Are you curious about zinc plating colors and how they can transform your CNC parts? Choosing the right zinc plating finish isn’t just about looks—it’s about boosting durability, ensuring corrosion resistance, and making your components stand out.

As a CNC machining expert, I’ve seen firsthand how the right colored zinc plating can elevate projects across industries like automotive, aerospace, and construction. With HYCNC’s advanced plating solutions, you can achieve vibrant, long-lasting finishes tailored to your needs.

In this guide, you’ll discover the most popular zinc plating colors, their unique benefits, and how to pick the perfect one for your next project. Ready to dive into the world of zinc electroplating colors? Let’s get started!

What is Zinc Plating Why Zinc Plating Colors Matter HYCNC’s Expertise in Zinc Plating

Zinc plating is a popular metal finishing process where a thin layer of zinc is electroplated onto steel or other metals. This protective coating helps prevent rust and corrosion, extending the life of your parts and improving their performance. But zinc plating offers more than just durability—it also comes in a variety of colors that can enhance the look and functionality of your components.

Zinc plating colors matter because they are not only about aesthetics. Different colors come from specific chromate conversion coatings that provide varying levels of corrosion resistance and chemical protection. For example, yellow zinc plating offers strong corrosion resistance and is commonly used in automotive parts, while clear zinc plating gives a clean look with moderate protection. These colors serve as quick visual cues for quality and type of protection on your parts.

At HYCNC, we bring extensive expertise in zinc plating and surface finish services, specializing in precision CNC machining combined with high-quality, colorful zinc electroplating. Our advanced processes ensure consistent, corrosion-resistant coatings in a range of zinc plating colors that meet your exact project needs. We understand how important reliable finishes are to your CNC applications and deliver metal finishing colors that perform and impress every time.

How Zinc Plating Colors Are Achieved

Zinc plating colors come from a process called chromate conversion coating or passivation, which adds a thin protective layer on top of the zinc. This layer controls the color and boosts corrosion resistance. The base zinc layer is usually silver or gray, but the chromate treatment gives it the final color like yellow, black, green, or clear. Adjusting the chemicals and process time changes the color and finish.

Common Zinc Plating Colors and Their Properties

- Clear Zinc Plating: Offers a shiny, silver look with good corrosion resistance. It’s a popular choice when you want the natural zinc finish.

- Yellow Zinc Plating: Known as yellow chromate, it adds a gold tint. It improves corrosion resistance, often used in automotive and industrial parts.

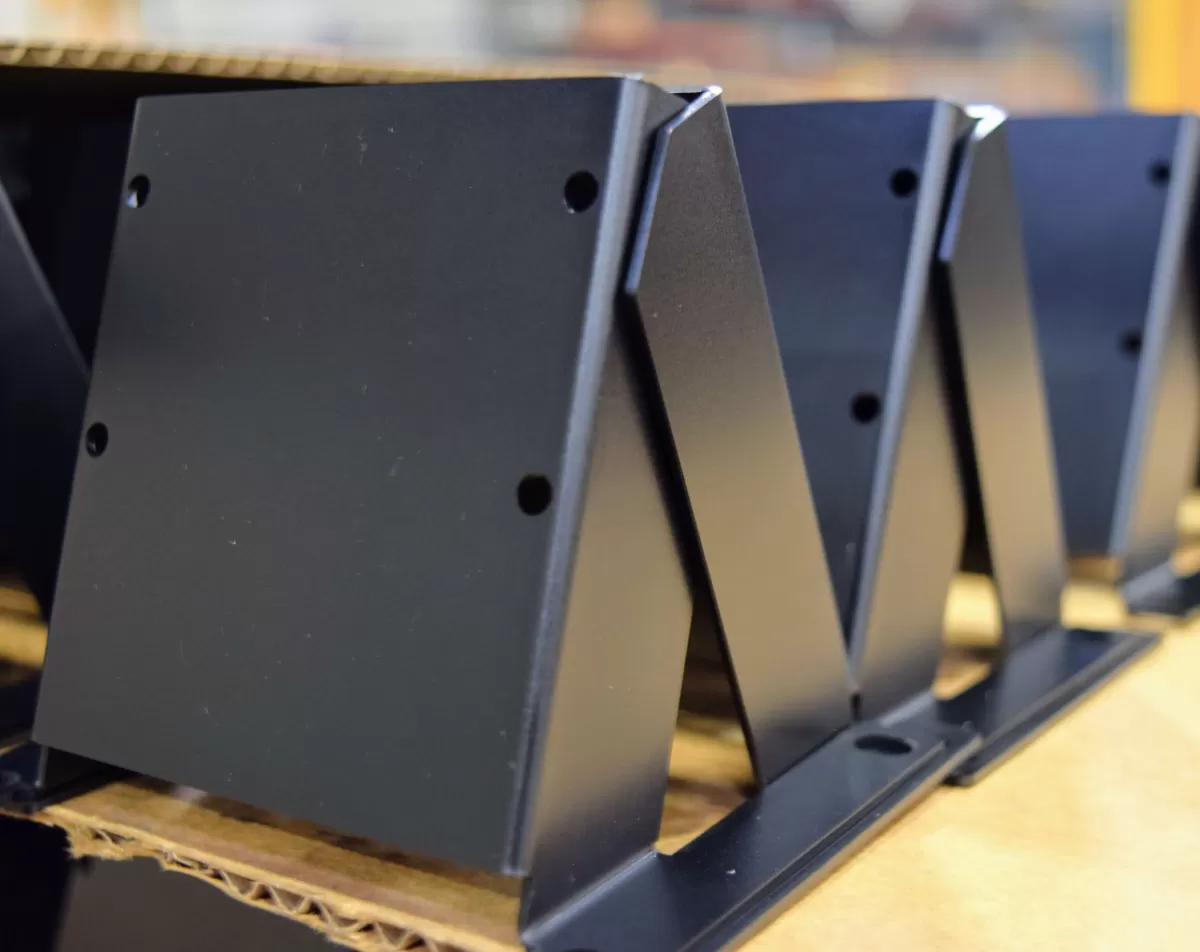

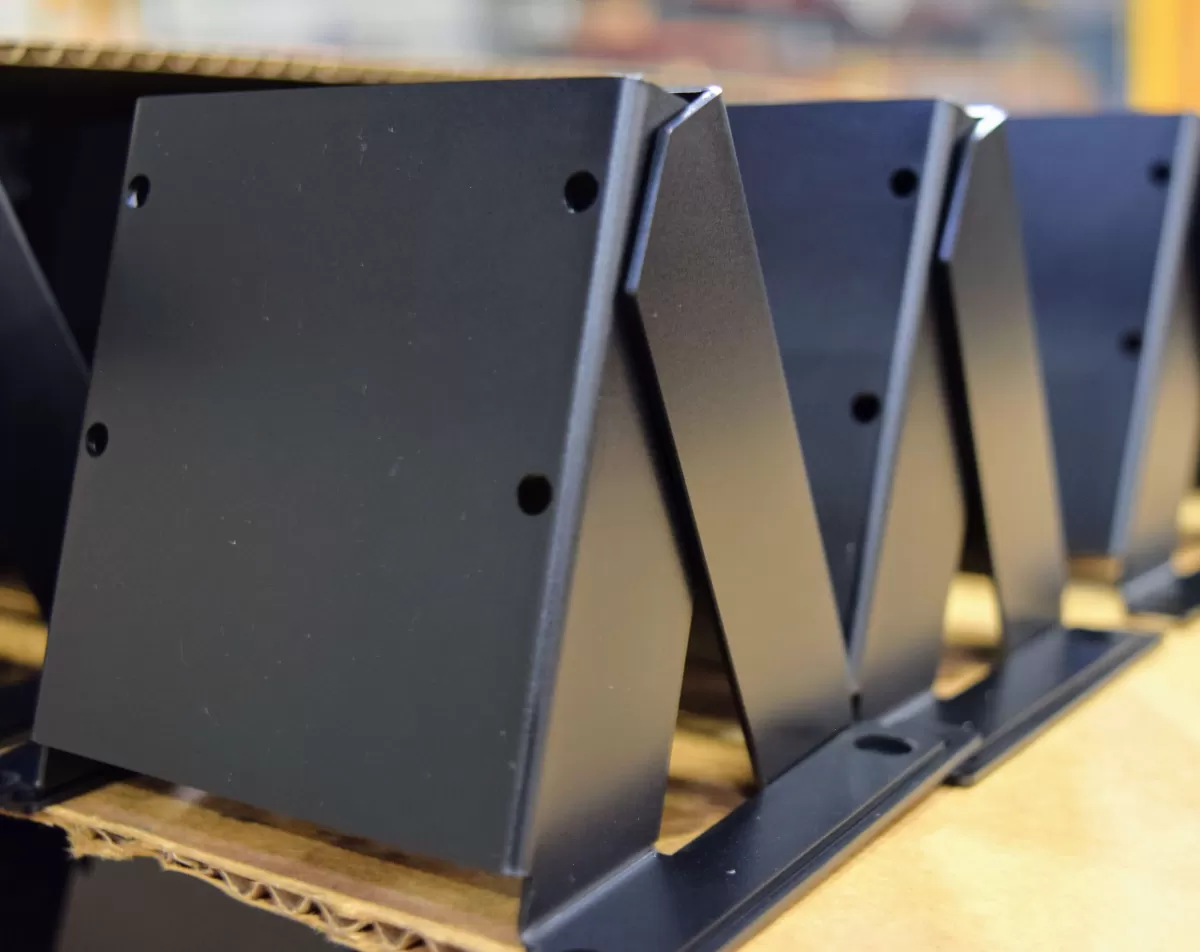

- Black Zinc Plating: Provides a matte or semi-gloss black finish. Besides visual appeal, it offers enhanced protection against rust.

- Green Zinc Plating: Less common but adds a greenish tint with great corrosion resistance, mainly for specialized applications.

Each color not only changes the look but also slightly affects performance, particularly in corrosion resistance and durability.

Factors Influencing Color Consistency

Consistent zinc electroplating colors depend on several things:

- Chemical Bath Composition: Variations in the plating bath’s chemical mix can alter color tones.

- Bath Temperature: Even small temperature changes affect how the color forms.

- Process Timing: How long parts stay in the plating and chromate baths changes the thickness and color of the coating.

- Metal Surface Preparation: Clean, properly prepped surfaces make colors more uniform and lasting.

- Post-Treatment Processes: Drying and sealing steps help lock in the color and protect it from fading.

Maintaining tight control over these factors is key to delivering reliable and consistent metal finishing colors for your CNC machined parts.

For more on zinc and its applications, you can check out our insights on zinc die casting.

Benefits of Colored Zinc Plating

Colored zinc plating offers more than just good looks. Here’s why it’s a smart choice for many projects:

- Enhanced Corrosion Resistance: Colors like yellow, black, and green often come from chromate conversion coatings that boost protection against rust and wear. This makes your parts last longer, especially in harsh environments.

- Improved Identification: Different zinc electroplating colors help quickly identify parts or tools by function, size, or batch, saving time on the shop floor.

- Better Surface Durability: Colored finishes add an extra layer that can resist scratches and minor damage, keeping parts looking good and functioning well.

- Custom Appearance: Whether you want a professional clear zinc plating look or a striking black or green finish, colored zinc plating can match your brand or project needs.

- Easy Inspection: Some color finishes make it easier to spot defects or wear early, which is critical for maintenance and quality control.

These benefits make colored zinc plating a practical and cost-effective choice in CNC machining and other metal finishing applications. For more on surface finishes, you can also check out our insights on zinc plating vs nickel plating.

Applications of Zinc Plating Colors in CNC Machining

Zinc plating colors play a big role in CNC machining by adding both function and style to metal parts. Here’s how these colored zinc finishes are used in the industry:

- Corrosion Protection: Different zinc plating colors, like yellow zinc plating or black zinc plating, offer varying levels of rust resistance. This helps parts last longer, especially in harsh environments.

- Visual Identification: Using distinct metal finishing colors makes it easy to identify parts quickly. For example, clear zinc plating might be used for standard parts, while green zinc plating signals special corrosion-resistant coatings.

- Surface Finish Enhancement: Colored zinc plating improves the overall look and feel of CNC-machined components, making them more appealing and meeting specific project aesthetics.

- Performance Performance: Some colors correspond to different passivation or chromate conversion coating levels, influencing performance under different conditions.

- Industry-Specific Uses: Sectors like automotive, aerospace, and industrial manufacturing often rely on zinc plating colors for functional and regulatory reasons.

In short, zinc plating colors add value to CNC machining by boosting protection, helping with organization, and improving appearance for customers across the United States.

Choosing the Right Zinc Plating Color for Your Project

Picking the right zinc plating color depends on what you need for your CNC machined parts. Here’s what to keep in mind:

-

Purpose: Are you after corrosion resistance, aesthetics, or both? For example, yellow zinc plating offers great corrosion protection with a warm, gold-like finish, while black zinc plating provides a sleek, modern look plus good durability.

-

Environment: Consider where the part will be used. Clear zinc plating works well indoors or in less harsh settings, but green zinc plating might be better for tougher outdoor conditions because of its added corrosion-resistant coatings.

-

Compatibility: Some zinc electroplating colors work better with certain metals or finishes. Check if the color matches the base material and any passivation or chromate conversion coating applied to maintain color consistency.

-

Project Requirements: Think about weight, cost, and delivery time. Some finishes can be quicker or less expensive, which might fit your timeline and budget better.

At HYCNC, we guide you through these choices to get the perfect metal finishing colors that meet your CNC machining needs while ensuring durability and style.

The HYCNC Advantage in Zinc Plating

At HYCNC, we bring years of experience in CNC machining combined with top-tier zinc plating services to deliver superior surface finishes. We understand that zinc plating colors are not just about looks—they provide essential corrosion-resistant coatings that extend the life of your parts.

Here’s why HYCNC stands out in zinc plating colors:

- Precision and Consistency: Our advanced plating process ensures uniform zinc electroplating colors every time, whether it’s yellow zinc plating, black zinc plating, or clear zinc plating.

- Custom Solutions: We tailor the chromate conversion coating and passivation steps according to your project’s needs, guaranteeing the right color and protection level.

- Quality Control: Rigorous testing keeps your parts free from defects, ensuring durability in CNC machining applications exposed to tough environments.

- Fast Turnaround: We know time is money. Our efficient workflows handle your orders quickly without sacrificing quality.

- Local Support: Based in the U.S., HYCNC offers personalized service made for American manufacturers and CNC shops, with easy communication and quick problem solving.

Choosing HYCNC means getting reliable zinc plating colors that improve both the function and appearance of your metal parts. Whether you need green zinc plating for added corrosion resistance or standard metal finishing colors, we’ve got your project covered.

Maintenance and Care for Zinc-Plated Parts

Taking care of zinc-plated parts helps keep their colors vibrant and extends their corrosion-resistant properties. Here’s how to maintain your zinc plating colors effectively:

- Keep Parts Clean: Regularly wipe down zinc-plated surfaces with a soft cloth to remove dirt, dust, and grime. Avoid harsh chemicals that can break down the chromate conversion coating.

- Avoid Moisture Exposure: Zinc plating does a great job resisting rust, but prolonged exposure to moisture, especially salty or acidic environments, can affect the finish. Store parts in dry places when possible.

- Use Mild Cleaners: Clean with mild soap and water if needed. Stay away from abrasive cleaners or steel wool that can scratch the zinc plating and damage the passivation layer.

- Inspect Regularly: Check for any signs of wear or damage to the finish. Early detection helps prevent corrosion and color fading.

- Reapply Protective Coatings: For parts exposed to harsh conditions, consider reapplying corrosion-resistant coatings or passivation treatments to maintain the original zinc electroplating colors.

- Handle with Care: Avoid rough handling to prevent chipping or scratches that can lead to rust spots.

By following these steps, your zinc-plated CNC machined parts will last longer and keep their metal finishing colors looking sharp.

FAQs

What is zinc plating?

Zinc plating is a metal finishing process where a thin layer of zinc is coated onto a metal surface to protect it from corrosion and improve its appearance.

Why do zinc plating colors matter?

Colors tell you about the type of chromate conversion coating used, which affects corrosion resistance and the final look. Different colors also help match specific design or functional needs.

How are zinc plating colors achieved?

Colors come from different chromate conversion coatings applied over the zinc layer. Common colors include clear, yellow, black, and green.

Which zinc plating color offers the best corrosion resistance?

Yellow zinc plating usually provides strong corrosion resistance due to its thick chromate layer, but black zinc plating also offers good protection while giving a sleek look.

Can zinc plating be used for CNC machined parts?

Absolutely. Zinc plating colors are common in CNC machining to protect parts and achieve the desired surface finish and color.

How do I choose the right zinc plating color for my project?

Consider the environment (indoor vs. outdoor), corrosion resistance needed, and appearance. We can help you select the right color based on these factors.

Does zinc plating require maintenance?

Yes. To keep parts looking great and resist corrosion, clean them regularly and avoid harsh chemicals.

What makes HYCNC’s zinc plating service unique?

We offer expert recommendations, consistent color quality, and reliable corrosion-resistant coatings tailored to local U.S. manufacturing needs.

For more details on metal finishing options, check out our post on Zinc Plating vs Nickel Plating.

Call to Action

Ready to improve your parts with high-quality zinc plating colors? At HYCNC, we deliver corrosion-resistant coatings that not only protect but also enhance the look of your CNC machined components. Whether you need yellow zinc plating, black zinc plating, or clear zinc plating, we’ve got the expertise to get it right every time.

Contact us today to discuss your project and find the perfect zinc plating color for your needs. Let’s give your parts the durable, precise finish they deserve. Reach out now to get started with HYCNC’s trusted zinc plating services.