What Are Sheet Metal Surface Finishes

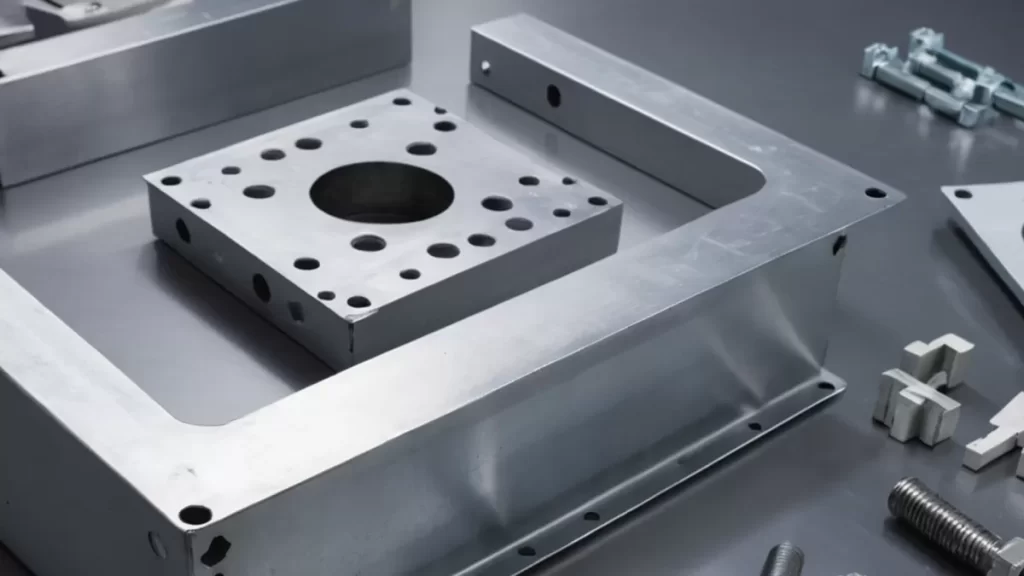

Sheet metal surface finishes refer to the treatments applied to the outer layer of metal sheets to improve their appearance, durability, and performance. These finishes can range from simple polishing and grinding to advanced coatings and chemical treatments. The right surface finish protects the metal from corrosion, enhances its aesthetic appeal, and prepares it for further manufacturing processes like painting or welding.

Finishes are critical because sheet metal often faces harsh environmental conditions, wear, and mechanical stress. Without the proper finish, metals like aluminum, stainless steel, or galvanized steel can rust, degrade, or lose their structural integrity. A quality surface finish also helps in reducing friction, improving cleanliness, and ensuring safety for specific applications.

In short, sheet metal surface finishes serve both protective and functional roles, making them essential in ensuring that your metal parts last longer, perform better, and meet industry standards.

Types of Sheet Metal Surface Finish Options

When it comes to sheet metal surface finish options, there are several common types to consider. Each one changes the look, feel, and function of the metal in different ways.

Mechanical Finishes

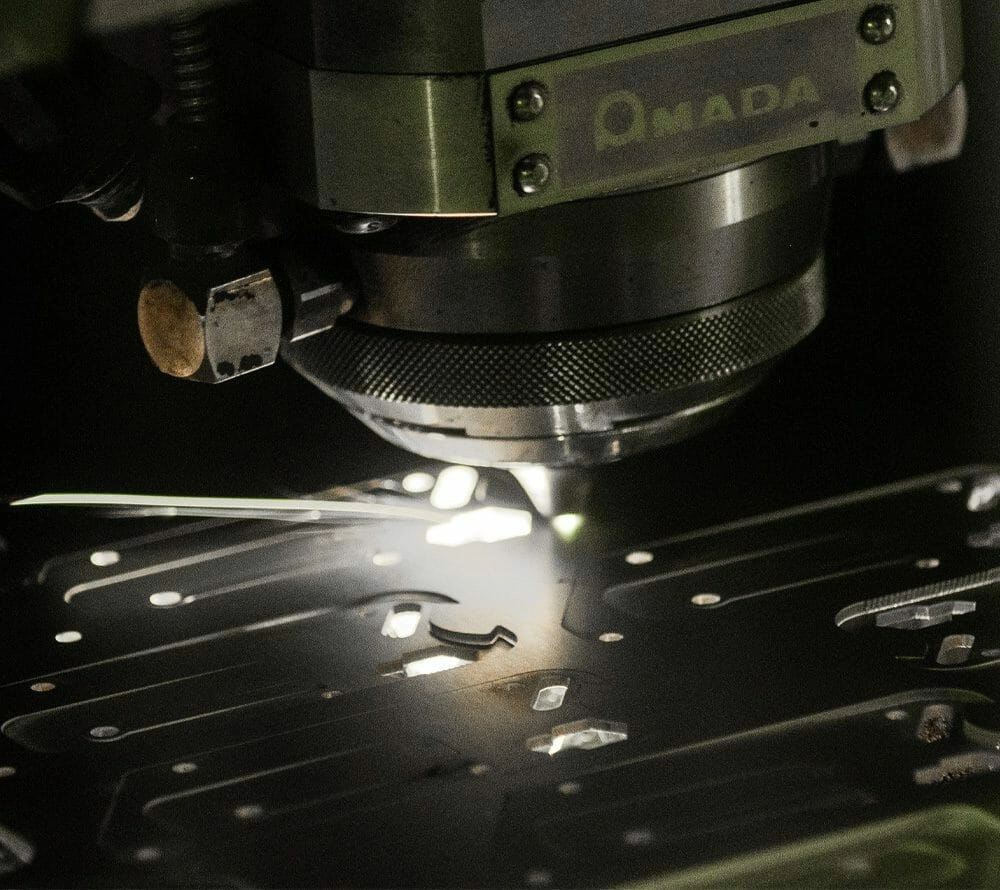

These finishes involve physically altering the surface with tools or abrasives. Some popular mechanical finishes include:

- Grinding and Polishing: Smooths the surface to a shiny or matte appearance.

- Bead Blasting: Uses tiny glass beads to create a uniform, textured finish that reduces glare.

- Brushing: Leaves fine lines on the metal, giving it a satin look often seen on stainless steel.

Chemical and Electrochemical Finishes

These finishes rely on chemical reactions or electric current to treat the metal’s surface. Common types are:

- Anodizing: Especially common for aluminum, this process thickens the oxide layer to improve corrosion resistance and add color options.

- Electroplating: Applies a thin layer of metal (like nickel or chrome) for decoration or protection.

- Chemical Etching: Removes surface layers to create patterns or clean imperfections.

Coating Based Finishes

Coatings add a protective or decorative layer on top of the metal. Key options include:

- Powder Coating: A dry powder is applied electrically and then baked on, offering durable color and corrosion resistance.

- Painting: Traditional paint layers can be used for color and protection but may require regular maintenance.

- Clear Coating: Adds a protective transparent layer to preserve the metal’s natural look and prevent rust.

Specialty Finishes

Some finishes are designed for very specific needs or appearances:

- Passivation: Common with stainless steel, this removes free iron to boost corrosion resistance.

- Electropolishing: Uses electrical current and acid to smooth and brighten stainless steel surfaces, often for medical or food-grade products.

- Textured Finishes: Custom patterns or roughness levels that cater to unique design or grip requirements.

Each type of finish has benefits depending on your project needs, whether it’s for protection, aesthetics, or performance. At HYCNC, we can guide you to the right finish based on your specific sheet metal fabrication work and usage.

Industry Specific Applications of Sheet Metal Finishes

Sheet metal surface finishes play a big role across various industries, each with its own unique needs. Here’s how finishes matter in some key sectors:

Aerospace

In aerospace, finishes need to meet strict standards for durability and corrosion resistance. Lightweight metals like aluminum often undergo anodizing or electroplating to protect parts from harsh environments while keeping weight down. Smooth finishes also help reduce drag and improve fuel efficiency.

Automotive

The automotive world relies heavily on sheet metal finishes for aesthetics and protection. Powder coating for sheet metal is common for exterior parts, while stainless steel surface finishes inside engines and exhaust systems boost corrosion resistance. Polished or brushed finishes provide a sleek look for trim and interior panels.

Medical

Medical devices demand flawless, easy-to-clean sheet metal surfaces. Finishes like metal polishing methods and precision CNC metal surface finishing ensure there are no rough spots to harbor bacteria. Corrosion-resistant finishes are critical for surgical instruments and implants.

Architectural

Architectural projects often highlight metal finishes for both style and weather resistance. Bead blasting sheet metal, anodizing, and powder coating offer options that stand up to outdoor conditions while providing clean, modern aesthetics.

Consumer Goods

For everyday products like appliances and electronics, finishes improve durability and look. Common choices include brushed stainless steel, powder coatings, and polished surfaces that resist fingerprints and scratches. Custom sheet metal fabrication often includes specialized finishes to meet brand standards and product function.

Each industry uses specific sheet metal finishing techniques to match performance demands, appearance, and longevity—helping products perform better and last longer in their environments.

How to Choose the Right Surface Finish for Your Project

Picking the right sheet metal surface finish can make a big difference in both how your part performs and how it looks. Here are some key things to think about:

- Material type: Different metals react differently to finishes. For example, anodizing works great on aluminum, while stainless steel often benefits from bead blasting or polishing.

- Function: Will the part face harsh conditions, like corrosion or wear? If yes, look for corrosion-resistant metal finishes like electroplating or powder coating.

- Appearance: Are you after a shiny, matte, or textured look? Mechanical finishes like polishing and brushing offer distinct visual effects.

- Budget and timeline: Some finishes take longer or cost more. Powder coating and electroplating add extra steps and price, so plan accordingly.

- Industry requirements: Certain sectors, like aerospace and medical, have strict surface finish rules for safety and performance.

At HYCNC, we understand these details and help you choose the right CNC metal surface finishing technique tailored to your project’s needs. Whether you need expert advice on custom sheet metal fabrication or want to optimize your finish for durability and style, our team guides you every step of the way.

For more about our finishing services and how they integrate with your overall project, visit our surface finishing services page. If you’re combining finishing with fabrication, check out our sheet metal fabrication options to get a complete package.

Choosing the right finish isn’t just about looks—it’s about making your part perform better and last longer. We make sure you get it right.

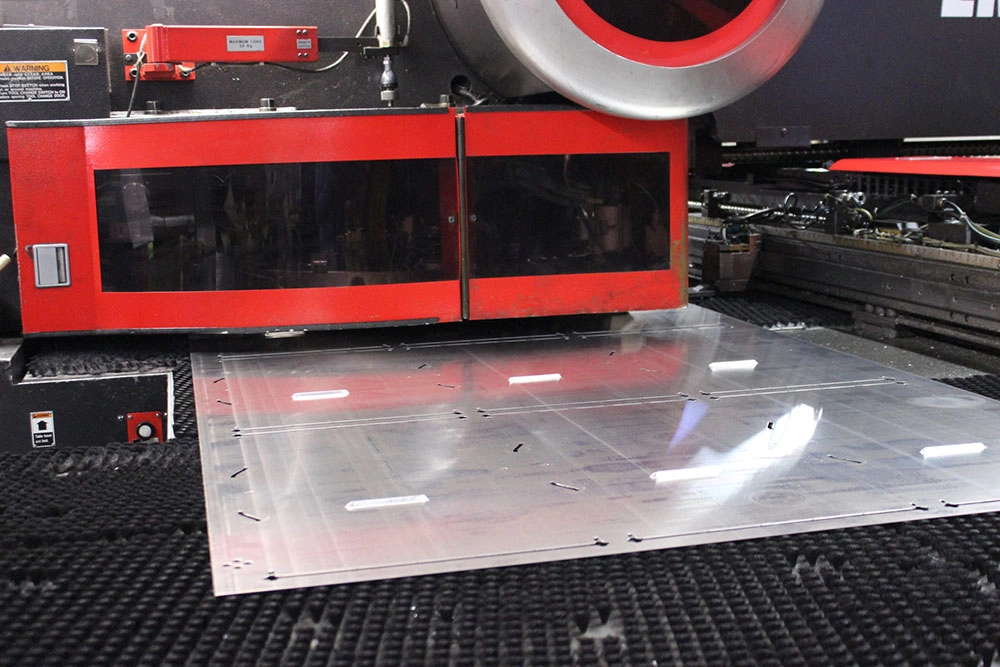

HYCNC’s Sheet Metal Finishing Capabilities

At HYCNC, we bring advanced CNC finishing services to the table, ensuring your sheet metal parts get the perfect surface finish every time. Our precision CNC metal surface finishing techniques allow us to achieve smooth, consistent results tailored to your project’s exact needs.

Customization and Precision

No two projects are the same, which is why we offer fully customizable finishing options. Whether you need bead blasting sheet metal for a matte texture, anodizing aluminum parts for added corrosion resistance, or electroplating metal parts to enhance durability and appearance, we’ve got you covered. Our team works closely with you to select the right finish based on your application, material, and budget.

Fast Turnaround and Quality Assurance

We know timing is key in manufacturing. That’s why HYCNC prioritizes fast turnaround times without sacrificing quality. Every sheet metal finish undergoes strict quality checks to meet industry standards and your specific requirements. Combining state-of-the-art CNC service with expert craftsmanship, we deliver reliable, repeatable results that keep your production on schedule.

For more on how we handle sheet metal projects from start to finish, check out our sheet metal fabrication process.

Common Challenges and Solutions in Sheet Metal Finishing

When working with sheet metal surface finish options, a few challenges often pop up. Here’s how we tackle them:

Surface Imperfections

- Scratches, dents, or rough patches can happen during cutting, bending, or handling.

- We use precise CNC metal surface finishing techniques like bead blasting or polishing to smooth out imperfections.

- Regular inspections during production help catch issues early, minimizing rework.

Cost Management

- Finishing processes can add up, especially with specialty coatings like powder coating for sheet metal or anodizing aluminum parts.

- We suggest balances between performance and budget, recommending finishes that protect and perform without overdoing it.

- Custom sheet metal fabrication from HYCNC includes options that fit your price range without sacrificing quality.

Consistency

- Achieving uniform finishes across batches is critical, especially in industries like aerospace or medical where quality standards are strict.

- Our advanced CNC finishing services use automated processes and skilled operators to maintain consistent results every time.

- We keep tight quality controls and detailed records to ensure repeatable finishes across all your projects.

At HYCNC, we understand these challenges and work closely with you to find the best, cost-effective solutions for your sheet metal finishing needs.

FAQs

What are common sheet metal surface finish options?

The main options include mechanical finishes like polishing and bead blasting, chemical finishes such as anodizing, electrochemical like electroplating, and coating finishes including powder coating. Specialty finishes are available for unique project needs.

Why is surface finish important for sheet metal?

Surface finishes protect the metal from corrosion, improve appearance, enhance durability, and sometimes provide specific functional properties like better conductivity or resistance to wear.

Can all metals be powder coated?

Most metals can be powder coated, but surface prep varies depending on the metal type. For example, aluminum parts often require anodizing or cleaning before powder coating for best results.

What is the difference between anodizing and electroplating?

Anodizing is an electrochemical process that thickens the natural oxide layer on aluminum, enhancing corrosion resistance and appearance. Electroplating deposits a thin metal layer on the surface, such as chrome or nickel, for protection and aesthetics.

How do I know which sheet metal finishing technique is best for my project?

Consider factors like the metal type, the environment the part will be used in, desired look and feel, budget, and timeline. Consulting with experts helps tailor the finish to your specific needs.

Does HYCNC offer custom sheet metal finishing services?

Yes, HYCNC provides advanced CNC metal surface finishing with customization and precision. They offer quick turnaround and quality assurance for a range of industries.

Where can I learn more about sheet metal fabrication and finishing?

Check out our blog on sheet metal fabrication process materials applications and our detailed surface finishing services to explore options and expert insights.

If you have more questions or a project in mind, feel free to get in touch for tailored advice.