Are you wondering why waterjet cutting is the go-to choice for precision fabrication? Choosing the right cutting technology can make or break your project’s success, from flawless finishes to cost savings.

As a CNC expert at HYCNC, I’ve seen firsthand how waterjet cutting transforms ideas into reality with unmatched accuracy and versatility. This guide unlocks the the benefits of waterjet cutting, revealing why it’s a game-changer for industries like aerospace, automotive, and beyond.

In this article, you’ll discover how waterjet cutting delivers precision, eco-friendliness, and efficiency—and why HYCNC’s advanced CNC waterjet services are your key to top-tier results.

Let’s dive in!

What Is Waterjet Cutting

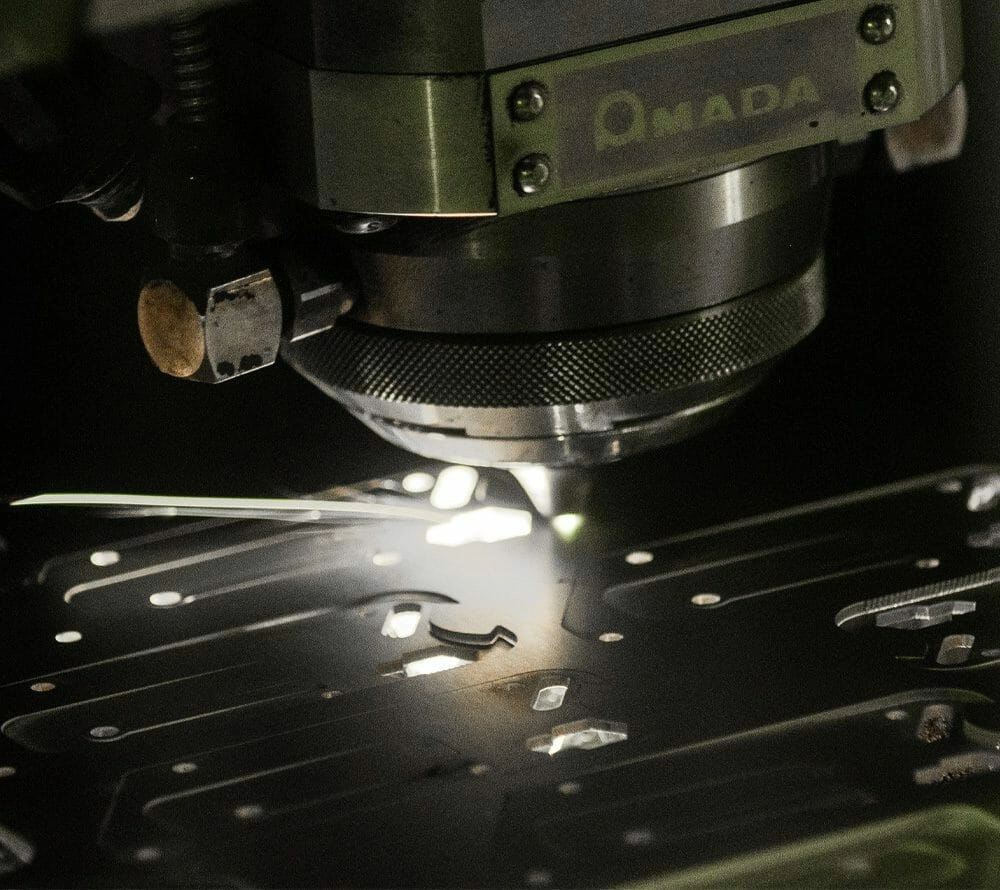

Waterjet cutting is a cold-cutting process that uses a powerful stream of high-pressure water to cut a variety of materials. Often, abrasives like garnet are added to the waterjet stream to enhance its ability to slice through tougher materials such as metals, stone, composites, and glass. Because waterjet cutting does not generate heat, it preserves the material’s natural properties, making it ideal for heat-sensitive applications.

Evolution of Waterjet Cutting Technology

This precision cutting technology dates back to the 1950s, starting with basic water erosion techniques. Over the decades, it has advanced significantly, moving from simple machines to sophisticated systems capable of five-axis cutting. Modern waterjet machines allow complex shapes and intricate designs with exceptional accuracy and minimal material waste. This evolution has made waterjet cutting a favored method in industries requiring exacting standards like aerospace, automotive, and marine.

How HYCNC Utilizes Advanced Waterjet Cutting

At HYCNC, we leverage the latest in CNC waterjet cutting services, including state-of-the-art 5-axis technology, to deliver unmatched precision and quality. Our processes are tailored to meet the unique demands of diverse industries, ensuring smooth, burr-free edges and tight tolerances. With our expertise, we push the boundaries of material versatility while maintaining efficiency and eco-friendly practices. This commitment makes HYCNC a trusted partner for manufacturing projects that demand precision and reliability.

For more insights on precision cutting and how it compares with other methods, check out our detailed comparison of waterjet cutting vs laser cutting.

Key Benefits of Waterjet Cutting

Unmatched Precision and Accuracy

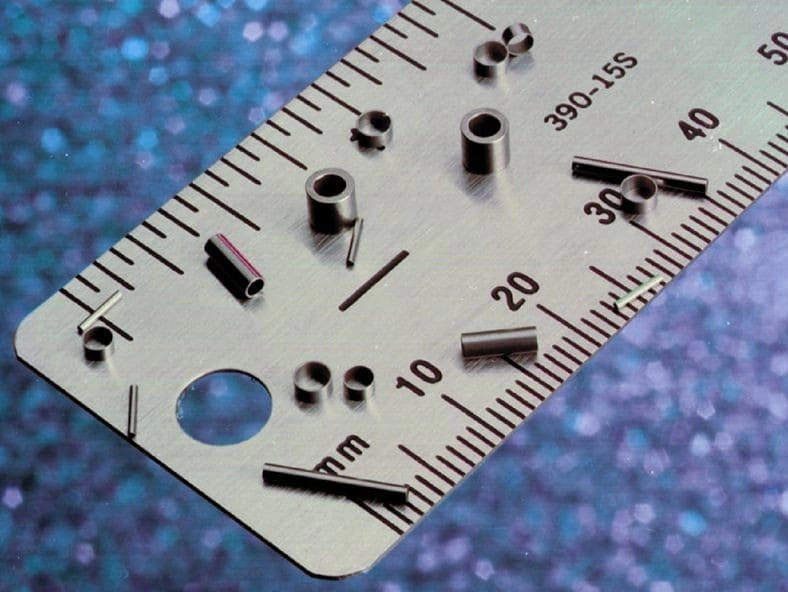

Waterjet cutting offers tight tolerances as precise as ±0.03 inches, making it perfect for detailed, intricate designs—especially in demanding fields like aerospace. At HYCNC, we deliver smooth, burr-free edges, which means less time and money spent on secondary finishing.

Versatility Across Materials

One of the biggest advantages of waterjet cutting is its ability to cut through a wide range of materials including metals like titanium and stainless steel, composites, carbon fiber, glass, stone, and more. This versatility allows HYCNC to serve various industries such as automotive and marine with tailored precision cutting solutions.

No Heat-Affected Zones

Because waterjet cutting is a cold cutting process, it avoids heat-related problems like thermal distortion, warping, or changes to material properties. This makes it ideal for heat-sensitive materials like composites and plastics, keeping their integrity intact.

Environmentally Friendly Process

Waterjet cutting creates minimal waste and uses recyclable water and abrasives like garnet, making it one of the most eco-friendly cutting methods available. HYCNC is committed to sustainable manufacturing practices, reducing environmental impact without compromising quality.

Cost-Effectiveness and Efficiency

This method lowers costs by reducing the need for special tooling, fixturing, and post-processing. At HYCNC, we optimize productivity by stacking multiple layers for simultaneous cutting, speeding up projects without sacrificing accuracy.

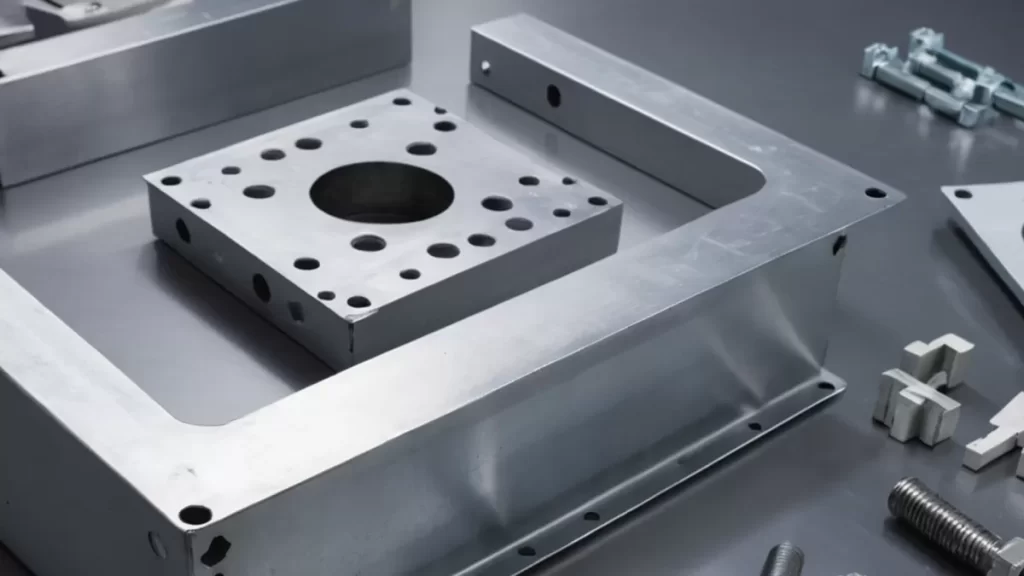

Handles Complex Shapes and Thick Materials

Waterjet cutting is capable of handling intricate curves and complex shapes, even in materials up to 8 inches thick. With our state-of-the-art 5-axis waterjet systems, HYCNC can achieve advanced geometries that meet the most demanding specifications.

Applications of Waterjet Cutting in Key Industries

Waterjet cutting is a go-to precision cutting technology for many industries across the U.S. Its versatility and clean, cold-cutting process make it ideal where quality and detail matter.

Industries Benefiting from Waterjet Cutting

- Aerospace: Waterjet cutting excels at handling advanced materials like carbon fiber and titanium used in aircraft parts, ensuring tight tolerances without heat damage.

- Automotive: Cuts stainless steel, aluminum, and composites for parts that require exact shapes and smooth edges.

- Marine: Ideal for cutting thick metals and composites used in boat hulls and marine fittings.

- Textiles and Art: Creates intricate designs on fabrics and glass, allowing for creative freedom with minimal waste.

Specific Material Examples

- Cutting carbon fiber sheets cleanly for aerospace structural components.

- Precision slicing of stainless steel panels used in automotive frames and decorative parts.

- Shaping glass panels and decorative elements for architectural applications without cracking or chipping.

Customized Waterjet Cutting Solutions by HYCNC

At HYCNC, we tailor abrasive waterjet cutting services to meet the exact needs of local and global clients. Whether it’s a small batch or a large production run, we leverage our 5-axis waterjet cutting technology and CNC machining expertise to:

- Deliver accurate cuts on complex geometries.

- Handle a wide range of materials with precision.

- Ensure fast turnaround times without compromising quality.

Our approach aligns with the demands of industries requiring reliable, cost-effective, and eco-friendly fabrication methods—making HYCNC a trusted partner for waterjet cutting projects nationwide.

Waterjet Cutting vs Other Cutting Methods

When deciding on the best cutting method for your project, it helps to compare waterjet cutting advantages against laser, plasma, and EDM methods. Here’s a quick look at how they stack up in terms of precision, material versatility, heat impact, and cost.

| Cutting Method | Precision | Material Versatility | Heat Impact | Speed | Cost |

|---|---|---|---|---|---|

| Waterjet Cutting | High – tight tolerances | Extremely versatile – metals, composites, stone, glass | No heat-affected zones (HAZ) – cold cutting process | Moderate – slower on thick materials | Moderate initial cost, efficient long-term |

| Laser Cutting | High for thin materials | Limited by material thickness and heat sensitivity | Creates heat-affected zones, can warp some materials | Fast for thin parts | Moderate, less with thin sheets |

| Plasma Cutting | Moderate precision | Good for metals | Produces heat-affected zones, warping possible | Faster on thick metals | Lower upfront cost |

| EDM Cutting | Very high precision | Only conductive metals | No heat distortion but very slow process | Slowest | High operational cost |

Why HYCNC’s Waterjet Cutting Stands Out

At HYCNC, we leverage advanced CNC waterjet services that deliver high precision and handle a wide range of materials without any heat damage. This makes our waterjet cutting an ideal choice for projects needing complex shapes, especially in industries like aerospace, automotive, and marine where material integrity matters.

- No heat-affected zones mean parts keep original strength and finish.

- Capable of cutting thick, multi-layered materials that lasers struggle with.

- Combines precision with versatility for both prototyping and high-volume production.

- Our 5-axis waterjet cutting system precisely tackles intricate geometries others can’t.

Choosing waterjet over laser, plasma, or EDM at HYCNC means getting a reliable, eco-friendly, and cost-effective fabrication method that’s perfect for demanding projects. For more on how different cutting methods compare, check out our blog post on EDM vs Laser vs Waterjet vs Plasma CNC cutting.

Why Choose HYCNC for Waterjet Cutting Services

When it comes to waterjet cutting, HYCNC stands out with state-of-the-art equipment and advanced CNC technology. This combination ensures every cut is precise, consistent, and meets tight tolerances—perfect for projects that demand accuracy. Whether you need a small batch or a large-scale production run, we tailor our services to fit your specific needs, giving you flexibility and control over your project.

Our team brings local expertise with a global reach, serving industries across the United States and beyond. From aerospace to automotive and marine, we understand the unique challenges each sector faces and provide solutions that deliver results.

We know time is money, so we focus on fast turnaround times without cutting corners. Alongside competitive pricing, HYCNC is committed to eco-friendly cutting methods, making us a reliable choice for customers who care about sustainable manufacturing.

Ready to experience the benefits of precision waterjet cutting? Contact HYCNC today for a quote or consultation and let’s bring your project to life with quality you can count on.

Limitations of Waterjet Cutting and How HYCNC Addresses Them

While waterjet cutting offers many advantages, there are some limitations to keep in mind:

- Slower cutting speeds on thick materials compared to laser cutting, especially for metals over a few inches thick.

- Higher initial equipment costs due to advanced CNC waterjet machinery.

- Abrasive material expenses, like garnet, add to operating costs.

At HYCNC, we understand these challenges and have developed ways to maximize efficiency and control costs:

- Using optimized cutting paths and layering techniques to speed up jobs without sacrificing quality.

- Leveraging our expert CNC programming and machine expertise to reduce abrasive use while maintaining precision.

- Offering tailored solutions that balance material type, thickness, and budget to deliver the best value for both small and large production runs.

By focusing on smart process management and skilled operation, HYCNC helps customers get the most out of waterjet cutting, making it a cost-effective and precise choice for various industries here in the U.S.