Key Factors Influencing Sheet Metal Cutting Costs

Understanding the factors that impact sheet metal cutting costs is essential for budgeting and project planning. Several key elements determine the final price of sheet metal fabrication and cutting services.

Material Type and Thickness

The type of metal used significantly affects cutting costs. Materials like aluminum are generally easier and less expensive to cut, while stainless steel and other hard metals require more time and specialized equipment, increasing costs. Thickness also matters—thicker sheets need more power and slower cutting speeds, which add to the overall expense.

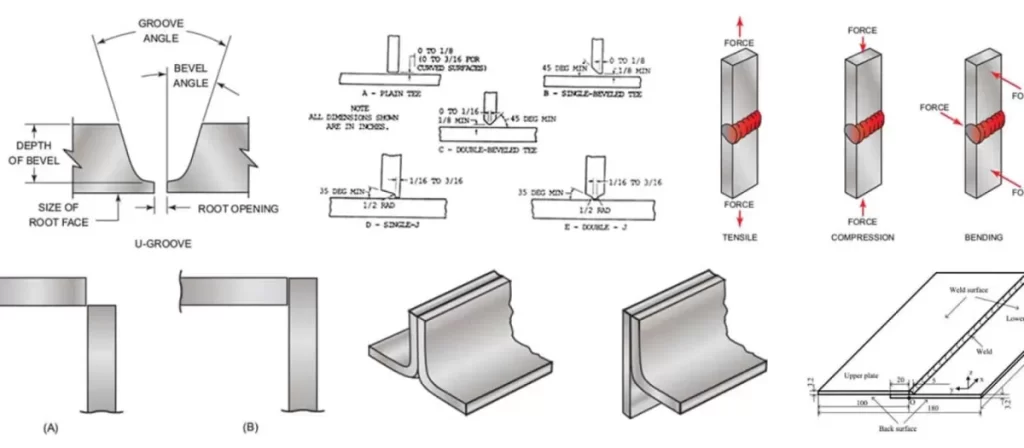

Cutting Process

Different cutting methods have varying price points. Laser cutting pricing tends to be higher but offers precision and smooth finishes. CNC sheet metal cutting provides accuracy and efficiency but can be costly depending on the complexity. Other methods like plasma or waterjet cutting might be more affordable or better suited for certain materials or thicknesses.

Design Complexity

Intricate designs with tight tolerances and detailed shapes require more time and precise machining. Complex cuts increase machine setup time and may need additional programming, which raises the sheet metal fabrication cost.

Labor and Machine Setup

The labor involved in setting up machines and programming cutting paths impacts the cost. Small or custom orders might require significant setup time, while repeat jobs benefit from faster turnaround, lowering the cost per piece.

Order Volume and Economies of Scale

Larger orders reduce the cost per unit through economies of scale. High volume production allows for quicker setup amortization and more efficient material use, resulting in significant bulk order sheet metal savings.

Finishing and Additional Processes

Additional steps like deburring, bending, welding, or coating add to the final metal cutting cost factors. Finishing ensures the part meets quality and functional standards but increases labor and processing time.

By understanding these factors, customers can better evaluate quotes and identify opportunities to optimize their sheet metal cutting projects for cost efficiency. For competitive pricing tailored to your project, contact experts like HYCNC who combine state-of-the-art CNC machining with industry knowledge.

Cost Saving Strategies for Sheet Metal Cutting

Keeping sheet metal cutting costs down is all about smart choices—from materials to methods. Here are some easy ways to save without sacrificing quality:

Optimize Material Selection

- Choose the right material for the job, not just the fanciest option. For example, aluminum is often cheaper and easier to work with than stainless steel but still strong enough for many applications.

- Avoid over-thick materials unless absolutely necessary since thickness drives up the metal cutting cost.

Simplify Design

- Complex shapes and tight tolerances add to labor and machine setup time.

- Use standard sizes and simple geometries to reduce waste and cutting time.

- Minimize holes, slots, and intricate contours where possible.

Leverage High Volume Production

- Bulk orders can lower the price per part.

- Economies of scale help offset setup costs and make your overall sheet metal fabrication cost more affordable.

Choose Cost Effective Cutting Methods

- Laser cutting is great for precision but can be pricey on thicker metals.

- Waterjet or plasma cutting sometimes offer better value depending on your sheet metal design optimization needs.

- CNC sheet metal cutting providers like HYCNC can recommend the best process based on your goals.

Work with Expert Providers like HYCNC

- Experienced CNC services can advise on materials, design tweaks, and the best cutting methods.

- They help avoid costly mistakes and ensure you get accurate laser cutting pricing or other metal cutting cost factors upfront.

- Partnering with pros saves time, money, and headaches while delivering high-quality results.

By making thoughtful decisions and collaborating with skilled providers such as HYCNC, you can significantly reduce your sheet metal cutting cost without cutting corners on quality.

Estimating Sheet Metal Cutting Costs

Estimating sheet metal cutting costs can be straightforward if you understand the main methods. Here’s how you can get a clear picture:

Manual Estimation Methods

You can calculate costs by breaking down each factor: material type and thickness, cutting process, labor, and setup time. For example, multiply the material cost per pound by the weight, add machine hours multiplied by the hourly rate, and include labor costs. It’s a simple approach but can get tricky with complex designs or multiple steps.

Using Software Tools

Many CNC and sheet metal fabrication shops use specialized software to estimate costs faster and more accurately. These tools factor in material usage, cutting time, tool wear, and even waste. They’re great for comparing different materials or cutting processes like laser versus plasma, helping you find cost-effective options quickly.

Getting Accurate Quotes

The best way to know your exact costs is to request detailed quotes from experienced fabricators like HYCNC. Provide your design files and specs, and they’ll break down your sheet metal cutting cost including all factors. This saves guesswork and ensures no hidden fees pop up later.

Using a mix of these methods helps you plan your budget better and choose the right partner for your sheet metal fabrication needs.

Why Choose HYCNC for Sheet Metal Cutting

When it comes to sheet metal cutting cost and quality, HYCNC stands out as a reliable partner. We combine advanced CNC machining technology with years of experience to deliver precise, cost-effective solutions tailored to your needs. Whether you’re working with aluminum, stainless steel, or other metals, our expert team ensures accurate cuts with minimal waste, helping you save money and time.

Here’s why HYCNC is a smart choice for your sheet metal fabrication:

- Competitive Pricing: We focus on efficiency and optimized processes to offer laser cutting pricing and CNC sheet metal cutting services that fit your budget.

- High Quality: Our skilled operators and modern machines guarantee consistent, clean cuts that reduce rework and improve your product’s finish.

- Flexible Volume Options: From prototyping to bulk orders, we can handle your job size with quick turnaround times, helping you benefit from economies of scale.

- Design Support: We assist with sheet metal design optimization to reduce costs without compromising functionality.

- Local Service: Based in the U.S., we understand the needs of American customers and provide prompt, clear communication every step of the way.

By choosing HYCNC, you get more than just sheet metal cutting—you get a partner committed to delivering cost effective metal fabrication solutions that help your business grow.

FAQs about Sheet Metal Cutting Cost

What factors impact sheet metal cutting cost the most?

Material type and thickness, cutting process, design complexity, labor and setup time, order volume, and any finishing work all play a big role in your final cost.

How can I lower my sheet metal cutting cost?

Opt for common materials, simplify your design, order in bulk, and choose the right cutting method for your needs. Working with experienced providers like HYCNC can also save you money.

Is laser cutting pricing more expensive than other methods?

Laser cutting can be pricier upfront but offers high precision and speed, sometimes saving money on finishing and labor. The best choice depends on your project’s needs.

Do order volumes affect pricing?

Yes. Larger orders often come with discounts thanks to economies of scale, reducing the sheet metal fabrication cost per unit.

Can I estimate sheet metal cutting cost on my own?

Basic estimates are possible with manual calculations or software tools, but for accuracy, getting a detailed quote from a trusted provider is best.

What materials are more cost-effective for sheet metal cutting?

Aluminum tends to be more cost-effective compared to stainless steel, but your choice should balance durability and price for your application.

Why choose HYCNC for sheet metal cutting?

HYCNC offers expert CNC sheet metal cutting services with competitive pricing, fast turnaround, and the ability to handle different materials and complex designs efficiently.