Custom Metal Prototypes

Custom metal prototypes play a vital role in driving innovation across industries. They provide engineers, designers, and business owners with the opportunity to test ideas early, refine designs, and overcome manufacturing challenges before moving to full production. By creating precise, functional prototype parts using metals like aluminum, titanium, and steel, innovators can explore new concepts with confidence and speed.

Importance of Prototyping in Product Development

Prototyping is an essential step in the product development cycle. It allows teams to:

- Validate design functionality and identify potential flaws

- Assess fit, form, and function in real-world conditions

- Reduce costly mistakes during mass manufacturing

- Accelerate time-to-market with rapid metal prototyping

- Improve communication among stakeholders through tangible models

Without prototypes, product ideas remain theoretical, increasing risks and delaying innovation.

Benefits of Metal Prototypes

Metal prototypes bring distinct advantages over plastic or other materials:

- Superior strength and durability, mimicking end-use conditions

- Ability to test metal-specific properties like thermal resistance and wear

- Precision that supports complex geometries and tight tolerances

- Compatibility with custom CNC parts and advanced manufacturing processes

These benefits make metal prototypes indispensable for industries demanding high performance, such as aerospace, medical devices, automotive, and defense.

Innovation-Driven Applications of Metal Prototypes

Custom metal prototypes are empowering innovation in diverse, high-impact sectors by enabling:

- New product development in cutting-edge technologies

- Functional testing under real operating stresses

- Low-volume metal production runs for market validation

- Design optimization through iterative rapid prototyping

- Faster commercialization of breakthrough ideas

By leveraging custom metal prototyping, companies can stay competitive, reduce development costs, and bring innovative solutions to market faster than ever before.

HYCNC’s Custom Metal Prototyping Services for Innovation

Overview of HYCNC’s Capabilities in Metal Prototyping

At HYCNC, we specialize in custom metal prototypes that help innovators turn ideas into reality. Our advanced CNC machining services, metal 3D printing (DMLS), and sheet metal fabrication cover a wide range of materials like aluminum, titanium, and stainless steel. Whether you need precision prototyping or low-volume metal production, we deliver fast, reliable results tailored to your project’s needs.

Why Choose HYCNC for Your Custom Metal Prototypes

- Quality you can trust: We use cutting-edge equipment and maintain tight quality controls to ensure every prototype meets strict standards.

- Rapid turnaround times: Speed matters in innovation; our streamlined process keeps your project moving from design to prototype quickly.

- Experienced team: Our experts understand the unique challenges of metal prototyping and work closely with you to solve them.

- Flexible production options: From complex custom CNC parts to quick sheet metal runs, we adapt to fit your innovation cycle and budget.

Tailored Solutions for Innovators Across Industries

We don’t just make parts—we provide custom solutions that accelerate product development. Whether you’re testing new concepts or preparing for small-batch production, HYCNC supports innovation in sectors like aerospace, medical devices, automotive, and industrial equipment. Our approach ensures your prototypes reflect real-world use and help refine your design before full-scale manufacturing.

Choose HYCNC for a metal prototyping partner that understands innovation drives success.

Prototyping Technologies for Innovation with Custom Metal Prototypes

When it comes to bringing new ideas to life, having the right prototyping technology makes all the difference. At the heart of custom metal prototypes for innovation are several proven methods that deliver precision, speed, and reliability.

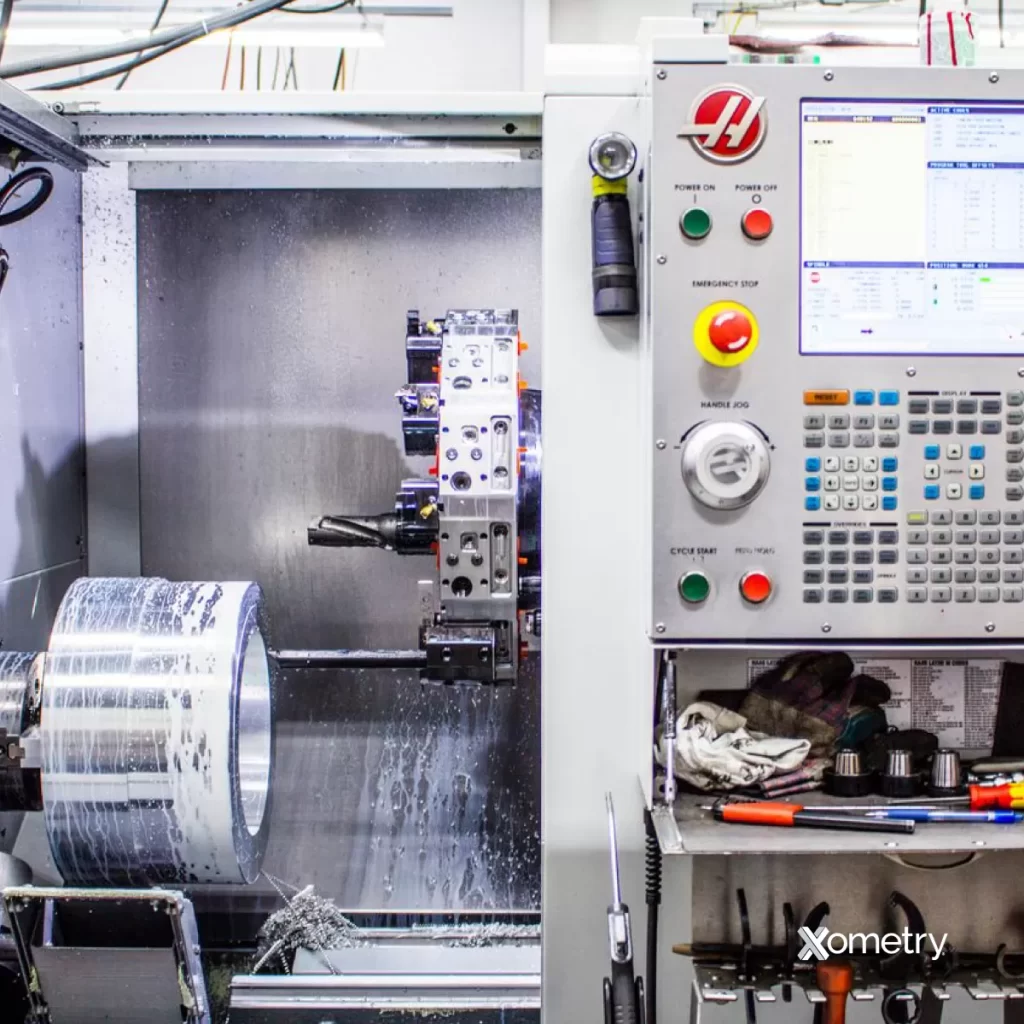

CNC Machining for Precision Prototyping

CNC machining services are a go-to for precision prototyping. Using computer-controlled tools, CNC machining can produce complex custom CNC parts with tight tolerances from metals like aluminum and titanium. This method is excellent for both one-off prototypes and low-volume metal production, ensuring your design feels and functions like the final product.

Metal 3D Printing DMLS for Complex Designs

Direct Metal Laser Sintering (DMLS) is a standout among metal 3D printing options. It builds parts layer by layer straight from metal powders, opening up possibilities for intricate shapes that traditional machining can’t handle easily. DMLS works great with tough metals and is perfect when innovation demands highly detailed prototypes or rapid iterations.

Sheet Metal Fabrication for Structural Prototypes

Sheet metal fabrication focuses on bending, cutting, and assembling thin metal sheets. It’s ideal when you need prototypes that represent the look and ruggedness of your final product, often used in housings, brackets, and enclosures. This technique supports quick turnaround and cost-effective options for innovation-driven projects.

Other Methods Briefly

- Casting and Forging: Great for simulating final production parts but with longer lead times.

- Waterjet Cutting: Precision cutting for thick or delicate metals without heat distortion.

- EDM (Electrical Discharge Machining): Ideal for detailed cuts on hard metals.

Each of these technologies supports innovation in different ways, giving you flexibility depending on your design needs, materials, and speed requirements. Using a combination of these prototyping techniques, especially with rapid metal prototyping capabilities, helps innovators test, refine, and bring products to market successfully.

How HYCNC Drives Innovation Through Custom Metal Prototyping

When it comes to custom metal prototypes for innovation, HYCNC stands out by offering a streamlined prototyping process designed to get your ideas from concept to reality fast and with precision. We know time is money, especially in product development, so our workflow focuses on minimizing delays while maximizing quality.

Streamlined Process for Precision Prototyping

At HYCNC, every step is optimized for efficiency. From initial design review to rapid metal prototyping using CNC machining or metal 3D printing, we keep communication clear and timelines tight. This allows us to deliver precision prototyping on aluminum, titanium, and other metals with the accuracy innovators demand.

Real-World Success Stories That Show Results

Our track record speaks volumes. We’ve helped startups and established manufacturers alike bring cutting-edge products to market faster by providing custom CNC parts and low-volume metal production that fit their exact specs. One client improved their product testing phase by 30% thanks to our fast turnaround on titanium prototypes.

Customer-Centric Approach Tailored to Innovators

We don’t just make metal parts; we partner with you. Every project gets personal attention, ensuring your unique innovation goals are met. Whether you need sheet metal fabrication or direct metal laser sintering (DMLS) for complex geometries, our team adapts to your needs — helping you solve problems before they even arise.

In short, HYCNC’s focus on speed, precision, and customer collaboration makes it a top choice for anyone serious about developing custom metal prototypes for innovation.

Tips for Choosing a Custom Metal Prototyping Partner for Innovation

Finding the right prototyping partner is critical when you’re focused on custom metal prototypes for innovation. The right provider helps turn your ideas into reality quickly and accurately. Here are some key factors to consider when choosing a partner like HYCNC.

Key Factors to Consider

-

Experience with Rapid Metal Prototyping

Look for a partner skilled in various rapid prototyping techniques such as CNC machining services, metal 3D printing, and sheet metal fabrication. This flexibility ensures your design can be realized no matter the complexity.

-

Precision and Quality Control

Precision matters in innovation. Opt for providers who offer tight tolerances and reliable quality checks throughout the process to deliver accurate custom CNC parts.

-

Material Expertise

Your project might need specific metals like aluminum or titanium. Choose a partner experienced with these materials to ensure durability and performance.

-

Turnaround Time and Scalability

Innovation moves fast. A prototyping partner that offers fast turnaround and the ability to handle low-volume metal production is a big plus.

-

Communication and Collaboration

Clear and ongoing communication ensures the prototype aligns with your specifications. The best partners stay engaged throughout the project.

Questions to Ask Providers

Before committing, ask these crucial questions:

- What prototyping technologies do you use? (CNC machining, DMLS metal 3D printing, etc.)

- Can you handle prototypes in different metals like titanium or aluminum?

- How do you maintain quality and precision in your custom metal prototypes?

- What is the typical lead time for producing prototypes?

- Do you offer design feedback or support during prototyping?

- Can you scale from prototype to low-volume production?

Why HYCNC Stands Out

At HYCNC, we understand what drives your innovation. Here’s why we’re a top choice:

- Diverse Prototyping Capabilities including advanced CNC machining, metal 3D printing (DMLS), and sheet metal fabrication make us a one-stop shop.

- Material Flexibility letting you prototype in aluminum, titanium, and more with experts guiding your choices.

- Fast and Reliable Service designed for rapid metal prototyping needs without sacrificing precision.

- Customer-Focused Approach means we work closely with you from start to finish.

- Proven Track Record through real-world success stories supporting innovations across industries.

Choosing HYCNC means partnering with a team that values precision, speed, and flexibility—everything needed to bring your custom metal prototype ideas to life swiftly in the United States market.

FAQs About Custom Metal Prototypes for Innovation

What are custom metal prototypes and why are they important for innovation

Custom metal prototypes are early models of a product made from metals like aluminum or titanium. They let you test design, fit, and function before full production. This speeds up innovation by catching issues early and making improvements faster.

Which prototyping technologies does HYCNC offer

HYCNC uses CNC machining, metal 3D printing (DMLS), and sheet metal fabrication to create precision prototypes. These methods ensure accurate, high-quality custom CNC parts tailored to your project needs.

How fast can I get my prototype from HYCNC

HYCNC specializes in rapid metal prototyping with a streamlined process designed for quick turnaround without sacrificing quality. Typical delivery times depend on the complexity but are competitive for low-volume metal production.

Can you work with specific metals like titanium or aluminum

Yes, HYCNC works with a variety of metals including aluminum prototypes and titanium prototyping. This flexibility supports innovation across industries requiring different material properties.

Do you support low-volume runs or only large production

HYCNC focuses on low-volume metal production, ideal for prototyping and small batch runs. This fits innovators who need precise parts quickly without large upfront costs.

What makes HYCNC different from other CNC machining services

- Customer-centric approach that adapts to your innovation goals

- Wide range of prototyping technologies for flexibility

- Expertise in precision and quality for complex designs

- Fast, reliable communication tailored to US customers

How do I choose the right prototyping partner

Look for:

- Proven experience with custom metal prototypes

- Access to multiple prototyping technologies

- Quick turnaround and clear communication

- Flexibility for low-volume runs

- Positive customer feedback

HYCNC ticks all these boxes, making it a solid choice for innovation-driven projects.

If you have more questions or want to discuss your project, reach out to HYCNC to get expert advice on your custom metal prototyping needs.