Are you struggling to keep your supply chain lean and responsive? Streamlining your operations with on-demand manufacturing can transform your business, slashing costs and boosting efficiency. As a manufacturing professional, I understand the pressure to deliver high-quality products fast while navigating disruptions and rising costs. With years of industry experience, I’m here to share proven strategies that go beyond theory—practical solutions to make your supply chain agile and future-ready. In this guide, you’ll discover how on-demand manufacturing, like CNC machining and 3D printing, cuts waste, shortens lead times, and adapts to demand shifts. From actionable steps to real-world examples, including how HYCNC’s precision services empower businesses, this post will equip you to optimize your operations. Ready to revolutionize your supply chain? Let’s get started!

What is On-Demand Manufacturing

On-demand manufacturing is a production model that creates goods only when there is a confirmed order, rather than producing large quantities in advance. This approach minimizes inventory waste and reduces the risks of overproduction. It relies heavily on key technologies like CNC machining, 3D printing (also known as additive manufacturing), and advanced software systems, enabling businesses to produce parts and products quickly and flexibly.

The benefits of on-demand manufacturing include faster turnaround times, cost savings by eliminating excess inventory, and the ability to customize products easily. For example, a small electronics company might use CNC machining services to produce custom components only when a customer places an order, avoiding stockpiling outdated parts. Similarly, 3D printing allows rapid prototyping and small-batch production that adapts to changing market demands.

By embracing on-demand production, companies can respond more effectively to customer needs and market shifts, making their supply chains more agile and efficient.

Why Supply Chains Need Streamlining

Supply chains today face a lot of pressure. Common pain points include long lead times, excess inventory, and unpredictable demand. These issues cause delays, higher costs, and wasted resources. When supply chains aren’t efficient, businesses struggle to meet customer expectations and stay competitive.

The impact of these inefficiencies is clear: slower delivery, unhappy customers, and increased operating expenses. Traditional supply chains often lack flexibility, making it tough to adapt to sudden market changes or disruptions.

That’s why there’s a growing need for agile systems. Streamlining the supply chain means cutting out waste, improving communication, and reacting quickly to changes in demand. An agile supply chain can handle fluctuations without breaking down, which is essential for businesses looking to stay lean and responsive in the fast-paced US market.

How On-Demand Manufacturing Optimizes Supply Chains

On-demand manufacturing is a game-changer when it comes to streamlining supply chains. One of its biggest perks is just-in-time production. Instead of holding large inventories, products are made exactly when needed. This cuts down waste and frees up warehouse space, improving overall supply chain efficiency.

Flexibility and scalability play a big role here too. On-demand production can quickly adjust to changes in demand, whether you need a small batch or a large run. This agility helps businesses avoid overproduction and stay responsive to market shifts.

Reduced lead times are another benefit. Since items are produced closer to the order time, delivery speeds up significantly. Faster turnaround means you can meet customer needs quicker, boosting satisfaction and cutting delays.

Cost efficiency also improves as manufacturers lower inventory costs and reduce storage expenses. By producing only what’s necessary, companies save money and operate leaner.

For example, a U.S.-based electronics supplier switched to on-demand manufacturing with CNC machining services and 3D printing. They cut lead times by 40% and reduced inventory costs by 35%, all while adapting faster to customer demand.

In short, on-demand manufacturing makes supply chains smarter, faster, and more cost-effective, which is exactly what businesses need to stay competitive today.

Key Technologies Driving On-Demand Manufacturing

On-demand manufacturing relies on several key technologies to deliver fast, flexible, and precise production. Here’s a quick look at the main players shaping this shift:

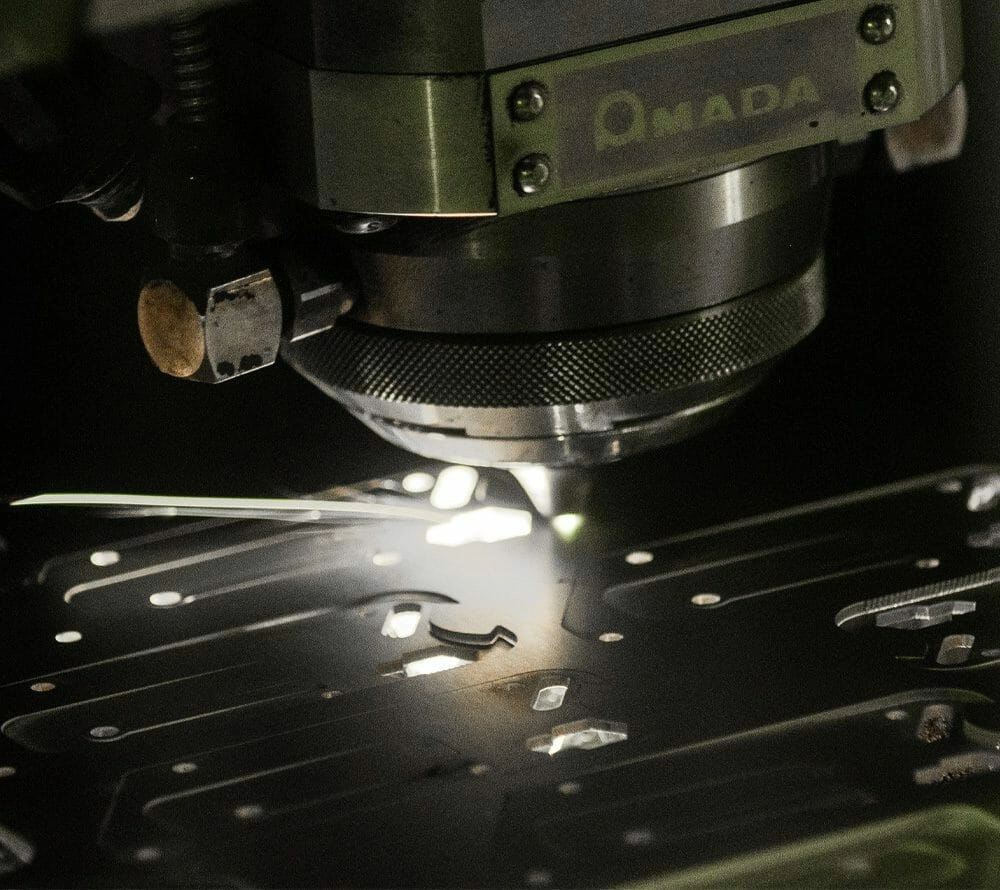

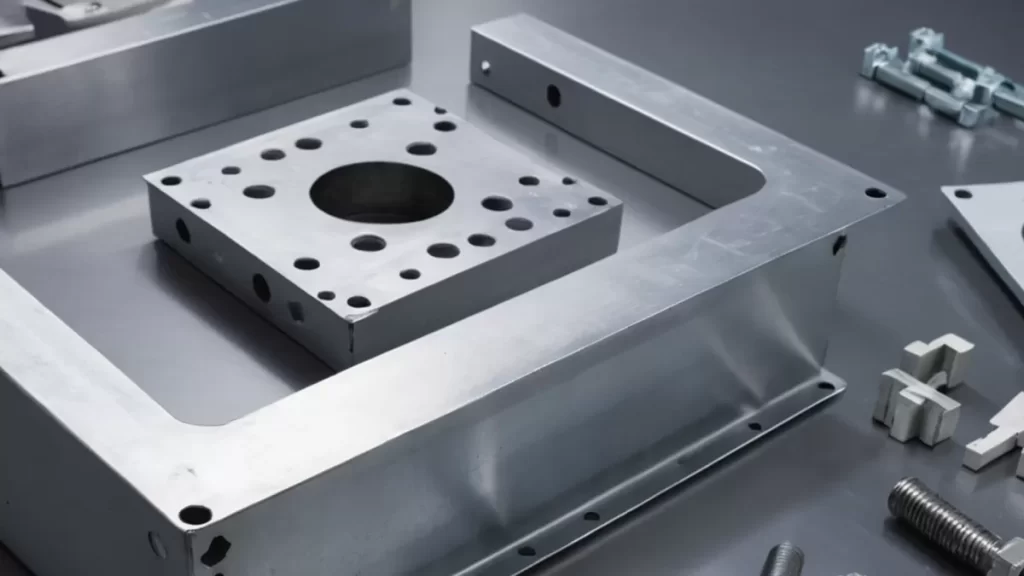

CNC Machining

Computer Numerical Control (CNC) machining offers precision and repeatability, making it ideal for custom parts and low-volume runs. CNC machining services allow quick adjustments without retooling the entire line, which helps keep supply chains responsive and reduces waste.

3D Printing

Also known as additive manufacturing, 3D printing builds parts layer by layer, enabling rapid prototyping and small-batch production. This technology speeds up development cycles and cuts lead times, perfect for businesses looking to scale on demand or customize products locally.

AI and IoT

Artificial intelligence combined with the Internet of Things (IoT) improves demand forecasting, production scheduling, and real-time monitoring. These technologies provide smarter data insights that optimize inventory management and streamline operations.

Blockchain

Blockchain offers secure, transparent supply chain tracking. It helps verify product authenticity and enhances trust between manufacturers and suppliers by providing an immutable record of transactions and material origins.

ERP Integration

Enterprise Resource Planning (ERP) systems tie everything together. Integrating on-demand manufacturing with ERP allows seamless communication across supply chain functions—keeping order management, inventory, and production aligned for better efficiency.

By leveraging these technologies, on-demand manufacturing reshapes traditional supply chains into agile, cost-efficient networks ready for today’s fast-paced market.

Steps to Implement On-Demand Manufacturing in Your Supply Chain

To get started with streamlining your supply chain using on-demand manufacturing, follow these practical steps:

1. Conduct a Supply Chain Audit

Begin by reviewing your current operations. Identify bottlenecks, excess inventory, or delays. Understanding where inefficiencies exist helps you focus on areas where on-demand production can have the biggest impact.

2. Partner with Reliable On-Demand Manufacturers

Find manufacturers experienced in CNC machining services, 3D printing, and just-in-time manufacturing. Look for those with a proven track record in supply chain optimization and the ability to scale quickly based on your demand forecasting.

3. Invest in Automation and Real-Time Tracking

Implement supply chain automation tools and IoT tracking systems. These technologies provide real-time visibility into inventory levels, production status, and shipment timelines, helping reduce lead times and improve inventory management.

4. Establish Clear KPIs

Set measurable goals like lead time reduction, order accuracy, cost savings, and inventory turns. Tracking these KPIs ensures your on-demand manufacturing efforts are delivering real supply chain efficiency.

5. Foster Supplier Collaboration

Work closely with your suppliers to align production schedules and share data. This collaboration supports flexible and responsive manufacturing, vital for handling fluctuating demand without overstocking or delays.

Take Action

Start small with pilot projects to test the benefits of on-demand manufacturing for your business. Use the insights to scale gradually, improving supply chain agility and cutting costs across the board.

Challenges and Solutions in Adopting On-Demand Manufacturing

Switching to on-demand manufacturing isn’t without its hurdles. Many businesses face common challenges as they try to streamline their supply chain with on-demand production.

Common Challenges

- Integration issues: Connecting new on-demand systems with existing supply chain software can be tricky.

- Quality control: Keeping consistent quality when producing in smaller batches or using new tech like 3D printing can be tough.

- Cost concerns: Initial investments in CNC machining services, automation, or AI-powered tools might seem high.

- Supplier coordination: Getting all partners on board with just-in-time manufacturing requires strong collaboration.

- Demand forecasting: On-demand manufacturing depends heavily on accurate forecasts, which can be tricky in volatile markets.

Solutions and Examples

- Use ERP integration: Bringing on-demand manufacturing into your existing Enterprise Resource Planning system helps smooth data flow and improves inventory management.

- Partner with trusted manufacturers: Choose experienced on-demand production providers who specialize in CNC and additive manufacturing to ensure quality.

- Start small with pilot projects: Test on-demand processes on select product lines before a full rollout to minimize risk.

- Invest in automation and real-time tracking: Tools powered by AI and IoT help track orders and predict issues early, keeping supply chains agile.

- Improve supplier relationships: Share real-time data and forecasts to ensure everyone is aligned on production schedules.

For example, a U.S. electronics company working with an on-demand CNC machining service improved lead times by 30% by integrating real-time tracking and collaborating closely with suppliers. This approach helped them reduce inventory costs and respond faster to market demand.

By anticipating these challenges and applying practical solutions, businesses can make the switch to on-demand manufacturing smoother, boosting supply chain efficiency without losing control.

The Future of Supply Chains with On-Demand Manufacturing

Looking ahead, on-demand manufacturing is set to reshape how supply chains function across the U.S. Emerging trends like greater integration of AI-driven demand forecasting, advanced additive manufacturing, and real-time supply chain automation will make processes faster and smarter. This means companies can better predict needs, reduce waste, and respond quickly to market shifts—all critical for staying competitive.

Sustainability is another big win here. On-demand production cuts down excess inventory, lowers material waste, and reduces transportation emissions by producing closer to the customer. This aligns perfectly with the growing push for greener, more responsible supply chains.

HYCNC is playing a key role in this future. As a trusted CNC machining services provider, they deliver precise, scalable production that fits perfectly with on-demand needs. Their expertise helps businesses across the U.S. streamline operations, cut lead times, and boost supply chain efficiency through flexible, reliable CNC service.

By embracing on-demand manufacturing and partnering with forward-thinking providers like HYCNC, companies can build supply chains that are agile, cost-effective, and ready for what’s next.