What is a 3 Axis CNC Machine

Definition of a 3 Axis CNC Machine

A 3 axis CNC machine is a computer-controlled milling or cutting tool that operates along three primary axes: X, Y, and Z. This setup allows the machine to move a cutting tool left to right, front to back, and up and down, enabling precise shaping and machining of materials. It’s one of the most common types of CNC machining due to its versatility and reliability for a wide range of projects.

Key Components of a 3 Axis CNC Machine

- XYZ Axes: The three linear directions in which the tool or workpiece moves.

- Spindle: The rotating part holding the cutting tool, which removes material by spinning at variable speeds.

- Controller: The computer interface that runs CNC toolpath programming to direct all movements.

- Worktable: Fixed or movable stage where the material or workpiece is secured in place during machining.

- Tool Holder and Cutting Tools: Includes various end mills, drills, or ball nose cutters depending on the required operation.

Common Applications of 3 Axis CNC Machining

3 axis CNC machines are widely used in industries such as automotive, aerospace, and manufacturing for:

- Precision CNC milling of flat and moderately complex parts

- Cutting slots, pockets, and holes on metal, plastic, and wood

- Creating prototypes and small production runs with standard geometries

- Handling materials where slant angles and complex curves are limited or require specific techniques

The balance of simplicity and accuracy makes 3 axis CNC machining a foundational service, especially when paired with expert programming and tooling strategies. For detailed 3 axis CNC services, you can explore HYCNC’s 3 axis CNC machining offerings.

Can 3 Axis CNC Machines Cut Slant Angles

Capability of 3 Axis CNC Machines for Slant Angles

Yes, 3 axis CNC machines can cut slant angles, but with some caveats. They move the cutting tool in the X, Y, and Z directions, which lets them handle angled features by tilting the workpiece or using specific toolpaths. However, the tool itself doesn’t tilt, so the slant must be created through clever programming and setups.

Techniques to Cut Slant Angles on 3 Axis CNC

- Tilting the workpiece: Using custom fixtures to hold the part at the right angle so the cutter moves vertically but effectively creates a slant.

- Stepped cuts with Z-axis adjustment: Moving the tool gradually in the Z direction while cutting in X and Y to simulate a slope.

- Use of angled tooling: Sometimes, angled inserts or tools help extend the capability for slant cuts without tilting the part itself.

Limitations When Cutting Slant Angles on 3 Axis CNC

- Less flexibility compared to 5 axis machines: Since the tool orientation is fixed, complex slant angles can be challenging or require multiple setups.

- Higher chance of tool marks: Because the toolpath is limited, finishing on steep angles may show visible steps or marks.

- Longer setup and programming time: Achieving precise slants might take extra effort in holding and programming.

Practical Example of Slant Angle Cutting

Imagine cutting a simple tapered bracket. On a 3 axis CNC, you’d likely use a custom angled fixture and program the toolpath to gradually step down, creating the slant. While not as seamless as on a 5 axis, it gets the job done accurately for many straightforward applications like brackets, panels, or angled cuts on flat parts.

In short, 3 axis CNC machines handle slant angles well enough for many jobs, especially when paired with good fixturing and smart programming.

Can 3 Axis CNC Machines Cut Curves

Capability of 3 Axis CNC Machines for Curve Cutting

Yes, 3-axis CNC machines can cut curves, but with some considerations. These machines move the tool in the X, Y, and Z directions, allowing them to follow curved paths on flat or slightly contoured surfaces. This makes them suitable for CNC curve machining on many parts where complex 3D shapes aren’t required.

Techniques for Cutting Curves on 3 Axis CNC

To effectively machine curves on a 3-axis CNC:

- Use a ball nose endmill, which helps create smooth curved surfaces.

- Employ multi-pass toolpaths like contouring or parallel passes to gradually shape the curve.

- Optimize CNC toolpath programming to carefully control tool movement for better surface finish.

- Apply custom CNC fixtures to hold irregular parts securely during curve cutting.

Limitations of 3 Axis Curve Machining

While 3-axis machines can handle many curved features, they struggle with:

- Complex curves with deep undercuts or steep angles that need tool orientation beyond straight vertical or horizontal moves.

- Fine detail on highly contoured 3D shapes that require tilting or rotating the tool head.

- Surface finishing quality compared to multi-axis machines on intricate curves.

Practical Example

Imagine machining the rounded edges of a simple automotive bracket. A 3-axis CNC with a ball nose endmill can smoothly cut the curved profiles by following a programmed contour toolpath. However, if the design has intricate, angled surfaces, you’d hit the limits of 3-axis machining.

For more insight on handling complex curves, consider how multi-axis machines compare at Why 5 Axis CNC for Complex Parts.

For detailed 3-axis CNC machining options and services, visit our 3 Axis CNC Machining page.

Comparing 3 Axis vs 5 Axis CNC Machines for Slant Angles and Curves

Key Differences in CNC Slant Angle Cutting and Curve Machining

3 axis CNC machines move a cutting tool along the X, Y, and Z axes. This setup works well for flat or simple angled surfaces but struggles with complex slant angles and flowing curves because the tool can only approach from one direction at a time. On the other hand, 5 axis CNC machines add two more rotational axes, allowing the tool to tilt and rotate for much more precise and flexible cutting of slant angles and curves. This means they can handle intricate parts and uneven surfaces with far better accuracy and finish.

When to Use 3 Axis CNC Machines

Choose a 3 axis machine if your projects involve:

- Mostly flat or simple angled cuts

- Basic curves and rounded features

- Lower complexity parts that don’t require multi-axis tool movements

- Tight budgets or faster setup times

- Jobs where precision curve machining can be achieved with clever programming and toolpath planning

When to Use 5 Axis CNC Machines

5 axis machines are better when you need:

- Complex slant angles that require the tool to tilt and rotate

- Smooth, intricate curves that a 3 axis can’t easily reach

- Reduced part setups thanks to multi-axis capability

- High precision machining with fewer tool changes

- Reduced manual finishing and higher surface quality

If your project demands advanced precision or complex geometries, check out our detailed insights on 5 axis machining here.

Cost Considerations

3 axis CNC machining generally costs less upfront and has simpler programming, making it ideal for smaller shops and less complex parts. The tooling and maintenance budget here are lower as well.

5 axis CNC machines are more expensive to buy and require skilled operators, but they can save time and money on complex jobs by reducing the need for multiple setups and extensive manual work. For businesses looking to grow their capabilities in complex machining, investing in 5 axis might be worthwhile.

HYCNC Expertise in 3 and 5 Axis CNC Machining

At HYCNC, we understand when to leverage the strengths of both 3 axis and 5 axis CNC machining to deliver precise, cost-effective results. Our team offers:

- Advanced CNC toolpath programming tailored to your part’s geometry

- Expert advice on whether your project fits 3 axis or 5 axis machining best

- Custom CNC fixtures and setups to optimize cutting angles and curves

- Access to a wide range of state-of-the-art equipment

We’re ready to help you get the best balance between precision, cost, and speed for your manufacturing needs. Check out our full range of CNC services 3 axis CNC machining and 5 axis CNC machining to learn more.

Tips for Optimizing 3 Axis CNC Machining for Slant Angles and Curves

Optimizing your 3-axis CNC machining for slant angles and curves can make a big difference in quality and efficiency. Here’s how we at HYCNC approach it, focusing on what really works for U.S. customers needing precise, reliable results.

Tool Selection for CNC Slant Angle Cutting and Curve Machining

- Use ball nose endmills: These are great for smooth curves and gentle slants, giving you better surface finish on complex shapes.

- Choose the right tool size: Smaller tools can handle tighter curves but may slow down production. Bigger tools cut faster but might miss finer details.

- High-quality carbide tools: Durable and sharp tools keep cuts clean, especially important for slant angles where tool deflection can be an issue.

Workholding Solutions for Precision CNC Milling

- Custom CNC fixtures: Secure your workpiece firmly to prevent movement during cutting, ensuring better accuracy on angled surfaces.

- Adjustable vises and clamps: These help position parts at the best orientation for 3-axis machining of slants and curves.

- Use soft jaws or padding when working with delicate materials so you avoid marks or deformation during clamping.

Programming Best Practices for CNC Toolpath Programming

- Optimize toolpaths for efficiency and smoothness: Use software features that create continuous, flowing paths for curve machining instead of sharp starts and stops.

- Use multi-step finishing passes: Rough cuts remove bulk material, while finishing passes refine slants and curves for precision.

- Strategic tool lead-ins and lead-outs: Reduce marks and improve surface finish by programming smooth entries and exits on curves and angled cuts.

Material Considerations for 3 Axis vs 5 Axis Machining

- Softer materials like aluminum or plastics are easier to machine on 3-axis when working on slant angles and curves.

- Harder metals may require slower feeds or more tooling passes to avoid tool wear or heat buildup.

- Some materials react better to specific tool coatings or coolant strategies to maintain quality in complex cuts.

HYCNC Approach to 3 Axis CNC Machining for Slant Angles and Curves

At HYCNC, we combine state-of-the-art CAD/CAM software with years of experience in precision CNC milling to get the best from 3-axis machines. We focus on:

- Custom CNC fixtures tailored to your parts for reliable workholding.

- Toolpath strategies designed around the unique shape and slant angle of your parts.

- Material expertise to pick the right tools and feeds for every job, saving time and cost.

- Close communication with you to tweak the process until it fits your exact needs.

By dialing in these factors, we help U.S. manufacturers and designers get the most out of 3-axis CNC machining, even for slant angles and curves where precision counts.

Why Choose HYCNC for Your 3 Axis CNC Machining Needs

At HYCNC, we understand the unique demands of 3-axis CNC machining for cutting slant angles and curves. Here’s why we’re the right partner for your CNC projects:

Expertise in Precision CNC Milling

Our team brings years of experience working with a range of materials and complex geometries. Whether you need CNC slant angle cutting or CNC curve machining, we have the know-how to deliver precise and reliable results every time. We focus on quality and accuracy, ensuring your parts meet exact specifications.

Custom Solutions Tailored to Your Needs

No two projects are the same. That’s why HYCNC offers custom CNC fixtures and tailored programming to optimize your 3-axis machining jobs. We use smart CNC toolpath programming strategies to get the most out of 3-axis capabilities, balancing efficiency and precision.

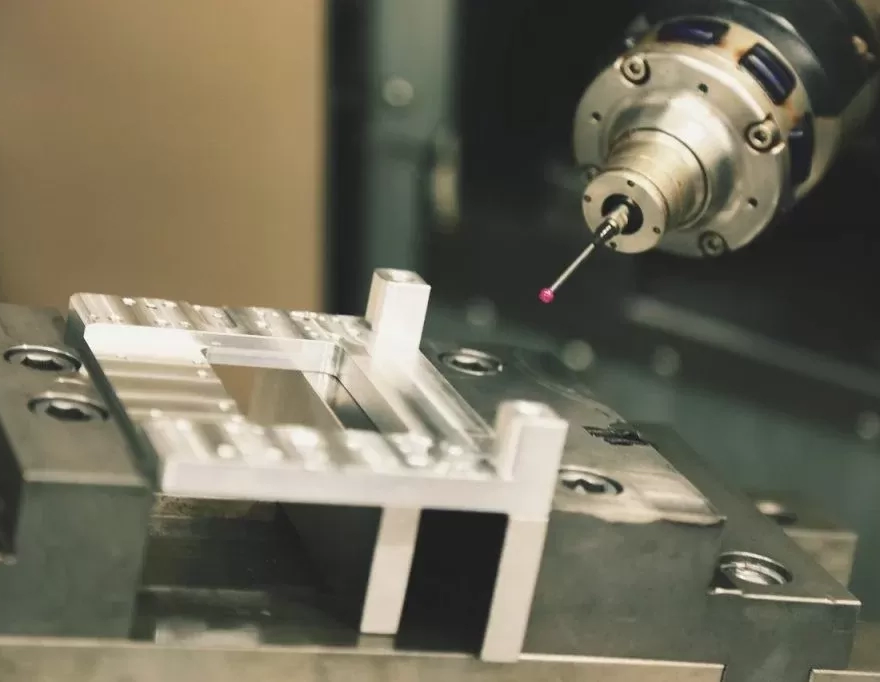

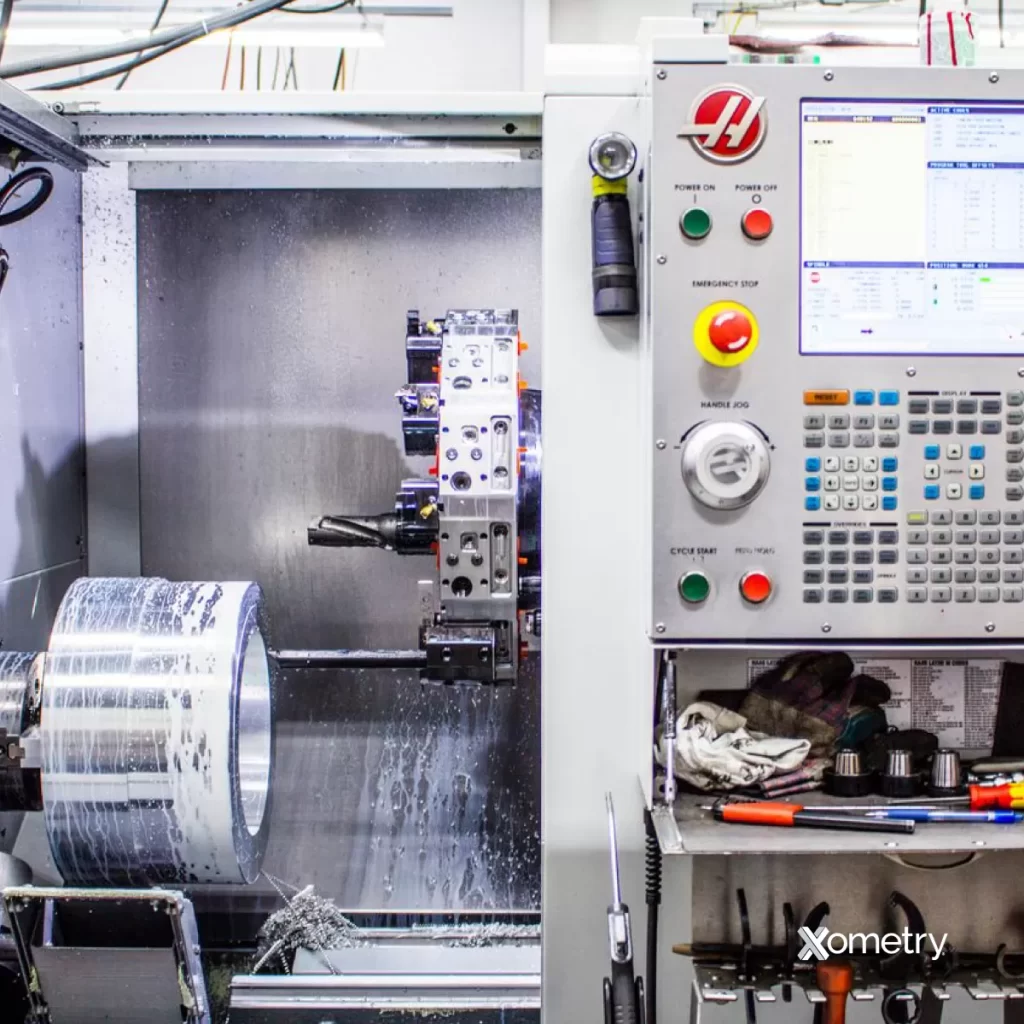

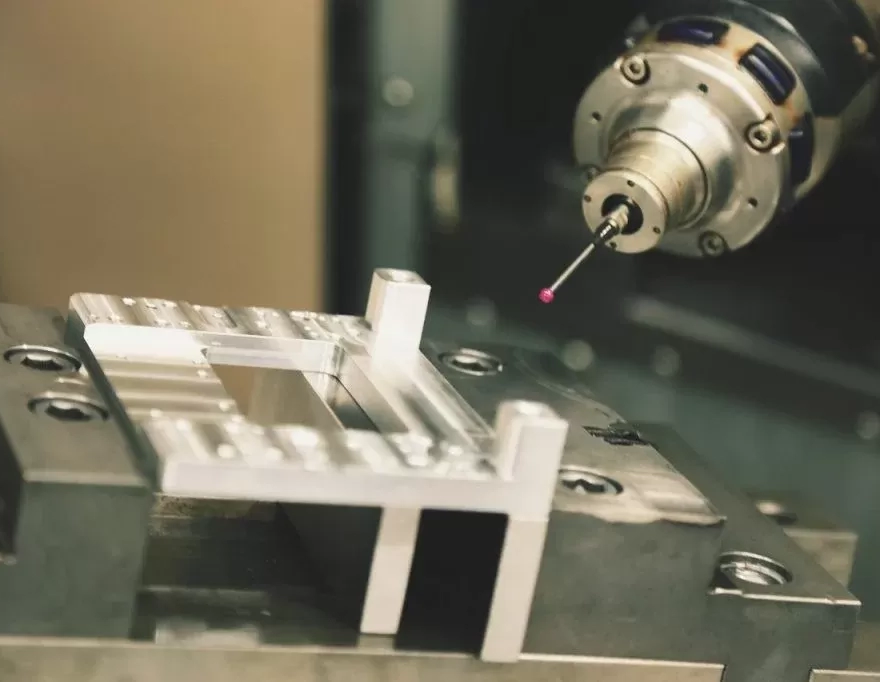

State of the Art Equipment

We invest in the latest CNC machines and tooling to support a wide range of applications. Our advanced machining centers and tooling options—including ball nose endmills for smooth curves—allow us to handle complex shapes and slant angles within the limits of 3-axis machines.

Ready to Take Your Project Further

Looking to get started or optimize your CNC machining workflow? Reach out to us for expert guidance and service you can trust. Whether your parts call for simple cuts or more involved shapes, HYCNC is your go-to resource for dependable 3-axis CNC machining services.

Explore how we can help at our 3-axis CNC machining page and get a custom quote today. Let’s make your project happen with precision and confidence.