Struggling to find a reliable sheet metal tapping service for your next project? Choosing the right CNC tapping service can transform your designs into precision-engineered parts that fit perfectly every time.

As a leader in CNC machining, HYCNC’s online sheet metal tapping service delivers unmatched accuracy, speed, and versatility. With over 14 years of expertise, we’ve streamlined the process to make your projects effortless and cost-effective.

In this guide, you’ll discover the advanced capabilities of our online sheet metal tapping service, from precision threading to material options and fast turnarounds. Ready to bring your ideas to life? Let’s get started!

What is Sheet Metal Tapping

Definition of Sheet Metal Tapping

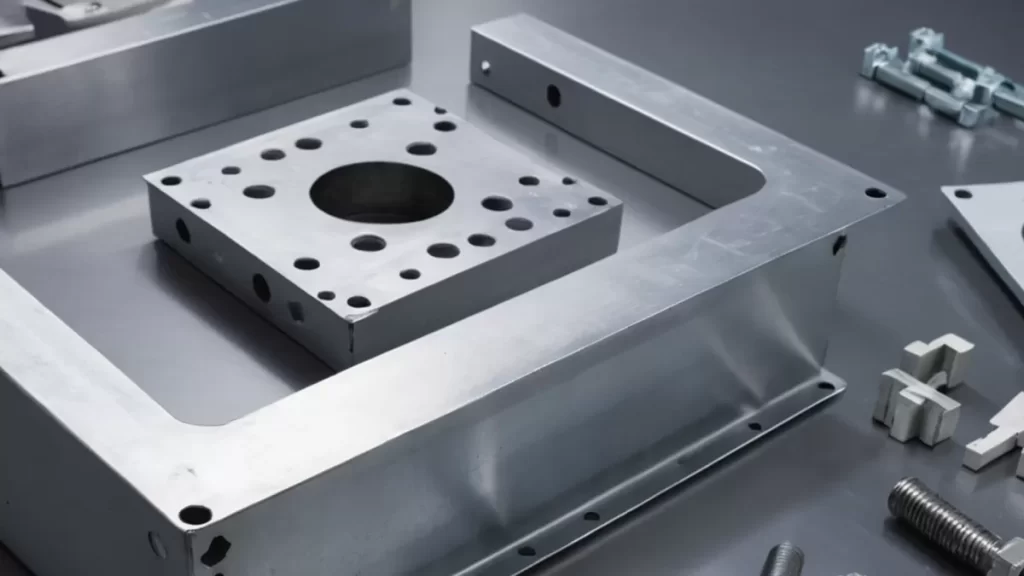

Sheet metal tapping is the process of creating internal threaded holes in metal sheets so screws or bolts can be securely fastened. This involves cutting threads inside a pre-drilled hole, allowing screws or fasteners to grip tightly without needing a separate nut. It’s a critical step in producing strong, reliable assemblies in sheet metal fabrication.

Why Tapping Matters in Industry

Tapping sheet metal plays a key role in manufacturing across multiple industries:

- Automotive: Threaded holes are essential for engine parts, chassis components, and body panels.

- Aerospace: Precision tapping enables lightweight, durable assemblies with secure fastenings critical for safety and performance.

- Electronics: Enclosures, brackets, and mounting solutions rely on clean, reliable tapped holes for assembly and maintenance.

Why Choose HYCNC for Tapping Needs

At HYCNC, our online CNC tapping services stand out thanks to:

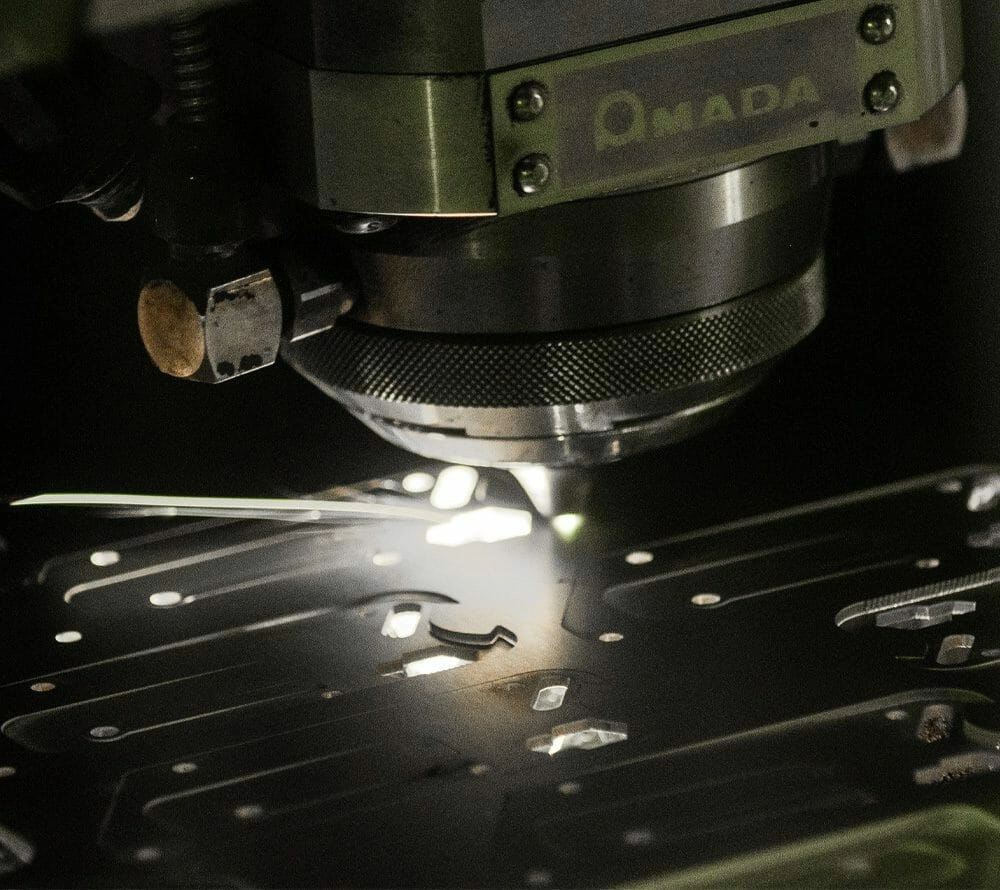

- Precision threading using advanced CNC equipment for consistent, high-quality thread finishes.

- Support for various thread sizes—metric, imperial, and custom—to meet unique design requirements.

- Expertise in handling multiple materials including aluminum, stainless steel, brass, and more.

Choosing HYCNC means trusting a partner with over 14 years of experience ensuring your sheet metal tapping needs are met with reliability and precision.

Key Capabilities of HYCNC’s Online Sheet Metal Tapping Service

Precision Threading with CNC Technology

At HYCNC, we deliver high accuracy tapping using CNC-controlled machines. This means every threaded hole meets your exact specifications, whether you need metric, imperial, or custom thread sizes. Our process ensures strong, consistent threads for reliable assembly.

Material Versatility for Various Applications

Our sheet metal tapping service works with a wide range of materials including aluminum, stainless steel, brass, copper, and select plastics. We accommodate thicknesses from 0.5mm up to 6mm, depending on the material, giving you flexibility for different projects.

Fast Turnaround Times to Keep Projects Moving

Standard production usually takes 4 to 6 days, but we also offer expedited options when you need parts quicker. If you combine tapping with other services like bending or laser cutting, expect an additional 1 to 2 days. This helps keep your entire sheet metal fabrication process streamlined.

Convenient Online Configurator for Instant Quotes

Our easy-to-use online tool lets you upload CAD files (DXF, STEP, STP) and get instant pricing. You’ll see a 3D preview of your part and get real-time design feedback to make sure your tapping plan is perfect and manufacturable before ordering.

Strict Quality Assurance for Reliable Results

We maintain tight quality control handled by skilled technicians using advanced inspection tools. Our process follows industry standards, including ISO 2768-1 tolerances, so you get consistent, high-quality tapped holes every time.

Complementary CNC Sheet Metal Services

HYCNC offers full integration with other fabrication options like laser cutting, CNC bending, and finishing services such as powder coating and anodizing. Need hardware insertion? We provide options like PEM press-fit nuts and studs to complete your assembly quickly.

This combination of precision, material flexibility, speed, and quality control makes HYCNC’s online sheet metal tapping service a go-to solution for CNC machining and custom metal parts in the US manufacturing market.

Benefits of Choosing HYCNC Online Sheet Metal Tapping Service

Choosing HYCNC for your sheet metal tapping needs comes with several important benefits that make your projects easier and more reliable.

Efficient Online CNC Tapping Service

Our streamlined online ordering system speeds up the process and cuts down lead times. You can upload designs and get instant quotes quickly, which means less waiting and faster production.

Cost Effective CNC Machining

We offer competitive pricing with no minimum order requirements, making our service affordable whether you need a single prototype or a large production run. This helps you manage your budget without sacrificing quality.

Scalable Precision Threading Solutions

No matter the size of your order—from one-off prototypes to thousands of custom metal parts—our CNC sheet metal tapping service scales to fit your needs. This flexibility supports your project growth without hassle.

Customization for Exact Needs

We tailor thread sizes and hole placements exactly to your specifications. This level of customization ensures your threaded hole machining fits perfectly with your assembly or design requirements.

Reliable CNC Service Backed by Experience

HYCNC’s 14+ years of CNC machining expertise combined with advanced CNC controlled equipment means you get consistent, high-quality results you can depend on every time.

By choosing HYCNC, you’re getting a trusted partner for your sheet metal fabrication and tapping that balances speed, precision, and cost for the best results in the U.S. market.

How HYCNC Online Sheet Metal Tapping Service Works

Our online sheet metal tapping service is designed to be simple and fast, so you get precision-threaded parts without hassle. Here’s how it works step-by-step:

Step 1 Upload Your CAD File

Start by uploading your CAD design in formats like DXF, STEP, or STP. Our platform supports these files to understand your exact part geometry for precision threading.

Step 2 Select Tapping Specifications

Choose your thread size, material (aluminum, stainless steel, brass, etc.), and quantity. We support both metric and imperial threads and handle various sheet metal tapping needs.

Step 3 Review Instant Quote and 3D Preview

You get an instant quote along with a 3D preview of your part. This real-time feedback helps you validate the design and make sure all threaded holes are perfect for manufacturability.

Step 4 Approve and Place Your Order

Once you’re satisfied, approve your design and place the order. We start rapid production using our CNC tapping services with high accuracy and fast turnaround.

Step 5 Receive Your High-Quality Tapped Parts

Get your precision tapped parts delivered with optional finishing services like powder coating or hardware insertion if needed. Everything is backed by strict quality checks to meet industry standards.

This simple process makes HYCNC a dependable choice for anyone looking for custom metal parts with expertly machined threaded holes.

Design Tips for Optimal Sheet Metal Tapping Results

Getting the best out of our sheet metal tapping service means following some simple design rules. These help avoid common problems like stripped threads or distorted parts and make sure your tapped holes hold strong. Here are the key points to keep in mind when preparing your design for CNC tapping services:

-

Use Proper Hole Sizing

Make sure the hole size matches the thread specifications exactly. Too tight can cause binding, too loose may result in weak threads or stripped holes.

-

Keep Distance from Bend Lines

Maintain a safe gap between tapped holes and any bend lines. This prevents distortion or cracking during the bending process, keeping threads intact.

-

Consider Thread Engagement

The depth of the tapped thread must be enough for the screw or bolt to grip firmly. Stick to recommended diameter-to-depth ratios for each material to ensure strength.

-

Follow HYCNC Tapping Guidelines

We provide detailed guidelines that cover material-specific tips, thread types, and hole placement best practices. Referencing these helps avoid manufacturing issues upfront.

By designing with these points in mind, you’ll get precise, durable threaded holes that perform well in your application. It also speeds up production and reduces rework for your project.

Our online CNC machining platform supports real-time feedback during file upload, so you can double-check these factors before ordering. This way, your custom metal parts come out just right every time.

Industries and Applications for Sheet Metal Tapping

Our sheet metal tapping service is designed to meet the needs of several key industries where precision and reliability matter most.

Automotive

We provide threaded holes for critical engine parts, chassis components, and body panels. Our tapping ensures strong, durable connections that hold up under tough conditions.

Aerospace

In aerospace, every part has to be lightweight and long-lasting. Our precision threading creates secure fastenings for assemblies where safety and performance are top priorities.

Electronics

From enclosures to mounting brackets, durable threaded holes keep your electronic devices firmly together. We help create parts that protect sensitive components with exact thread sizes.

Industrial Equipment

Heavy-duty machinery and fixtures need strong, reliable tapped holes to handle stress and wear. Our CNC sheet metal tapping delivers tough, high-quality threads that maintain integrity through long use.

Across these sectors, our CNC tapping services provide the accuracy and consistency needed for secure, efficient assembly in sheet metal fabrication projects. Whatever your application, our expertise supports the manufacture of custom metal parts with the right threads every time.

Why HYCNC Stands Out in CNC Sheet Metal Tapping

When it comes to sheet metal tapping and CNC machining services, HYCNC sets itself apart with a combination of experience, reach, and customer focus tailored for the U.S. market.

Extensive CNC Machining Expertise

With over 14 years in the industry, we bring deep knowledge in precision threading and sheet metal fabrication. This experience means your threaded hole machining is handled with skill and consistency, ensuring high-quality parts every time.

Global Reach with Localized Support

Even though we serve customers nationwide, we provide localized support to keep shipping quick and communication clear. This approach means faster delivery and better service, so your projects stay on schedule.

Dedicated Customer Service

We offer direct access to knowledgeable staff for project consultation and updates. Whether you’re prototyping or running large batches, our team helps ensure your custom metal parts meet your exact needs without unnecessary delays.

Commitment to Sustainable CNC Tapping

At HYCNC, we focus on reducing waste during the metal tapping process. This sustainability effort benefits you, too, by supporting responsible manufacturing practices while maintaining competitive pricing and reliable turnaround times.

Choose HYCNC for precision, reliability, and service you can count on in all your sheet metal tapping projects.

Get Started with HYCNC’s Online Sheet Metal Tapping Service

Ready to bring your project to life with precision sheet metal tapping? Getting started with HYCNC is simple and fast.

- Upload Your Design: Use our easy online configurator to upload your CAD files—DXF, STEP, or STP formats accepted.

- Instant Quote and Preview: Get an immediate price estimate along with a 3D preview of your part to make sure everything looks right.

- Place Your Order: Approve your design and submit your order for rapid production. We handle everything from CNC tapping to finishing services.

We promise secure file handling to keep your designs safe and confidential. Plus, enjoy peace of mind with our satisfaction guarantee—we stand behind the quality of every part we deliver.

Visit HYCNC Online Configurator or contact our team at 1-800-HYCNC-USA for support or questions. Get your custom metal parts tapped and ready to go with industry-leading speed and precision.

HYCNC takes the hassle out of sheet metal tapping so you can focus on building your best product.