Why Metal Selection Matters in Custom Fabrication

Choosing the right metal is one of the most important decisions in any custom fabrication project. The type of metal you select directly affects the durability, cost, and overall performance of your finished product. For example, a metal that’s too weak might fail under stress, while one that’s overly expensive could bust your budget without adding real value.

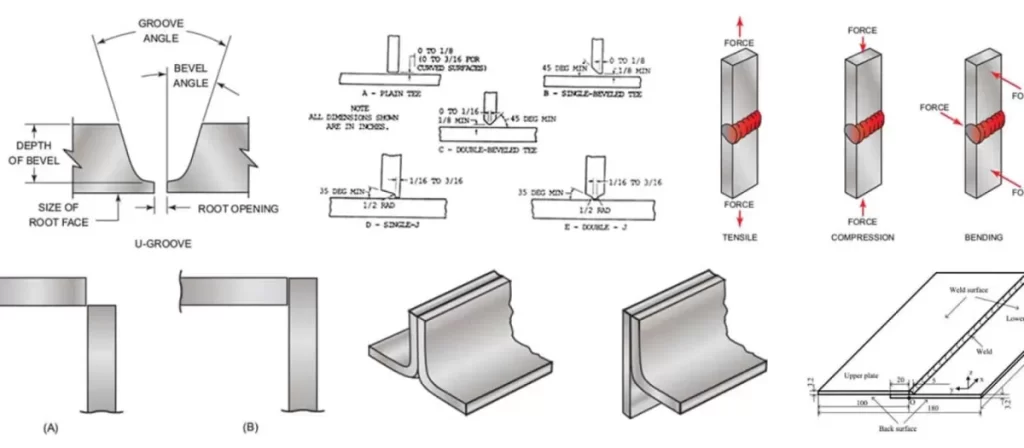

Different metals also respond uniquely to common fabrication processes like CNC machining, laser cutting, and welding. Some metals, like aluminum, are easier to machine and cut precisely, making them ideal for detailed parts. Others, such as stainless steel, offer superior corrosion resistance but need special handling during welding to maintain their strength and appearance.

At HYCNC, we specialize in understanding the strengths and limitations of various metals and matching them perfectly to your project’s specific needs. Our experienced team leverages advanced CNC machining services and laser cutting technology to ensure your metal components meet exact specifications with superior quality and reliability. By partnering with us, you get expert advice on metal selection plus access to cutting-edge fabrication techniques that make your project stand out for performance and longevity.

Key Factors to Consider When Choosing a Metal

Picking the right metal for your custom fabrication project comes down to several important factors. Here’s what you should keep in mind:

Strength and Durability

Look for metals with the right tensile strength and hardness to handle the load and stresses your project will face. You want a metal tough enough to last but not overkill that adds unnecessary cost or weight.

Corrosion Resistance

If your project will be exposed to outdoor or harsh environments, corrosion resistance is a must. Metals like stainless steel or aluminum perform well in wet or salty conditions and help your parts stay strong over time.

Weight

Sometimes, weight matters—a lot. Lightweight metals like aluminum are great for parts where reducing weight improves performance, such as in aerospace or automotive projects. Heavy metals like steel offer extra strength but can add bulk.

Cost

You have a budget, and metal prices vary widely. It’s about balancing dollar signs with what you really need in durability and performance. Sometimes spending a bit more upfront saves money down the road on repairs or replacements.

Machinability and Weldability

Since many fabrication processes rely on CNC machining, laser cutting, and welding, choose metals that machines and welders handle easily. This reduces fabrication time and keeps costs down.

Aesthetic Appeal

For projects where looks matter—like architectural elements or decor—pick metals that take finishes well and have a clean visual impact. Stainless steel and brass often shine here.

Sustainability

If environmental impact is important, consider metals that are recyclable or have a smaller carbon footprint. Using sustainable materials supports green manufacturing and aligns with many US market values.

Choosing the right metal with these factors in mind ensures your custom fabrication project meets performance goals, stays within budget, and lasts as intended.

Top Metals for Custom Fabrication Projects

When it comes to the best metal for custom fabrication projects, here’s a quick look at popular choices and where they shine:

Aluminum

- Pros: Lightweight, corrosion-resistant, cost-effective, and easy to machine

- Cons: Not as strong as steel

- Best for: Aerospace, automotive, and consumer products

- HYCNC use: Precision CNC machining for detailed aluminum parts

Stainless Steel

- Pros: High corrosion resistance, very durable, visually appealing

- Cons: More expensive and heavier than aluminum

- Best for: Medical devices, food processing, architectural elements

- HYCNC use: Stainless steel fabrication for tough industrial parts

Carbon Steel

- Pros: Strong, affordable, versatile

- Cons: Can rust without proper finishing

- Best for: Structural components and industrial machinery

- HYCNC use: CNC cutting and forming for steel frameworks

Titanium

- Pros: Exceptional strength-to-weight ratio, corrosion-resistant

- Cons: Expensive and tricky to machine

- Best for: Aerospace, medical implants, high-performance uses

- HYCNC use: Specialized CNC processing for precision titanium parts

Copper and Brass

- Pros: Excellent conductivity, great for decorative use, corrosion-resistant

- Cons: Pricier and softer than steel

- Best for: Electrical components and decorative items

- HYCNC use: Precision CNC milling for intricate designs

No matter the metal, HYCNC helps match the right material to your project’s needs ensuring quality and performance.

Comparing Metals A Quick Reference Table

Here’s a quick look at how popular metals stack up for custom metal fabrication projects, focusing on key factors like strength, weight, cost, corrosion resistance, and machinability.

| Metal | Strength | Weight | Cost | Corrosion Resistance | Machinability |

|---|---|---|---|---|---|

| Aluminum | Moderate | Very Light | Low | High | Excellent |

| Stainless Steel | High | Heavy | High | Very High | Good |

| Carbon Steel | Very High | Heavy | Low | Low (needs finishing) | Moderate |

| Titanium | Very High | Light | Very High | Excellent | Challenging |

| Copper | Moderate | Heavy | High | Good | Good |

| Brass | Moderate | Heavy | High | Good | Excellent |

This table provides a simple way to compare metals based on what matters most for your project. For example, if you need lightweight and corrosion resistance on a budget, aluminum shines. For high strength and durability but higher cost, stainless steel or titanium might be best. Carbon steel offers great strength affordably but needs protection against rust. Copper and brass work well when conductivity or decorative appeal are priorities.

At HYCNC, we use these insights to help you pick the metal that fits your needs and your project’s demands for machinability and durability.

How to Choose the Best Metal for Your Project

Picking the right metal starts with clearly defining your project needs. Think about where the part will be used—is it indoors, outdoors, or in a harsh environment? What kind of load or stress will it need to handle? And of course, what’s your budget? These factors set the foundation for the best metal choice.

Next, talk with a CNC fabrication expert like HYCNC. Our team can help match metals to your specific requirements, balancing performance and cost. We also recommend testing prototypes early on. This way, you can see how the metal performs in real conditions before full production, saving time and money.

Don’t forget to consider finishing options. Powder coating and anodizing, for example, can boost corrosion resistance and improve the look of your parts, especially for outdoor or decorative projects.

At HYCNC, we offer personalized metal recommendations and prototyping services to make sure your project nails both function and style from the start. Let us help you find the best metal and process to fit your unique fabrication needs.

Common Mistakes to Avoid in Metal Selection

Choosing the wrong metal can cause big headaches down the road. Here are some common pitfalls to watch out for:

-

Ignoring environmental factors: Metals react differently to conditions like saltwater or humidity. Overlooking corrosion risks, especially in coastal areas, can lead to premature failure and costly repairs.

-

Prioritizing cost over performance: It’s tempting to pick the cheapest metal, but that often means sacrificing durability or functionality. Balancing budget with long-term performance is key.

-

Overlooking machinability: Some metals are harder to work with, which can increase fabrication time and costs. Ignoring this can cause delays and surprise expenses.

-

Skipping expert advice early on: Not consulting with a metal fabrication expert like HYCNC from the start can lead to poor material choices and design issues. Early input helps avoid costly mistakes and ensures the best metal matches your project needs.

Why Choose HYCNC for Your Custom Fabrication Project

When it comes to custom metal fabrication, HYCNC stands out with state-of-the-art CNC technology and a skilled team ready to handle your project from start to finish. Whether you need precision CNC machining, laser cutting, welding, or finishing services, we’ve got you covered with experience across various metals and industries.

Our experts work closely with you to choose the best metal and fabrication methods tailored to your project’s needs—ensuring quality, durability, and cost-effectiveness. One recent client needed a complex aluminum part for aerospace use. With our precision CNC machining and deep material knowledge, we delivered exactly what they required on time and within budget.

Ready to get started? Contact HYCNC today for a free consultation or quote, and let us help bring your custom fabrication project to life with the right metal and expert craftsmanship.

FAQs

What is the most cost-effective metal for custom fabrication?

Aluminum and carbon steel are usually the most budget-friendly options. Aluminum is lightweight and corrosion-resistant, while carbon steel offers great strength at a low price. Your choice depends on the project’s needs.

Which metal is best for outdoor fabrication projects?

Stainless steel and aluminum are top picks for outdoor use. Both resist rust and can handle harsh weather, making them ideal for coastal or outdoor environments.

How does HYCNC ensure quality in metal fabrication?

HYCNC uses state-of-the-art CNC machining, laser cutting, and welding equipment paired with skilled technicians. We follow strict quality checks at every step to guarantee precision and durability.

Can HYCNC handle small-scale or prototype fabrication projects?

Yes, we specialize in both small runs and prototypes. Our flexible CNC services are designed to meet tight deadlines and custom specs with high accuracy.

What finishing options does HYCNC offer for fabricated metals?

We provide various finishing options like powder coating, anodizing, polishing, and custom paint finishes—all tailored to boost your project’s durability and appearance.