Understanding Electrical Safety and Efficiency

Are you confident that your electrical systems are both safe and efficient? Understanding the basics of electrical safety and efficiency is crucial for protecting people, reducing costs, and keeping operations running smoothly.

Defining Electrical Safety

Electrical safety means protecting workers and equipment from hazards like:

- Electric shocks that can cause injury or death

- Arc flashes, which produce intense heat and light, risking burns and blindness

- Electrical fires that can destroy property and halt operations

These hazards don’t just threaten personnel—they can also cause costly downtime, damage equipment, and disrupt productivity.

Defining Electrical Efficiency

Efficiency in electrical systems focuses on:

- Minimizing energy loss during power transmission and use

- Reducing downtime caused by system failures or maintenance

- Lowering maintenance costs by designing reliable, long-lasting systems

This approach helps you save money and boosts overall operational performance.

Why Safety and Efficiency Matter

Safety and efficiency aren’t just good practices—they’re essential for:

- Meeting regulatory compliance, such as OSHA and NFPA 70E standards

- Cutting operational costs with fewer accidents and less wasted energy

- Increasing productivity by keeping systems reliable and employees safe

When you prioritize safety and efficiency together, you create a workplace that’s safer, smarter, and more cost-effective.

Key Standards and Regulations for Electrical Safety

Understanding and following key electrical safety standards is crucial to protect people and keep systems running smoothly. Globally, organizations like OSHA, NFPA 70E, IEC 60364, and ISO 45001 set important guidelines. OSHA focuses on workplace safety in the U.S., while NFPA 70E specifically addresses electrical safety standards to prevent injuries from shocks and arc flashes. IEC 60364 covers electrical installations internationally, and ISO 45001 deals with overall occupational health and safety management.

In the United States, OSHA regulations and the National Electrical Code (NEC) play a major role in setting the bar for safety and compliance. In Europe, IEC standards guide electrical safety and system design. Different regions have their own specific rules, but the goal remains the same: protecting workers and equipment while maintaining reliable electrical systems.

Sticking to these standards helps reduce the risk of accidents, lowers downtime, and improves system reliability. Compliance is more than just a legal requirement—it’s a practical step that saves money and keeps your operations efficient and safe.

Best Practices for Ensuring Electrical Safety

Keeping electrical systems safe starts with following solid daily practices. Here’s what works:

Conduct Regular Inspections

- Check wiring, connections, and grounding frequently.

- Look for signs of wear, corrosion, or damage.

- Inspect equipment condition to catch issues early and avoid downtime.

Implement Lockout Tagout (LOTO)

- Always follow LOTO procedures before maintenance.

- Ensure power sources are fully de-energized and locked to prevent accidental startup.

- Train staff on proper LOTO steps to keep everyone protected.

Use Personal Protective Equipment (PPE)

- Wear insulated gloves and use insulated tools whenever working on live or potentially live circuits.

- Use arc-flash-rated clothing and face protection to guard against sparks and burns.

- PPE reduces risk and is required under OSHA and NFPA 70E standards.

Perform Risk Assessments

- Identify potential electrical hazards on-site.

- Assess how severe each risk is and prioritize fixes accordingly.

- Use NFPA 70E guidelines to help evaluate and mitigate risks effectively.

Following these best practices helps reduce workplace electrical hazards and keeps your systems reliable and safe for the team.

Strategies for Enhancing Electrical System Efficiency

To boost electrical system efficiency, start with load analysis and power distribution. Properly balancing the load helps reduce energy waste, prevents excessive wear, and cuts down on downtime. Make sure power is distributed evenly across systems to avoid overloads that can lead to costly repairs or interruptions.

Next, take advantage of automation and smart technologies. Using IoT devices and AI-driven monitoring lets you catch issues early and plan maintenance before failures happen. These tools provide real-time data, helping you make smarter decisions and keep systems running smoothly.

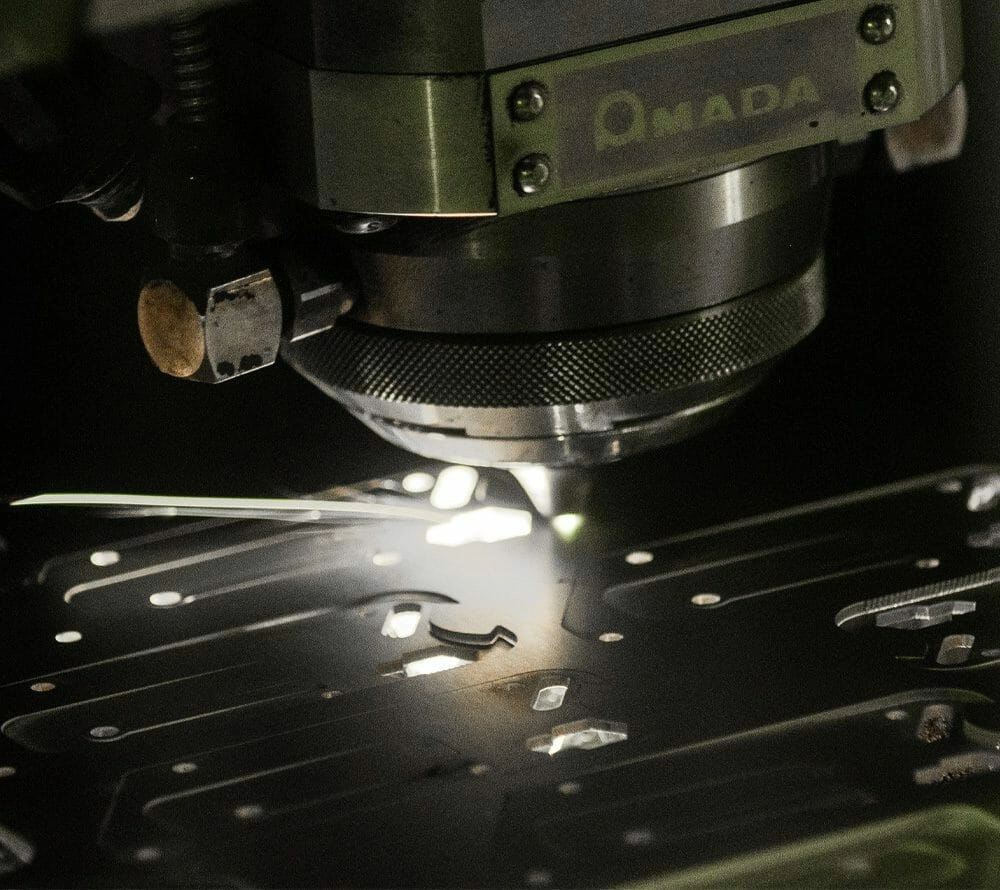

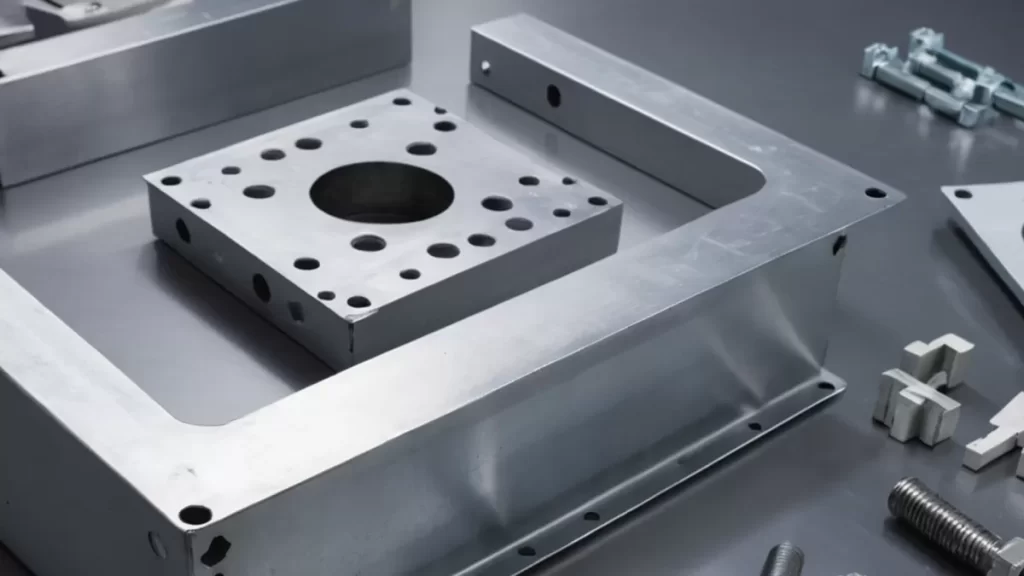

Another key factor is using precision components, like high-quality CNC-machined electrical parts. These parts fit better, last longer, and minimize failures that disrupt operations. Precision manufacturing ensures your system is reliable and runs at peak performance.

Finally, implement energy management systems to track and optimize energy use. Digital platforms can monitor consumption patterns, suggest efficiencies, and lower overall costs. This approach not only saves money but also supports sustainability goals.

Together, these strategies create a smarter, safer, and more efficient electrical system designed to meet the demands of today’s US market.

Leveraging Technology for Safety and Efficiency

Technology is a game-changer when it comes to ensuring safety and efficiency in electrical systems. Here’s how modern tools make a real difference:

IoT and Real-Time Monitoring

IoT devices keep an eye on electrical systems around the clock. They spot faults early, like unusual heat or voltage drops, before these issues turn into serious problems. This real-time monitoring helps avoid unexpected downtime and improves overall safety.

AI-Driven Risk Assessments

Artificial intelligence analyzes large amounts of data from your electrical setup. It predicts when maintenance is needed or when a component might fail. This proactive approach cuts down on emergency repairs and keeps your system running smoothly and safely.

Automation in Design and Testing

Automated tools streamline design layouts and testing processes, ensuring precision and consistency. This reduces human error, helping maintain high safety standards and efficient performance throughout the electrical system lifecycle.

HYCNC’s Role in Enhancing Safety and Efficiency

At HYCNC, precision CNC machining makes a big difference. By producing high-quality, precisely engineered electrical components, we reduce the risk of equipment failure. Better parts mean safer systems and greater efficiency, which leads to fewer costly interruptions and improved compliance with industry safety standards.

Case Studies and Real-World Applications

Manufacturing Facility

In a busy manufacturing plant, regular electrical inspections helped catch wiring issues before they caused problems. Pairing these checks with precision electrical components made with CNC machining significantly cut downtime. The result? Smoother operations, fewer unexpected repairs, and better overall safety for their team.

Data Center

Data centers rely heavily on consistent power and efficient electrical systems. By using IoT devices to monitor equipment in real time and implementing energy management systems, one data center improved both safety and efficiency. Early fault detection prevented major failures, and smarter energy use lowered costs—keeping critical systems online without interruption.

Healthcare

Hospitals and healthcare facilities need rock-solid electrical systems to keep life-saving equipment running. Adhering to strict electrical safety standards and using customized, compliant components ensures reliable power delivery. This commitment protects patients and staff while maintaining smooth, uninterrupted operations critical to patient care.

How HYCNC Supports Safe and Efficient Electrical Systems

At HYCNC, precision matters. Our CNC machining services deliver high-quality electrical components that meet the strictest safety and performance standards. This precision helps reduce the chances of component failure, which in turn supports safer and more efficient electrical systems.

We also customize parts to fit your specific needs and regulatory requirements. Whether you need components designed for NFPA 70E compliance or tailored to local electrical codes, we ensure each piece contributes to a reliable, code-compliant system.

Beyond quality parts, HYCNC works closely with you to improve overall system reliability and efficiency. Our collaborative approach means we understand your challenges and help you implement solutions that save energy, reduce downtime, and keep operations running smoothly in line with OSHA electrical regulations and industry best practices.