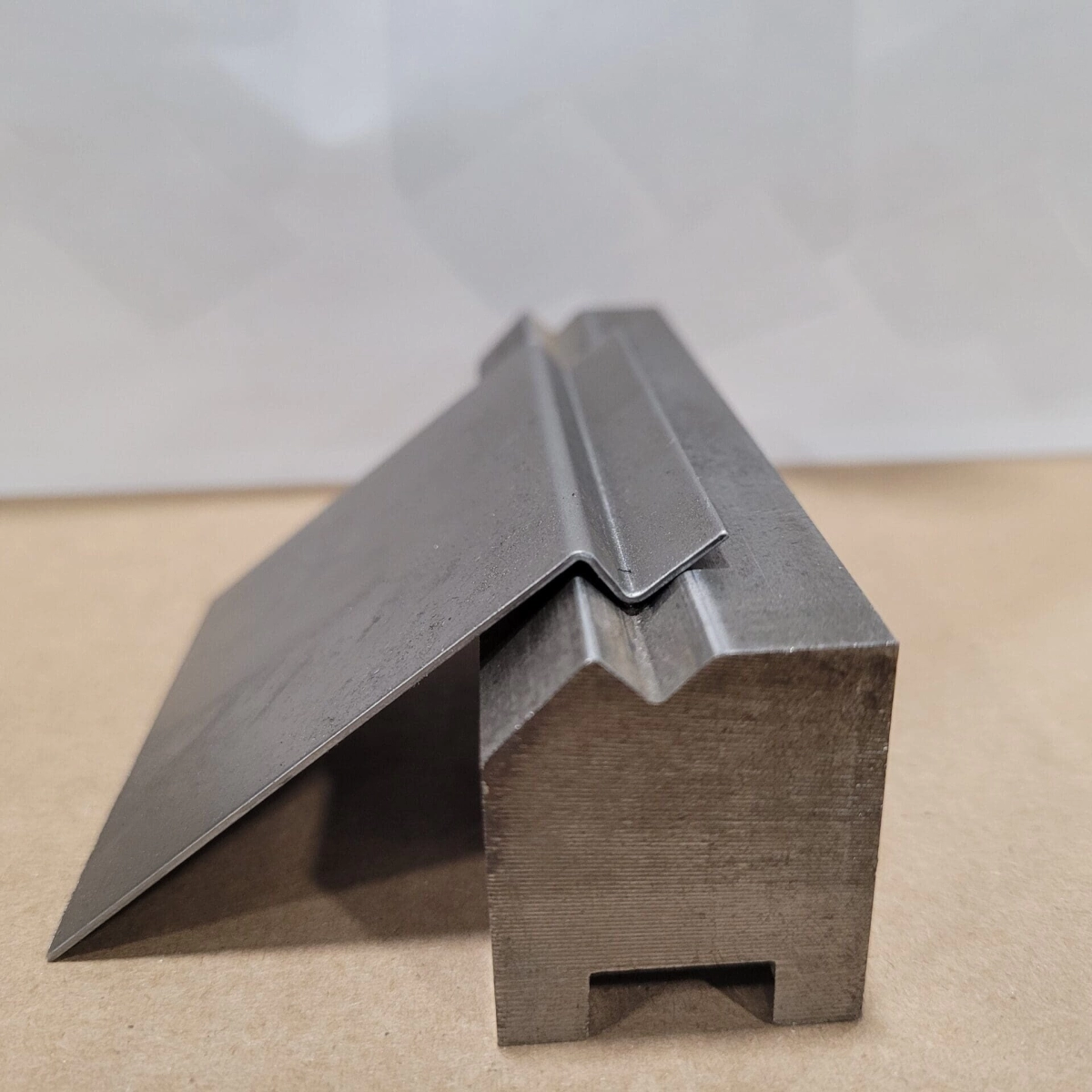

Custom sheet metal bracket fabrication is a detailed process that turns your design specifications into durable, precise brackets. At its core, it involves cutting, bending, and assembling sheet metal to create parts that perfectly fit your application. Whether you need simple L-brackets or complex industrial brackets, the process prioritizes precision CNC bracket fabrication and material efficiency to meet custom requirements.

HYCNC Approach to Sheet Metal Bracket Fabrication

At HYCNC, we combine advanced CNC laser cutting brackets technology with expert sheet metal bending techniques to deliver consistent quality. Our approach focuses on:

- Design for manufacturability: We make sure your design is optimized for efficient cutting and bending, reducing waste and production time.

- Material selection: From stainless steel bracket manufacturing to aluminum and other custom sheet metal components, we select the right metal for strength, corrosion resistance, and cost.

- Precision CNC services: Using top-tier CNC routers and laser cutters, we achieve tight tolerances and clean edges on every bracket.

- Assembly readiness: We factor in how brackets will be joined or installed, often suggesting alternatives to welding for joining laser-cut metal to streamline assembly.

Learn more about designing for production with detailed insights in our post on sheet metal design for manufacturability.

Key Considerations in the Fabrication Process

When fabricating custom brackets, several factors are crucial to ensure your parts perform well:

- Material thickness and type: This affects flexibility, welding options, and final strength.

- Bending radius and tolerances: Proper bending avoids cracks and deformation during the sheet metal bending process.

- Surface finish and protection: Depending on the application, surface treatments may be required to prevent corrosion or improve aesthetics—check our guide on sheet metal surface finish options.

- Production lead times: Efficient workflow at HYCNC keeps turnaround times short without sacrificing quality, key for tight project timelines.

- Cost efficiency: Using precision CNC fabrication helps reduce scrap and rework, providing budget-friendly custom metal fabrication services.

Choosing HYCNC means you’re working with a provider who understands these nuances and uses local expertise to deliver exactly what you need. You can also work with top metal bracket manufacturers like TopCNCPro who have been dedicated to metal bracket fabrication for many years! Our knowledge of industrial bracket applications ensures the best approach whether you need a handful of parts or full production runs.

For a deeper dive into metal fabrication methods, see our metal fabrication technology overview.

This process overview outlines how HYCNC’s custom CNC solutions ensure your sheet metal brackets are made right the first time with precision, speed, and cost-effectiveness.

Benefits of Choosing Custom Sheet Metal Bracket Fabrication with HYCNC

When it comes to custom sheet metal bracket fabrication, working with HYCNC has distinct advantages that elevate your project from start to finish. Here’s why our custom metal fabrication services stand out in the US market:

Precision and Perfect Fit

At HYCNC, we use precision CNC bracket fabrication techniques, including CNC laser cutting brackets and advanced bending methods, to ensure each bracket fits your exact specifications. This precise fit reduces installation errors and enhances the overall performance of your assembly or equipment. Our process guarantees tight tolerances, so your custom sheet metal components work seamlessly without extra adjustments.

Material Versatility for Every Need

We understand different projects demand different materials. Whether you need stainless steel bracket manufacturing for durability, aluminum for lightweight applications, or other metals, HYCNC supports a wide range of materials. This versatility allows you to choose the best option for strength, corrosion resistance, or cost efficiency without compromising on quality. Our expertise in sheet metal bending techniques ensures your chosen material performs well throughout the fabrication process.

Fast Turnaround Time

Thanks to our streamlined process and in-house CNC capabilities, HYCNC can deliver your custom brackets faster than many competitors. We prioritize quick cycles without cutting corners. This fast turnaround supports your tight project schedules, helping avoid costly delays and keeping production on track.

Cost Efficiency Without Sacrificing Quality

Custom fabrication is often seen as expensive, but HYCNC works to offer cost-effective custom sheet metal components optimized for manufacturability. Through careful design consultation and efficient use of materials, we minimize waste and reduce labor time. This ultimately lowers your total project cost while still delivering high-quality, reliable brackets.

Choosing HYCNC means you’re not just getting custom brackets—you’re getting precision, material options, speed, and savings all wrapped into one comprehensive custom CNC solution. For more insight into our processes, check out our blog on what is metal fabrication technology to understand how we leverage tech for superior results.

Design Tips for Optimal Custom Sheet Metal Bracket Fabrication

When designing custom sheet metal brackets, keeping manufacturability and function in mind from the start saves time and money. Here are best practices to ensure your brackets deliver precision and durability, while avoiding common pitfalls.

Focus on Sheet Metal Design for Manufacturability

- Plan for bending radii: Avoid sharp bends by incorporating appropriate bend radii based on your material thickness. This improves strength and reduces stress during sheet metal bending techniques.

- Keep holes and slots practical: Position holes and cutouts so they don’t interfere with bends or edges. Use standard hole sizes compatible with CNC laser cutting brackets.

- Design for standard material gauges: Use common stainless steel bracket manufacturing gauges to minimize waste and cost.

- Consider assembly: If your bracket needs to connect with other components, leave proper clearances and incorporate tabs or slots for easy, secure assembly.

Avoiding Common Design Pitfalls

- Overcomplicated shapes: Complex designs increase fabrication time and cost. Focus on simplicity where possible.

- Ignoring material properties: Different metals behave differently during bending and cutting. Make sure your design suits the material’s capabilities, whether it’s aluminum, stainless steel, or mild steel.

- Unrealistic tolerances: Tight tolerances add cost and may not be necessary. Specify tolerances only as tight as needed for your application.

How HYCNC Supports Your Design Process

- Expert design review: Our engineers review your custom sheet metal components to optimize sheet metal design for manufacturability and identify any potential issues early.

- Material advice: We help you select the right metal and thickness for your bracket needs.

- Feedback on fit and function: We provide suggestions to improve bracket precision CNC fabrication to ensure a perfect fit and performance.

By following these design tips and working closely with HYCNC’s custom CNC solutions team, you get strong, reliable brackets made right the first time—saving you time, money, and frustration.

Industries Served by HYCNC Custom Sheet Metal Bracket Fabrication

At HYCNC, our custom sheet metal bracket fabrication services cater to a wide range of industries. We understand each sector’s unique needs, which is why we deliver precision CNC bracket fabrication and custom sheet metal components designed for specific applications. Whether it’s small-batch projects or large industrial runs, our expertise ensures reliable, high-quality results every time.

Key Industries and Applications

- Industrial Manufacturing: Durable brackets for heavy machinery, conveyors, and structural supports that require strong sheet metal bending techniques and wear resistance.

- Automotive: Custom metal brackets for mounting, securing, and supporting components with tight tolerances and stainless steel bracket manufacturing options.

- Electrical and Electronics: Lightweight, precise brackets used in enclosures, racks, and mounting systems that require clean edges from CNC laser cutting brackets.

- Construction: Structural and architectural brackets made with materials suited for exterior and interior applications, supporting custom metal fabrication needs.

- Medical Equipment: Specialized brackets designed with strict tolerances and hygiene standards, leveraging our HYCNC custom CNC solutions for precise manufacturing.

Case Study Teaser

Recently, we partnered with a local industrial equipment manufacturer for custom sheet metal bracket fabrication. They needed brackets that could withstand heavy loads without compromising fit or finish. Our team applied advanced sheet metal design for manufacturability principles and CNC precision to deliver parts on time. The result was better performance on the factory floor and lower overall costs due to the exact fit and durable material choices.

If you’re in any of these sectors or have a unique bracket challenge, HYCNC’s local expertise and custom metal fabrication services are ready to support your projects.

Why Choose HYCNC for Custom Sheet Metal Bracket Fabrication

When it comes to custom sheet metal bracket fabrication, HYCNC stands out for several strong reasons. We combine experience, local knowledge, and a customer-first approach to deliver exactly what you need with precision and efficiency.

Expertise in Precision CNC Bracket Fabrication

Our team at HYCNC specializes in precision CNC bracket fabrication and offers comprehensive custom metal fabrication services. Whether you need stainless steel bracket manufacturing or intricate designs requiring advanced CNC laser cutting brackets, we have the skills and the state-of-the-art equipment to handle it. We focus on sheet metal design for manufacturability, ensuring your brackets are not just custom but also practical and reliable.

Local Advantage for Faster Turnaround

Operating locally means faster communication, quicker order fulfillment, and easier site visits if needed. When you search for local sheet metal fabrication near me, HYCNC is your go-to partner because we understand the specific needs of businesses in the United States and tailor our services accordingly. This local presence allows us to deliver your custom components promptly without sacrificing quality.

Customer Centric Service Approach

At HYCNC, customer satisfaction drives everything we do. From the initial design consultation to the final delivery, we work closely with you to ensure the product fits your exact requirements. We provide clear updates, flexible scheduling, and technical support to avoid delays or surprises, making the fabrication process smooth and stress-free.

Certified Quality You Can Trust

We maintain industry certifications that guarantee high standards in every project. Our commitment to quality control means your custom sheet metal brackets meet or exceed industry standards for durability and precision. These certifications back our promise to deliver industrial bracket applications that last and perform perfectly under real-world conditions.

By choosing HYCNC for your custom sheet metal bracket needs, you’re not just getting a product—you’re getting a reliable partnership with a team that understands your business and delivers top-tier custom CNC solutions every time.

How to Get Started with HYCNC for Custom Sheet Metal Bracket Fabrication

Starting your project with HYCNC’s custom sheet metal bracket fabrication services is simple and designed to save you time while ensuring quality. Here’s how you can get going with precision CNC bracket fabrication tailored for your needs:

Step 1 Request a Quote

Reach out to HYCNC with your project details, including dimensions, materials, and any specific design requirements. Our team will quickly review and provide a competitive estimate based on your custom sheet metal components.

Step 2 Share Your Design Files or Ideas

If you have CAD designs or specific drawings, send them over. Need help designing for manufacturability? HYCNC offers expert guidance to optimize your sheet metal design for durability and cost-efficiency. This step ensures your brackets meet your exact specifications.

Step 3 Confirm Material and Process Choices

Choose from a variety of metals such as stainless steel, aluminum, or mild steel, along with fabrication services like CNC laser cutting, metal bending, and surface finishing. We’ll help you pick the right materials and techniques that fit your application and budget.

Step 4 Production and Quality Checks

Once approved, we begin fabrication using our advanced CNC machinery and sheet metal bending techniques. Every custom bracket undergoes strict quality checks to ensure precision and fit, minimizing waste and delays.

Step 5 Fast Delivery and Support

Get your custom sheet metal brackets delivered on time, ready to install in your project. Plus, HYCNC stands by you with local customer support for any follow-up needs or additional runs.

Ready to start your project with a local sheet metal fabrication provider you can trust? Contact HYCNC today to get a free quote and expert advice for your custom sheet metal bracket fabrication needs. Whether you need stainless steel bracket manufacturing, complex CNC router services, or industrial bracket applications, we have you covered.

For more details on optimizing your design, check out our guide on designing sheet metal using SolidWorks.

Choose HYCNC for custom CNC solutions tailored locally with precision, speed, and cost-efficiency. Let’s build your next project bracket with confidence.