Understanding Sheet Metal Assembly

What is Sheet Metal Assembly

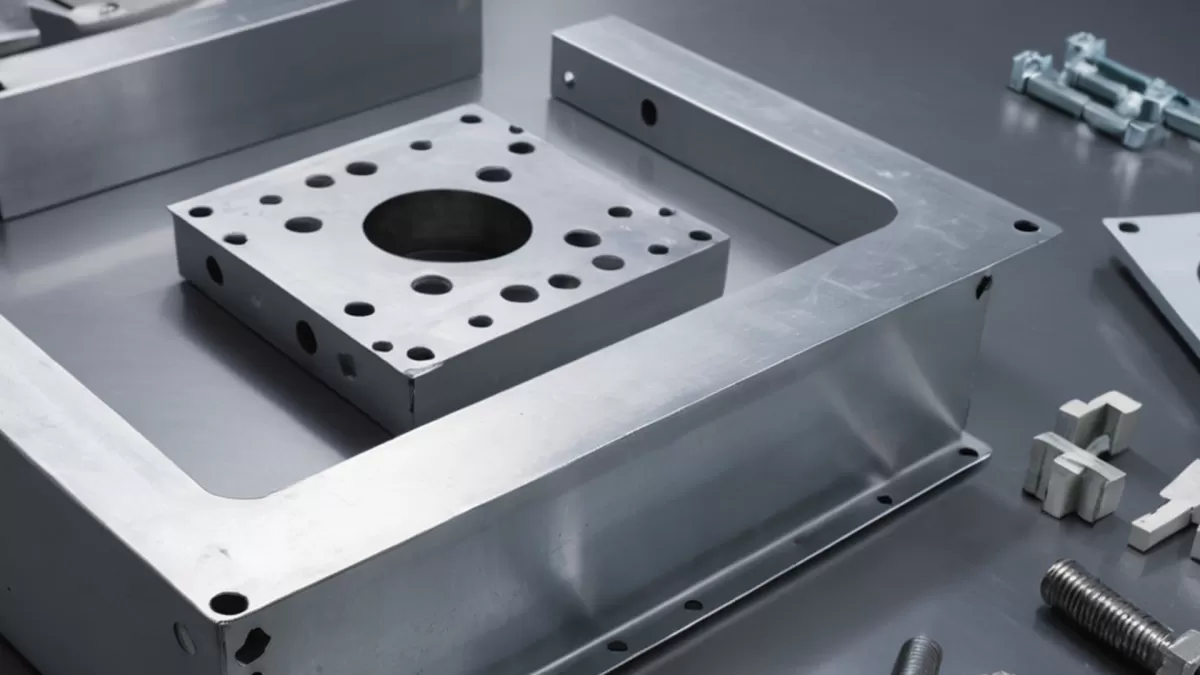

Sheet metal assembly involves joining and fitting individual metal parts to create a complete product or component. This process is essential in industries such as automotive, aerospace, electronics, and construction where precision and durability are critical. The goal is to combine sheet metal pieces through various techniques like welding, riveting, or mechanical fastening to achieve a functional, strong, and properly aligned final product.

Key Elements of Assembly Support Positioning and Clamping

Successful sheet metal assembly depends heavily on support, positioning, and clamping. These elements ensure parts stay fixed and aligned during assembly, preventing movement that can cause misalignment or damage.

- Support: Stable fixtures and work surfaces help maintain part integrity.

- Positioning: Accurate alignment methods such as jigs or templates guide parts into place.

- Clamping: Secure clamps hold parts firmly to avoid shifting during joining processes like welding or riveting.

Proper control of these factors reduces errors, maintains tight tolerances, and improves the overall quality of sheet metal fabrication. Mastering this foundation sets the stage for efficient and reliable assembly outcomes. For more detailed insights into sheet metal fabrication and related processes, check out our guide on sheet metal fabrication process materials applications.

Best Practices for Assembling Sheet Metal Parts

When assembling sheet metal parts, following best practices ensures a smooth build and high-quality results. Here’s what you need to focus on:

Design for Manufacturing and Assembly DfMA

Start with the design. Keep it simple and efficient to reduce manufacturing time and cost. Designing with DfMA principles means thinking ahead about how parts fit together and how easy they are to assemble. This approach avoids complex shapes and tight clearances that cause headaches during assembly.

Choosing the Right Assembly Techniques

Picking the right assembly methods makes a big difference. Options include:

- Sheet metal bending to shape parts correctly before assembly

- Welding sheet metal when permanent bonds are needed

- Riveting metal parts for strong, removable joints

- Mechanical fasteners for flexibility

Match your technique to the material, part function, and expected durability.

Avoiding Common Mistakes

Watch out for these pitfalls:

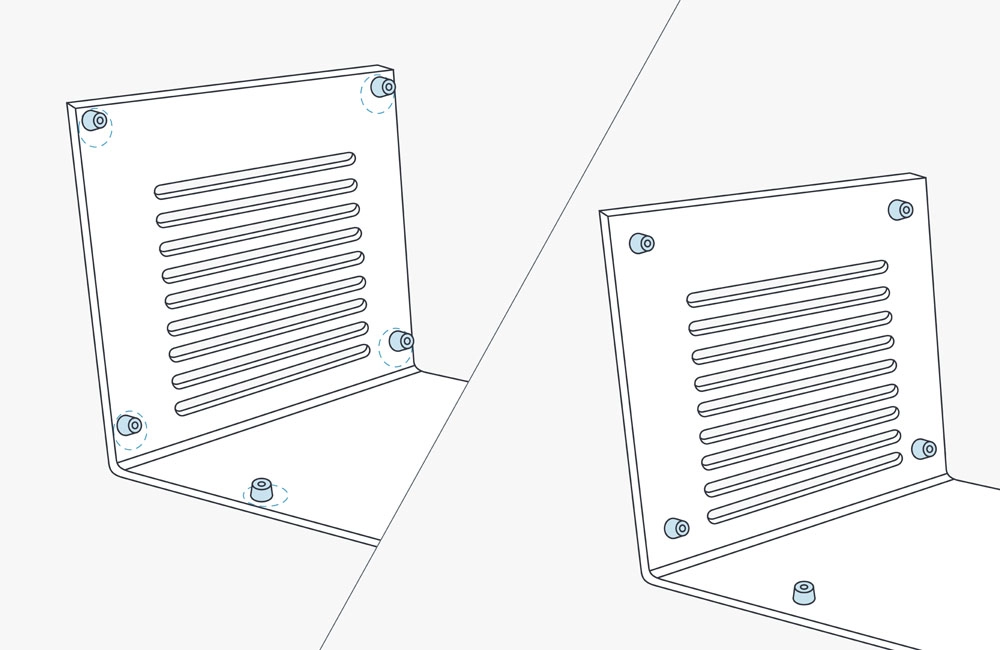

- Skipping proper positioning and clamping, which leads to misalignment

- Using incorrect fasteners that don’t match material thickness or type

- Ignoring the effects of heat during welding, which can warp or weaken metal

Good preparation reduces these risks.

Optimizing Tolerances and Precision

Precision matters. Setting realistic tolerances in sheet metal helps parts fit well without extra force or gaps. Overly tight tolerances might increase costs or cause fit issues, while too loose can reduce product quality. Coordinate with your CNC machining service provider to balance precision with practicality.

By applying these best practices, you’ll improve build quality, save time, and avoid costly fixes down the road.

Tools and Equipment for Effective Assembly

Essential Tools for Sheet Metal Assembly

When it comes to assembling sheet metal parts, having the right tools makes all the difference. Some must-haves include:

- Clamps and Fixtures to hold parts in place securely during welding or riveting

- Sheet Metal Benders and Brakes for accurate shaping and fitting

- Riveting Tools and Welding Machines for strong, lasting joints

- Measuring Instruments like calipers and micrometers to check tolerances and alignment

- Hand Tools such as screwdrivers, pliers, and hammers for fit adjustments

Using these tools properly helps ensure precision assembly and keeps metal parts aligned, minimizing errors and rework.

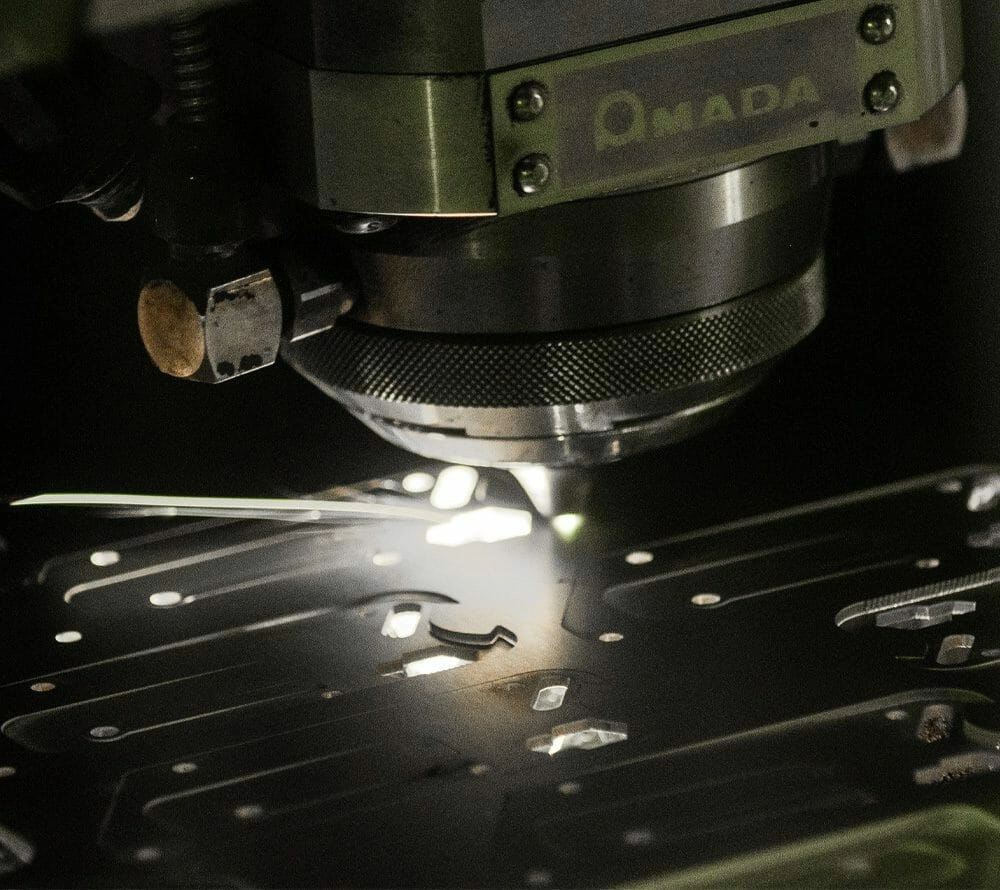

Role of Automation in Assembly

Automation is becoming a game-changer in sheet metal fabrication. CNC machining services and robotic welding systems speed up production and improve consistency. Here’s how automation helps:

- Improves precision by following exact programming

- Reduces manual labor for repetitive tasks like bending or drilling

- Enhances speed while keeping quality high

- Ensures consistent tolerances across batches

For manufacturers in the U.S. looking to boost efficiency, integrating CNC processing solutions with manual assembly techniques offers the best of both worlds—precision and flexibility.

Material Selection for Sheet Metal Assembly

Choosing the right material is a critical step when assembling sheet metal parts. The material you pick affects not only the ease of fabrication but also the durability and performance of the final product. Common materials include stainless steel, aluminum, and carbon steel, each offering different strengths, corrosion resistance, and weight.

Choosing the Right Material

- Stainless Steel: Great for corrosion resistance and strength, often used in outdoor or harsh environments.

- Aluminum: Lightweight and easy to work with, making it ideal for applications where reducing weight is important.

- Carbon Steel: Affordable and strong, but may require coatings or treatments to prevent rust.

Impact of Material on Assembly

Material affects how parts bend, fasten, and hold up under stress. For example:

- Bending and Forming: Softer metals like aluminum bend easier, while harder metals need more precise CNC machining or stamping.

- Joining Techniques: Welding sheet metal behaves differently depending on the material; aluminum requires different processes compared to steel.

- Tolerance Management: Different materials expand or contract under heat, so understanding this helps maintain precision assembly.

Knowing how your material choice influences the assembly process can save time and cost. For more detailed info on materials and sheet metal fabrication, check out HYCNC’s sheet metal fabrication services.

How HYCNC Simplifies Sheet Metal Assembly

When it comes to assembling sheet metal parts, HYCNC stands out by offering precise CNC processing solutions that streamline the entire process. Their advanced CNC machining services ensure every metal part is cut, bent, and shaped with tight tolerances, making assembly faster and more accurate. This precision reduces errors like misalignment and deformation, which are common challenges in sheet metal fabrication.

HYCNC’s CNC Processing Capabilities

- High-precision cutting and bending for consistent part quality

- Support for complex designs thanks to flexible CNC programming

- Quick turnaround times to keep your projects on schedule

- Integration of drilling, welding, and riveting to prepare parts for assembly

- Reliable metal part alignment due to tight tolerance control

Why Choose HYCNC for Your Assembly Needs

- Experience with a wide range of sheet metal materials to match your application

- Expertise in Design for Manufacturing and Assembly (DfMA) to optimize your parts for easy assembly

- Use of automation to speed up production without sacrificing quality

- Responsive customer service tuned to U.S. industry standards and deadlines

Choosing HYCNC means you get a partner that understands the ins and outs of sheet metal assembly. Their CNC processing expertise not only improves the fit and finish of your parts but also cuts down on costly rework and delays — a big win for any manufacturing operation in the U.S.

Troubleshooting Common Assembly Challenges

Dealing with Deformation and Misalignment

When assembling sheet metal parts, deformation and misalignment are common issues that can throw off your entire project. Metal can bend or warp during processes like bending, welding, or even handling. To tackle this:

- Use proper clamping and fixturing to hold parts securely in place.

- Check alignment frequently during assembly to catch misfits early.

- Control heat input during welding or joining to reduce warping.

- Work with precise CNC machining services for consistent part accuracy that minimizes alignment problems.

- Apply corrective bending or reshaping when minor deformations occur.

Keeping tolerances tight and working with experienced fabricators can significantly reduce these headaches.

Addressing Surface Quality Issues

Surface finish plays a big role in both the appearance and functionality of sheet metal assemblies. Scratches, burrs, or surface irregularities can affect how parts fit together or how they perform.

To maintain quality surfaces:

- Inspect and deburr all edges after cutting or stamping.

- Use appropriate finishing techniques such as grinding, polishing, or sanding.

- Control sheet metal bending and forming parameters to avoid cracks or surface damage.

- Choose materials with good surface properties suitable for your assembly.

- Implement quality checks at every stage of the assembly process to catch defects early.

Proper handling and finishing ensure your assembled parts look professional and function as intended without surface flaws.

For more on preventing deformation and managing surface finishes, check out our detailed guide on sheet metal fabrication processes. Also, learn how design for manufacturing and assembly strategies can help reduce common assembly challenges.