Understanding Laser Cutting Design Software

What is Laser Cutting Design Software

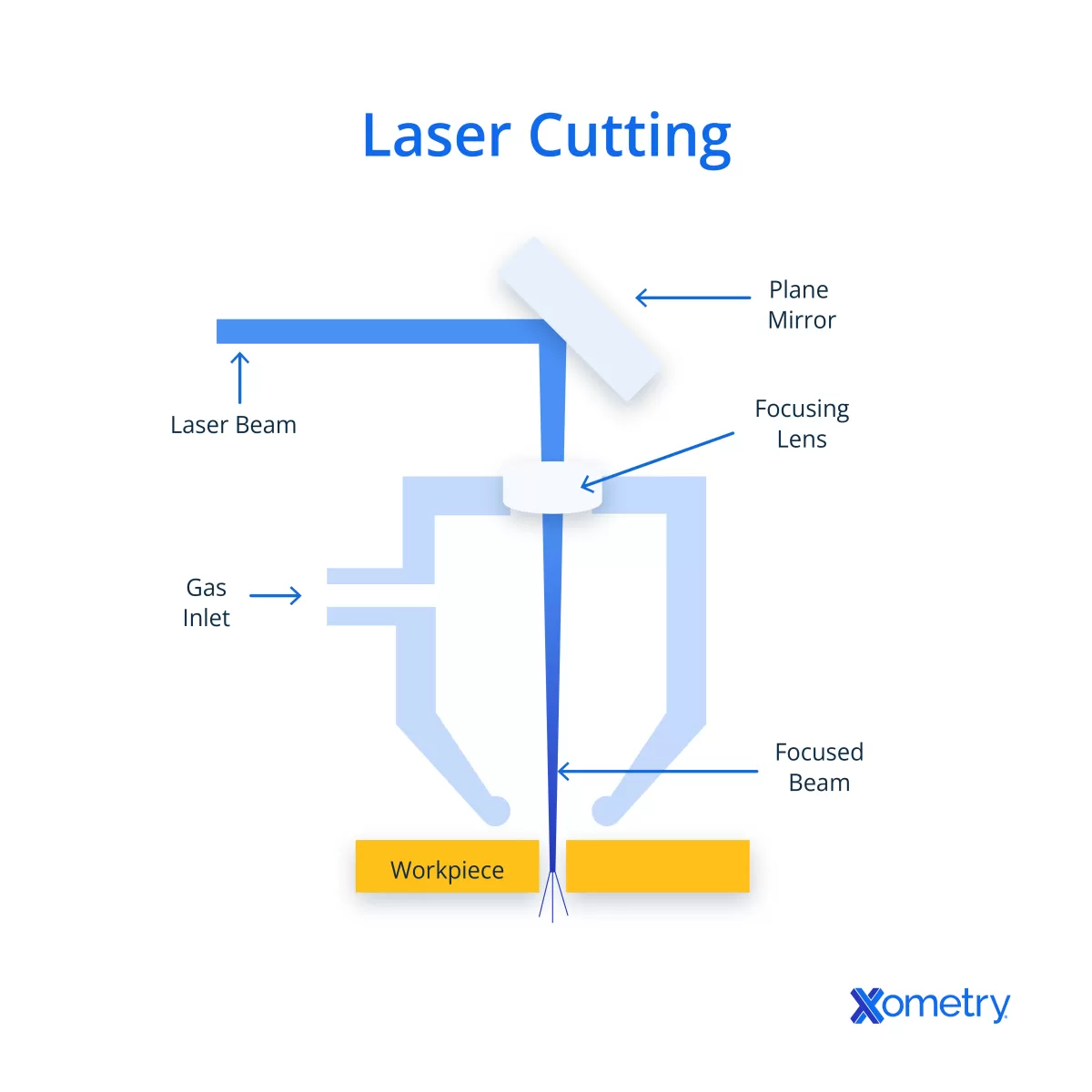

If you’re new to laser cutting, one of the first questions might be: what exactly is laser cutting design software? Simply put, it’s the computer program you use to create and prepare artwork or patterns that a laser cutter will follow to cut or engrave materials. These programs help transform your creative ideas into precise digital files that the CNC laser cutting tools can read.

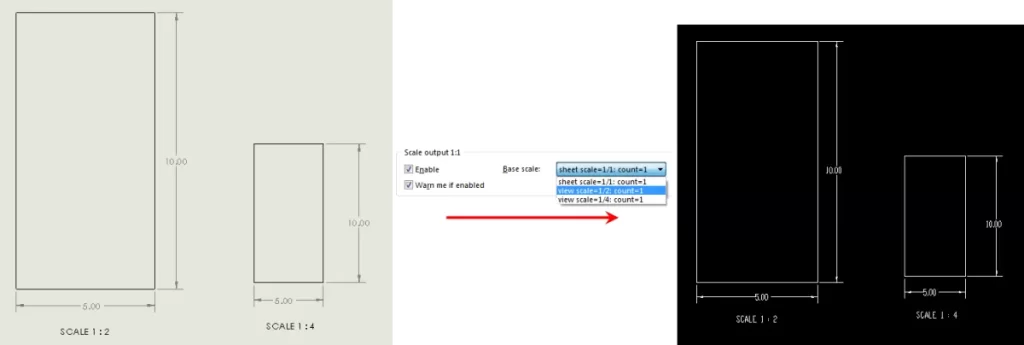

Laser cutting design software typically works with vector graphics. Vector designs use paths and points instead of pixels, which means they can be scaled without losing quality—perfect for the sharp, clean lines required in laser cutting. This software also helps you manage details like cut lines, engraving areas, and even the order of operations.

In short, laser cutting design software is your bridge between creativity and the physical output—a crucial tool if you want consistent, professional results from your laser cutter. Whether you’re working on small DIY projects or large-scale production, choosing the right software can make a big difference in ease and efficiency.

Key Features to Look For in Laser Cutting Design Software

When choosing the best laser cutting design software, there are a few must-have features to keep an eye on. These features help ensure your designs come out clean and your CNC laser cutting tools work smoothly.

Vector Design Support

Laser cutting relies on precise vector paths, so your software needs strong vector design capabilities. Look for tools that let you create and edit lines, curves, and shapes easily.

File Compatibility

Make sure the software supports common laser cutting file formats like DXF, SVG, AI, or PDF. This ensures your design files work seamlessly with different CNC machines and laser cutters.

G-Code Generation

If you want to run CNC laser cutting directly, the software should create or export G-code – the instructions your laser cutter reads to cut accurately.

User-Friendly Interface

Whether you’re a beginner or pro, the design software should be intuitive and straightforward. Smooth navigation speeds up your workflow and reduces mistakes.

Editing Tools

Look for clean editing features like scaling, rotating, node editing, and path merging. These help you refine your designs without fuss.

Layer Management

Good software allows you to work with layers to separate different cutting, engraving, or marking tasks in one file. This feature helps with complex projects and saves time.

Cost and Licensing

Some laser cutting software is free or open source, while others require licenses or subscriptions. Consider your budget and how regularly you’ll use the software.

Keeping these key features in mind will help you pick the right software to match your CNC laser cutting tools and project goals.

Why Laser Cutting Design Software Matters

Laser cutting design software is more than just a tool—it’s the foundation for creating precise, high-quality cuts that bring your ideas to life. Whether you’re working on a small DIY project or managing large-scale production, the right software ensures your designs translate accurately to the laser cutter. This matters because:

- Accuracy and Precision: Good software helps you create detailed vector paths and shapes that the laser cutter follows exactly, reducing errors and material waste.

- Efficiency: Efficient design tools speed up your workflow, letting you move quickly from concept to finished piece.

- File Compatibility: Compatible software supports common laser cutting file formats like DXF, SVG, and AI, ensuring smooth communication with different CNC laser cutting tools.

- Customization: Powerful design software makes it easy to tweak and customize your designs for specific materials or thicknesses, which means better results every time.

- Cost Savings: Minimizing mistakes and material waste directly lowers your project costs, making your laser cutting ventures more profitable.

Using the best laser cutting software is essential to keep your projects on track and deliver results that meet your expectations. It’s about getting the most out of your CNC laser cutting setup and maximizing your creative potential.

If you want to explore more about design optimization in CAD, check out our guide on design optimization in CAD.

Top 6 Laser Cutting Design Software Options for 2025

Adobe Illustrator

Adobe Illustrator stands out as one of the best laser cutting design software options for 2025. It’s a powerful vector design software widely used by professionals for creating precise, clean designs that laser cutters require. Illustrator lets you create detailed shapes and paths which easily translate into laser cutting file formats like SVG, DXF, and AI.

What makes Illustrator a top choice?

- Precision tools for detailed design work

- Wide compatibility with most CNC laser cutting tools

- Customizable artboards to fit various material sizes

- Integration with other Adobe apps for a smooth design workflow

- Strong text and shape manipulation features

While it comes with a subscription fee, the investment pays off if you need professional-grade CAD software for laser cutting. Illustrator also supports advanced layering and color management, which are great for prepping designs for multi-pass cuts or engraving.

For laser cutting beginners in the US looking to step up their design game, Adobe Illustrator offers reliable, industry-standard tools to make your projects look sharp and precise.

Inkscape

Inkscape is a popular free vector design software that’s great for laser cutting beginners and pros alike. It’s open-source, meaning you don’t have to pay to use it, and it supports common laser cutting file formats like SVG and DXF. You can create detailed designs, convert them into paths, and prepare files compatible with many CNC laser cutting tools.

What makes Inkscape stand out is its user-friendly interface paired with powerful features like node editing, layer management, and trace bitmap for converting images into cuttable vectors. It also works well for G-code generation when combined with plugins or additional tools, making it versatile for different laser cutters.

If you’re focused on finding free laser engraving software or design software for laser cutters that won’t break the bank but still gets the job done smoothly, Inkscape should be on your list. It’s especially useful if you’re looking to experiment with laser cutting designs without upfront costs.

LightBurn

LightBurn is a favorite among many hobbyists and professionals for its straightforward approach to laser cutting design. It’s a full-featured laser cutting software that handles everything from creating designs to generating the G-code your machine needs to cut or engrave. Unlike some vector design software that requires separate post-processing, LightBurn combines both design and control in one place.

What makes LightBurn stand out for 2025 is its compatibility with numerous CNC laser cutters and its user-friendly interface, which doesn’t overwhelm beginners but still offers advanced tools for experienced users. It supports multiple file formats, including SVG and DXF, making it flexible for importing your designs from other platforms.

Key highlights of LightBurn:

- Integrated design and laser control software

- Supports various laser cutters and file formats

- Easy G-code generation with customizable cutting parameters

- Layer-based workflow for organizing complex jobs

- Active community and ongoing updates

If you’re looking for software that simplifies the process from design to laser cutting without juggling multiple programs, LightBurn should be on your radar. Plus, its range of features supports both beginners and pros, making it an excellent option for different project levels.

For more insight on design file preparation, check out our guide on preparing text for laser cutting in Inkscape, which can complement your work with LightBurn.

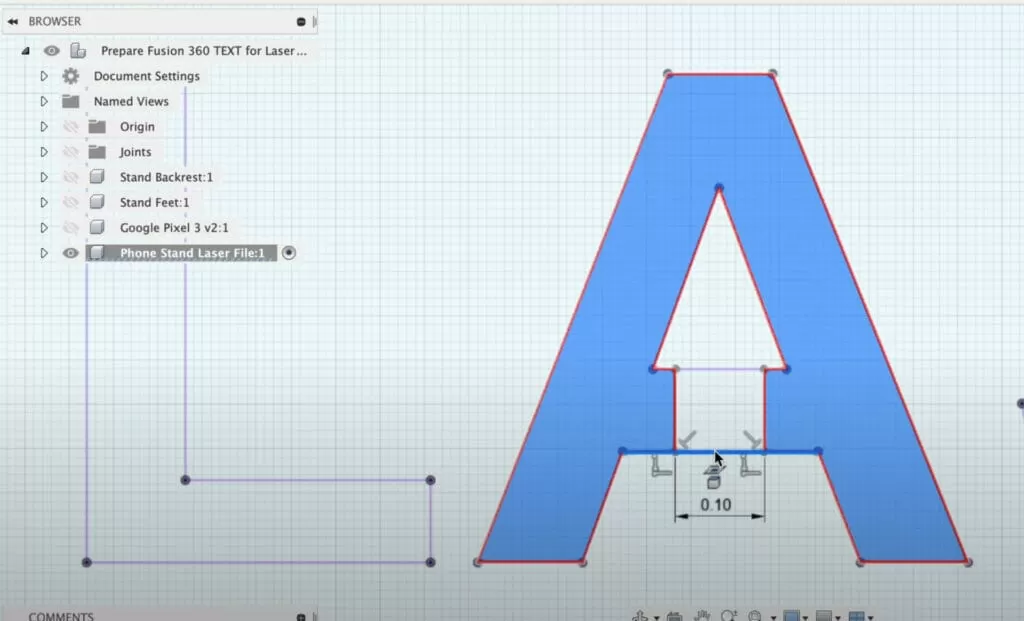

Fusion 360

Fusion 360 is a powerful all-in-one CAD software favored by many for laser cutting and CNC projects. It combines 3D modeling, design, and manufacturing tools, making it ideal for users who want to go beyond simple 2D designs. If you need precise control over complex parts or want to create prototypes and finished products, Fusion 360 has you covered.

Why Fusion 360 stands out:

- Advanced design features: Create detailed 3D models or 2D sketches suited for laser cutting.

- Integrated CAM tools: Generate G-code directly for CNC laser cutters.

- Cloud-based collaboration: Work on projects across multiple devices and teams without hassle.

- Strong community and support: Plenty of tutorials, forums, and resources for beginners and pros alike.

For U.S.-based makers and small businesses looking for best CAD software for laser cutting with a blend of design versatility and CNC integration, Fusion 360 remains a top choice. It’s great if you want to scale your projects and need software that grows with your skills.

CorelDRAW

CorelDRAW is a solid choice when it comes to the best laser cutting design software in 2025. It’s popular for its powerful vector design tools that make creating precise and detailed laser cutting files easy. Whether you’re designing signs, decals, or intricate art pieces, CorelDRAW handles complex shapes and layers well.

Key reasons to consider CorelDRAW include:

- User-Friendly Interface: Easy to pick up, especially if you’re used to Adobe products but want a simpler alternative.

- Strong File Compatibility: Supports common laser cutting file formats like DXF and SVG, so your designs work smoothly with most CNC laser cutting tools.

- Advanced Vector Editing: Offers many tools for shaping, trimming, and aligning paths, which is crucial for accurate laser engraving and cutting.

- Customizable Workspaces: You can set up your screen and tools exactly how you prefer, speeding up the designing process.

- Good for Beginners and Pros: From simple projects to complex 3D effects, it scales with your skill level.

CorelDRAW also integrates well with HYCNC laser cutting services, making it easier to export files that align perfectly with their CNC machining standards. If you want reliable design software that fits a range of laser cutting needs, CorelDRAW is definitely worth a look.

LaserGRBL

LaserGRBL is a popular choice if you’re looking for free laser cutting software that’s easy to use, especially for beginners. It’s designed to work well with low-power laser engravers and CNC laser cutting tools, making it perfect for hobbyists and small projects.

Key points about LaserGRBL:

- Free and open-source software, so no upfront cost.

- Supports common laser cutting file formats like G-code and BMP, which helps in smooth job setup.

- Simple interface that’s great if you’re just starting with laser cutting.

- Handles G-code generation, so you can go straight from design to cutting without extra conversion steps.

- Best for Windows users — it doesn’t have Mac or Linux versions yet.

LaserGRBL is not as advanced as some paid design software but shines when it comes to straightforward engraving and cutting tasks. If you’re new to laser cutting or just need reliable free software for your HYCNC projects, this is a solid option to try.

How to Choose the Right Software for Your CNC Projects

Factors to Consider

Picking the right laser cutting design software for your HYCNC projects means balancing your needs with what the software offers. Here are some key factors to keep in mind:

- Compatibility: Make sure the software works well with HYCNC’s CNC laser cutting tools and supports the file formats they accept, like DXF, SVG, or AI.

- Ease of Use: Especially if you’re new to laser cutting, choose software with a friendly interface and helpful tutorials. It should simplify your workflow, not complicate it.

- Design Features: Look for vector design software that offers layers, editing tools, and precise control to create clean lines for laser cutting.

- G-code Generation: The software should efficiently convert your designs into G-code so HYCNC’s machines can accurately produce your parts.

- Cost: Consider your budget—whether you want free laser engraving software like Inkscape or more robust paid options like Fusion 360 or CorelDRAW.

- Support and Updates: Reliable customer support and regular software updates help keep your designs compatible with the latest CNC machining tech.

By considering these factors, you’ll choose the best CAD software for laser cutting that fits your HYCNC project needs and helps you get the most out of your designs.

HYCNC Workflow Integration

Choosing the right laser cutting design software means making sure it fits smoothly into HYCNC’s workflow. It’s not just about picking the best software out there but selecting one that works well with the files and formats HYCNC uses. Here’s what to keep in mind:

- File Compatibility: Make sure the software supports common laser cutting file formats like DXF, SVG, or AI. HYCNC’s machines read these easily, which means fewer headaches during file transfers.

- G-Code Export: If you want more control, check if the software can generate G-code or easily export to formats that HYCNC’s CNC laser cutters can handle. This helps streamline the production process.

- Design to Production Flow: Look for design software that lets you finalize your vector designs with precision. Clean, error-free files will reduce delays and revisions with HYCNC.

- Software Updates and Support: HYCNC relies on modern tools that keep improving. Using design software with regular updates ensures your files stay compatible and can take advantage of new cutting features.

Working with software that slots right into HYCNC’s system means your projects get done faster and with higher quality. This smooth workflow integration can save you time and money, especially on complex or high-volume jobs.

For more insight on optimizing your designs with CNC processes, check out our guide on CNC milling part design.

Tips for Beginners Choosing the Right Software for Your CNC Projects

Starting with laser cutting can feel overwhelming, but picking the right software doesn’t have to be. Here are some simple tips if you’re new to HYCNC’s laser cutting services and want the best experience:

- Start with user-friendly software: Look for tools with a clean interface and plenty of tutorials. Programs like Inkscape or LaserGRBL are great for beginners because they’re free and easy to learn.

- Check compatibility with HYCNC systems: Make sure your design software exports common laser cutting file formats like SVG, DXF, or AI. This ensures your files will work smoothly with HYCNC’s CNC laser cutting tools.

- Focus on essential features: Beginners don’t need all the bells and whistles. Prioritize software that supports vector design, basic editing, and G-code generation, which controls laser cutters.

- Use online resources: HYCNC’s website and community forums often have guides and tips for beginners using their laser cutting services. Tap into these for project-specific advice.

- Practice with simple projects: Start small to get comfortable with the workflow from design to finished cut. This builds confidence before moving to complex designs.

- Ask for help if stuck: HYCNC offers support to guide you through software setup or file preparation. Don’t hesitate to reach out—help speeds up your learning curve.

By following these tips, you’ll be on solid ground to create great designs and get the best results from HYCNC’s laser cutting services.

Maximizing Your Designs with HYCNC’s Laser Cutting Services

Why Use HYCNC

When it comes to laser cutting, HYCNC offers more than just basic service – they bring precision and reliability that make your designs stand out. Here’s why choosing HYCNC’s laser cutting services makes sense:

- High Accuracy: HYCNC uses advanced CNC laser cutting tools that deliver precise cuts every time, which means your design details won’t get lost during production.

- Wide Material Range: Whether you’re working with wood, acrylic, metal, or other materials, HYCNC handles it all. This flexibility lets you experiment without worrying about limitations.

- Fast Turnaround: Need your project done on time? HYCNC is known for quick processing, helping businesses and hobbyists meet tight deadlines.

- Expert Support: Got questions about file formats or design tweaks? Their team knows the ins and outs of laser cutting software and can help optimize your files for the best results.

- Custom Solutions: If your project has unique needs, HYCNC offers tailored services that fit your specific CNC or laser cutting workflow.

By working with HYCNC, you’re tapping into a service that understands the American market’s demand for quality, speed, and versatility. Using HYCNC means your laser cutting projects from vector design software to G-code generation run smoothly from concept to finished piece.

Design Tips for CNC

To get the most out of HYCNC’s laser cutting services, here are some smart design tips to keep in mind:

- Use vector formats like AI, SVG, or DXF. These work best with CNC laser cutting tools and help maintain clean, precise lines.

- Keep your lines simple and clear. Avoid overlapping paths or unnecessary details that could confuse the laser cutter.

- Check your line thickness. For cutting, use hairline (usually 0.001 inch or 0.025 mm) lines; for engraving, thicker lines work better.

- Separate cutting and engraving layers in your design file. This helps HYCNC program the job efficiently without errors.

- Design with material in mind. Different materials cut differently—thicker materials need simpler paths and fewer inner cuts.

- Include tabs or bridges in your design if you want parts to stay attached after cutting.

- Avoid very small or intricate details that may not cut well or can burn easily.

- Preview your design in the software before sending it to HYCNC. This can catch issues that save time and money.

- Communicate your project needs clearly with HYCNC, including material type, thickness, and finish preferences.

Following these tips will make your HYCNC

Maximizing Your Designs with HYCNC’s Laser Cutting Services Call to Action

Ready to bring your laser cutting projects to life? HYCNC offers professional CNC laser cutting services that deliver high precision and quality every time. Whether you’re a hobbyist or a business, their expert team and advanced machines handle a wide range of materials with ease.

Don’t settle for less when it comes to your designs. Partner with HYCNC to get accurate cuts, fast turnaround, and support tailored to your needs. If you’re looking for reliable laser cutting services in the U.S., HYCNC is your go-to choice.

Get started today—upload your design, choose your material, and let HYCNC do the rest. Experience the difference that top-notch laser cutting software combined with expert service can make. Contact HYCNC now to elevate your projects!