Struggling to achieve smooth, burr-free laser-cut metal parts? At HYCNC, our ceramic tumbling and deburring services deliver flawless finishes that enhance safety, aesthetics, and performance for your components.

As industry experts, we understand the challenges of working with laser-cut metals—sharp edges and burrs can slow down production and compromise quality. Drawing from years of CNC finishing experience, we’ve crafted a process that ensures your parts are ready for assembly, coating, or final use.

In this guide, you’ll discover how ceramic tumbling transforms your metal parts, why it’s the go-to solution for industries like aerospace and automotive, and how HYCNC delivers fast, cost-effective results.

Let’s get started!

Why Choose HYCNC for Ceramic Tumbling and Deburring Services for Laser Cut Metals

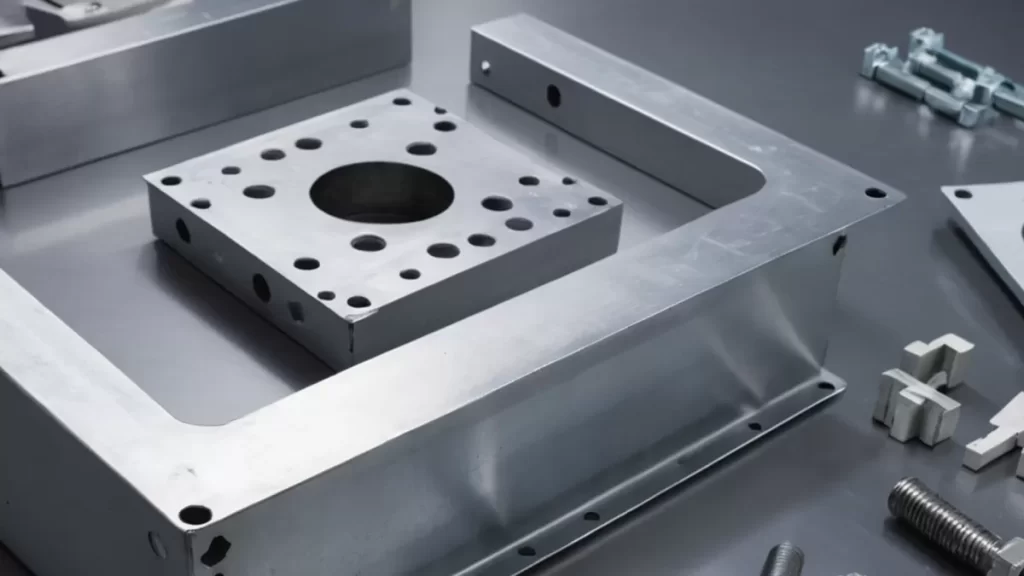

Ceramic tumbling and deburring are critical finishing processes that remove burrs and smooth the edges of laser-cut metal parts. These finishing steps ensure parts are safe to handle, visually appealing, and fully functional for their intended use. At HYCNC, we specialize in providing precision metal finishing through advanced ceramic tumbling and deburring techniques tailored for laser-cut metals.

With extensive experience serving industries such as manufacturing, automotive, and aerospace, HYCNC delivers parts that are safe, smooth, and ready to use right off the production line. Burr removal is not only crucial for preventing injuries during assembly and handling but also enhances the overall aesthetic quality and long-term reliability of your components.

Choose HYCNC for:

- Expert vibratory deburring for metals using ceramic media

- Industry-grade metal finishing services ensuring consistent, high-quality results

- Parts finished to exacting standards for critical applications

Trust HYCNC to help you achieve safer, cleaner, and more durable metal parts with efficient CNC deburring solutions designed to optimize your laser-cut metal processes.

What Is Ceramic Tumbling and Deburring for Laser Cut Metals

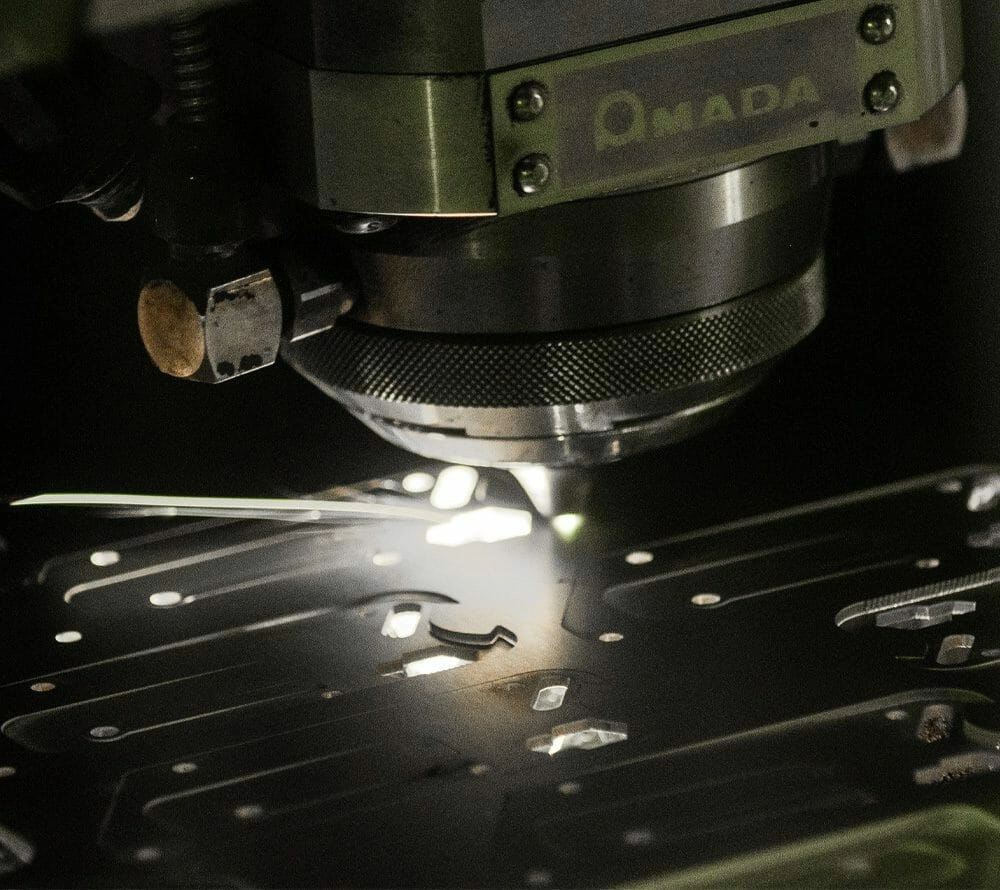

Ceramic tumbling and deburring is a vibratory or rotary finishing process that uses specially designed ceramic media to remove burrs, smooth sharp edges, and improve the surface finish of laser-cut metal parts. When metals like stainless steel, aluminum, brass, and titanium are laser cut, small rough edges and burrs are often left behind. These burrs can affect both the appearance and functionality of the parts.

Laser cutting creates burrs because the intense heat melts and sometimes vaporizes metal along the cut edges. This can leave behind jagged, sharp bits that need to be cleaned up for safety, aesthetic appeal, and proper fit in assemblies.

Ceramic tumbling is ideal for smoothing these edges because the ceramic media is hard enough to efficiently remove burrs but gentle enough to avoid damaging delicate parts. It also provides a uniform surface finish, which is important for downstream processes like painting or welding.

Tumbling vs Linear Deburring for Laser Cut Metals

-

Ceramic tumbling is best suited for smaller parts or batches where parts are placed in a vibratory or centrifugal tumbler along with the ceramic media. The media gently scrubs off burrs and polishes edges as the machine vibrates or spins.

-

Linear deburring, on the other hand, is a continuous process used for larger parts or sheet metal components. Parts move along a linear machine where ceramic media or brushes smooth edges in a controlled, automated way.

By choosing the right method, you get optimal burr removal, edge rounding, and finish quality tailored to your metal parts’ size and shape. This is why many rely on ceramic tumbling and deburring to enhance the quality of their laser-cut metals efficiently.

Benefits of HYCNC’s Ceramic Tumbling and Deburring Service for Laser Cut Metals

Choosing HYCNC for ceramic tumbling and deburring means getting more than just burr removal for laser-cut parts. Our process offers key advantages that make your metal parts safer, cleaner, and ready for the next steps in production.

Enhanced Safety

Removing sharp edges and burrs is crucial to prevent injuries during handling and assembly. Our ceramic tumbling uses precise vibratory deburring for metals that smooth out rough edges, reducing the risk of cuts or damage when working with stainless steel, aluminum, brass, titanium, and other metals.

Improved Aesthetics

Laser-cut metal polishing through ceramic media delivers a uniform, professional finish across your parts. This boosts the visual appeal of components—whether for automotive brackets, aerospace parts, or electronics housings—giving your products a consistent, high-quality look.

Better Downstream Processing

A clean, deburred surface is essential before painting, powder coating, or welding. Our tumbling prepares your parts by removing contaminants and smoothing edges, which improves coating adhesion and weld quality. This step saves you headaches in finishing and assembly down the line.

Efficiency and Cost-Effectiveness

Our automated ceramic tumbling and deburring solutions cut down on manual work and speed up production. This means faster turnaround times and lower labor costs compared to traditional hand deburring methods, helping your bottom line stay competitive.

Durability

Rounded edges from our tumbling process don’t just feel better—they also extend part longevity by improving resistance to wear and tear. Plus, the smoother surface helps coatings stick longer, keeping your metal parts protected and performing well in demanding environments.

With HYCNC’s precision metal finishing, you get a reliable, cost-effective way to prepare your laser-cut metals for whatever comes next.

HYCNC Capabilities for Ceramic Tumbling and Deburring Service for Laser Cut Metals

Materials We Handle

We work with a wide range of metals, including stainless steel, aluminum, brass, copper, titanium, and more. Whether your parts are made from common or specialty metals, we have the expertise and equipment to deliver precision metal finishing that meets your needs.

Part Sizes We Process

Our service covers parts from tiny components as small as 1 inch by 3 inches up to larger pieces measuring 24 inches by 46 inches. This means whether you’re working with small sheet metal parts or substantial assemblies, we can handle the job efficiently.

Advanced Tumbling Equipment

Using state-of-the-art vibratory and centrifugal tumblers, we tailor the tumbling and deburring process specifically to each material. This ensures consistent burr removal, smooth edges, and improved surface finishes that meet industrial metal tumbling standards.

Custom Ceramic Media Options

We offer customization of ceramic media to match your part’s requirements. Different media types and shapes help us control the edge rounding, polishing, and burr removal to fit your desired finish perfectly.

Rigorous Quality Control

Every part goes through strict quality inspection to ensure consistent and reliable finishes. Our QC process guarantees that your laser-cut metal parts arrive ready for immediate use or further manufacturing, maintaining high standards expected in industries like aerospace, automotive, and electronics.

With these capabilities, HYCNC’s ceramic tumbling and deburring service for laser cut metals is designed to give you smooth, safe, and polished parts no matter the size or material.

Industries We Serve for Ceramic Tumbling and Deburring of Laser Cut Metals

At HYCNC, we proudly support a wide range of industries with ceramic tumbling and deburring services tailored for laser-cut metals. Our expertise covers:

- Aerospace – precision deburring of critical components to meet strict safety and performance standards

- Automotive – smoothing brackets, panels, and parts for better durability and finish

- Electronics – finishing small metal housings and connectors for reliable performance

- Medical devices – ensuring burr-free parts where smooth, safe edges are essential

- General manufacturing – deburring and edge rounding for various metal products to improve fit and function

We handle high-precision, high-volume orders with consistency and speed, making us a trusted partner for both small runs and large-scale projects.

Whether you need vibratory deburring for metals, industrial metal tumbling, or sheet metal deburring services, we’ve got the right setup and experience to deliver smooth, safe, and ready-to-use parts every time.

Why HYCNC Stands Out for Ceramic Tumbling and Deburring Service for Laser Cut Metals

At HYCNC, we know what matters most when it comes to ceramic tumbling and deburring for your laser-cut metal parts. Here’s why we stand out in the US metal finishing market:

-

Fast turnaround times

We prioritize quick, reliable service, so your parts are ready when you need them. This means less downtime and faster project completion.

-

Competitive pricing with instant quotes

Our online portal gives you instant, transparent pricing — no surprises, no waiting. This helps you budget efficiently and plan your production with confidence.

-

Local service reduces shipping costs

Serving clients across the US, our regional locations keep your shipping expenses low and ensure parts get to you safely and on time.

-

Expert team with decades of CNC and finishing experience

Our skilled technicians understand the nuances of vibratory deburring for metals and precision metal finishing. We deliver consistent, high-quality results for all materials including stainless steel, aluminum, brass, and titanium.

-

Commitment to sustainability

We focus on efficient, low-waste processes that minimize environmental impact, so you can feel good about choosing a responsible industrial metal tumbling partner.

By combining expertise, speed, affordability, and eco-friendly practices, HYCNC delivers a top-tier ceramic tumbling and deburring service for laser cut metals that meets the high standards of today’s manufacturing, automotive, and aerospace industries.

How It Works Ordering Ceramic Tumbling and Deburring Service with HYCNC

At HYCNC, we make ordering ceramic tumbling and deburring services for laser-cut metals simple and fast. Here’s how it works:

Easy Step-by-Step Process

-

Upload Your Files

Start by uploading your DXF or STEP files through our online platform. This is the best way to share your exact part designs for precision metal finishing.

-

Choose Your Deburring Options

Select the type of finishing you need, whether it’s vibratory deburring for metals, edge rounding, or specialized ceramic media for deburring laser-cut parts.

-

Get an Instant Quote

You’ll receive a quick, transparent price right away. No waiting, no guesswork.

-

Approve and Place Your Order

Review the quote and approve your job. Once confirmed, our expert team starts processing your parts with state-of-the-art tumbling and deburring equipment.

-

Receive Finished Parts

Parts arrive ready to use with burrs removed, edges smoothed, and surfaces polished, suitable for manufacturing, automotive, aerospace, and more.

User-Friendly Platform and Support

Our easy-to-navigate online portal is designed for your convenience, letting you track orders and communicate easily. Plus, our responsive customer support team is always ready to help with any questions.

Additional Metal Finishing Services

Beyond ceramic tumbling and deburring, HYCNC also offers:

- CNC laser cutting

- Bending and forming

- Surface plating and coating

This lets you streamline your metal finishing process with one trusted, local US-based provider.

With HYCNC, you save time and simplify your workflow—get safe, smooth, and finished parts delivered on schedule and on budget.

FAQs About Ceramic Tumbling and Deburring for Laser Cut Metals

What types of metals can be deburred with ceramic tumbling

Ceramic tumbling works well on a variety of metals, including stainless steel, aluminum, brass, copper, and titanium. These materials respond well to ceramic media, which effectively removes burrs and smooths edges without damaging the part. Whether your parts are laser cut or CNC machined, ceramic tumbling is a solid choice for precision metal finishing.

How long does the ceramic tumbling and deburring process take

The process duration depends on the part size, metal type, and burr severity. Small parts typically take a few hours, while larger or more complex components might need longer. At HYCNC, we optimize tumbling time to balance efficiency with the best surface finish, ensuring your parts are ready on schedule.

How does ceramic tumbling impact part appearance

Ceramic tumbling improves the surface finish by smoothing rough edges and removing unwanted burrs. This results in a more uniform, professional look that enhances both the aesthetics and functionality of laser-cut metal parts. It also prepares surfaces for better coating adhesion and downstream processes like painting or powder coating.

Are there size limitations for ceramic tumbling

Yes, size does matter. Ceramic tumbling is ideal for smaller to medium-sized parts, typically ranging from around 1 inch by 3 inches up to about 24 inches by 46 inches. For larger parts, we offer customized linear deburring or other finishing solutions to match your needs.

Can HYCNC handle high-volume ceramic tumbling orders

Absolutely. We have state-of-the-art vibratory and centrifugal tumblers designed for both small batches and large-scale production runs. Our automated processes help reduce manual labor costs and speed up turnaround, making us a reliable partner for high-volume deburring and finishing.

For more on preparing your designs before finishing, check out our guide on exporting vector files for laser cutting.

If you’re looking for additional CNC machining support, our CNC machine shop services might be helpful too.