What Is Laser Cutting Understanding the Technology and Its Advantages

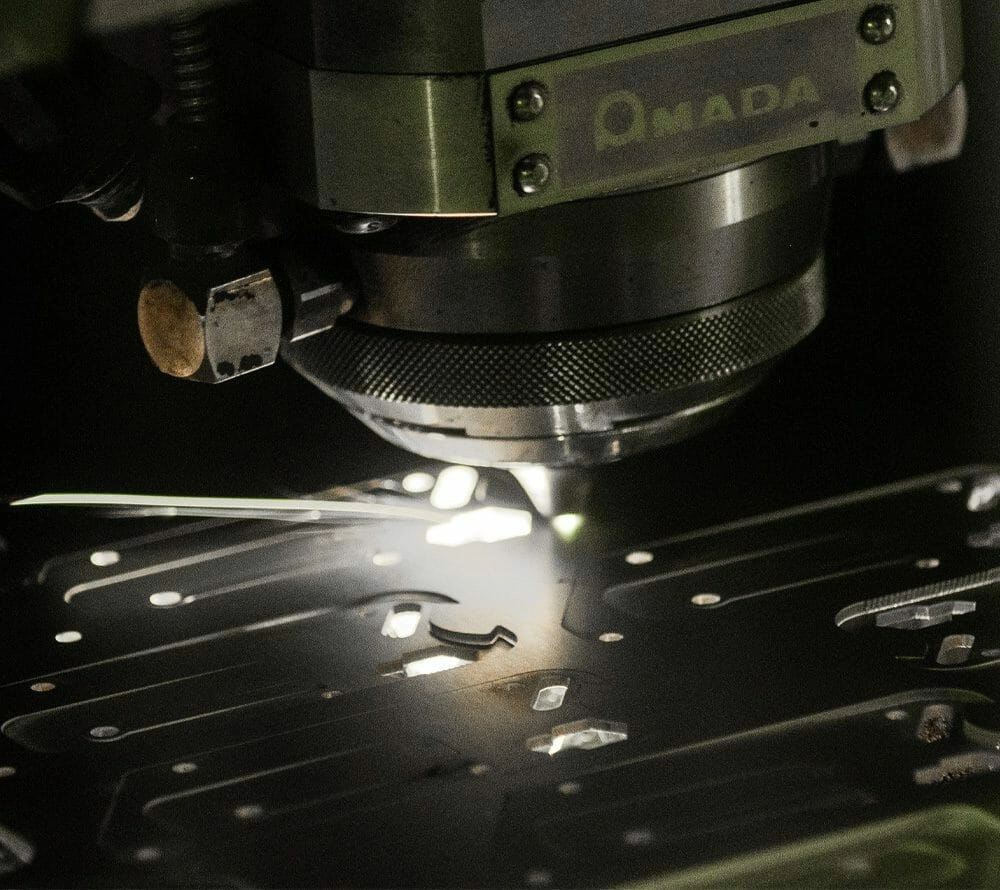

Laser cutting is a precise manufacturing process that uses a highly focused laser beam to cut materials. This focused beam melts, burns, vaporizes, or blows away material, resulting in clean, accurate cuts. Laser cutting is typically controlled by CNC (Computer Numerical Control) systems, allowing for automated, repeatable, and complex cutting operations.

How Laser Cutting Works

- A high-powered laser beam is directed onto the material’s surface.

- The beam’s heat instantly melts or vaporizes the target area.

- A gas (like oxygen or nitrogen) blows away the molten material, leaving a clean edge.

- The CNC system precisely controls the laser’s path, speed, and intensity to achieve tight tolerances and detailed designs.

Types of Lasers Used in Laser Cutting

Several laser types are popular due to their unique strengths:

- CO2 Lasers: Ideal for cutting non-metals like acrylic, wood, and fabric as well as thin metals. Known for clean cuts and versatility.

- Fiber Lasers: Perfect for metals such as steel, aluminum, brass, and titanium. Fiber lasers offer high speed, efficiency, and excellent precision.

- Crystal Lasers (Nd:YAG): Used mainly for marking and micro-cutting tasks needing ultra-fine detail.

Each laser type is suited for different materials and thicknesses, giving manufacturers flexibility depending on their project needs.

Laser Cutting vs Traditional Cutting Methods

Laser cutting surpasses older methods like plasma cutting and waterjet cutting in multiple ways:

- Higher precision and cleaner edges with minimal burrs.

- Faster processing speeds leading to increased productivity in mass production.

- Ability to cut intricate shapes and fine details that are difficult for traditional tools.

- Less material distortion due to localized heating.

- Reduced need for secondary finishing.

Why Laser Cutting Is Preferred in Modern Manufacturing

Increasingly, industries rely on laser cutting because it offers:

- Superior accuracy and repeatability, ensuring high-quality output every time.

- Versatility across a wide range of materials from metals to plastics and textiles.

- Speed and automation support for large-scale production without sacrificing detail.

- Environmentally friendly processes with minimal waste and cleaner operation.

- The ability to rapidly prototype and modify designs with ease.

By combining advanced CNC laser cutting services with different laser technologies, manufacturers can meet demanding production goals while maintaining cost effectiveness and flexibility.

If you’re looking for a cutting solution that delivers precision, speed, and adaptability, laser cutting is the smart choice for today’s manufacturing needs.

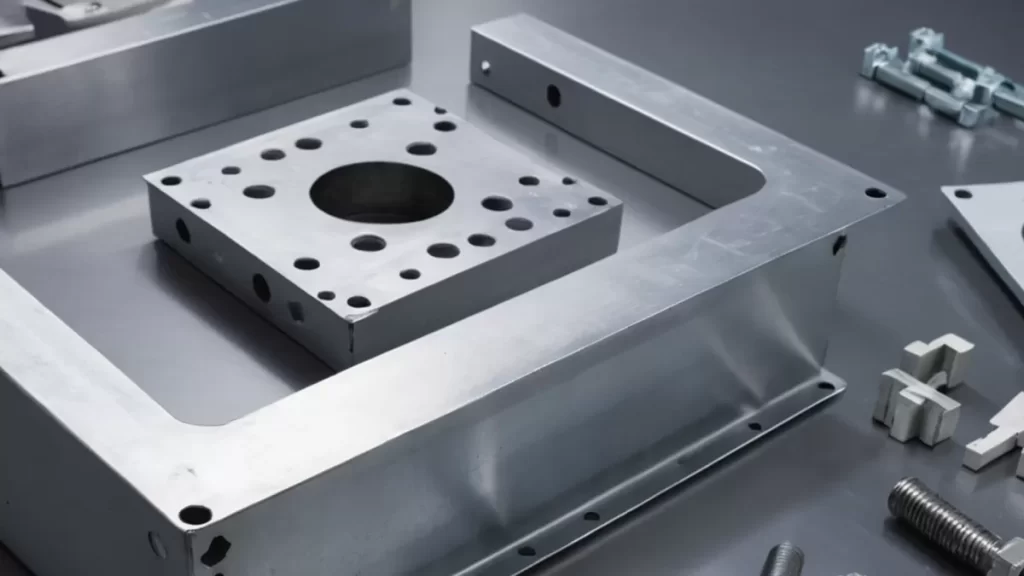

Key Capabilities of Laser Cutting

Laser cutting offers a range of powerful capabilities that make it a top choice for modern manufacturing and custom projects. Here’s what makes it stand out:

Precision and Accuracy

- Tight tolerances: Laser cutting delivers extremely precise cuts, perfect for parts that need to fit just right.

- Clean edges: Expect smooth, burr-free finishes that often reduce or eliminate additional finishing work.

- Consistent results: CNC laser cutting technology ensures each cut meets exact specifications every time.

Versatility in Materials

Laser cutting works on a wide variety of materials, making it incredibly adaptable:

- Metals: Steel, aluminum, titanium, brass, and more.

- Non-metals: Acrylic, wood, rubber, textiles, and other materials.

- This versatility opens doors to many industries, from automotive to fashion.

Complex Geometries

- Intricate designs: Cuts can handle fine details and complicated shapes with ease.

- Minimal kerf: The cutting width is very narrow, which means less material loss and sharper lines.

- 2D shapes and engravings: Great for both cutting flat parts and adding detailed engravings or markings.

High Speed and Efficiency

- Faster production: Compared to traditional cutting, laser cutting completes jobs quickly.

- Automation friendly: Ideal for high-volume runs where speed and repeatability count.

- Helps businesses meet tight deadlines without compromising quality.

Minimal Material Waste

- Optimized cutting paths: CNC programming maximizes material use by nesting parts closely.

- Cost-effective: Less wasted material means lower costs.

- Environmentally friendly: Efficient use of materials reduces environmental impact.

Scalability

- From prototypes to mass production: Laser cutting suits both one-off jobs and large-scale manufacturing.

- Flexible solutions: Quickly adjust batch sizes without changing processes.

- Perfect for growing businesses needing adaptable production options.

Laser cutting’s key capabilities make it a smart, reliable choice for many US manufacturers and fabricators looking for quality, speed, and versatility all in one package.

Industry Applications of Laser Cutting Precision and Versatility

Laser cutting is a game-changer across many industries thanks to its precision, speed, and flexibility. Here’s how different fields benefit from this technology and how HYCNC customizes laser cutting services to meet those needs.

Automotive Precision Components and Body Panels

In the automotive world, laser cutting handles precision components, body panels, and brackets with tight tolerances. Whether it’s cutting steel or aluminum, laser cutting offers clean edges and reduces the need for secondary finishing. This means faster turnaround times for manufacturers building cars or trucks.

Aerospace Lightweight Materials and Complex Parts

The aerospace sector relies heavily on lightweight metals like titanium and aluminum. Laser cutting helps produce complex parts with minimal waste and high accuracy, crucial for components exposed to extreme conditions. HYCNC’s expertise ensures compliance with aerospace standards while keeping production efficient.

Electronics Microcuts and PCB Housings

For electronics, laser cutting delivers microscopic cuts perfect for printed circuit boards (PCBs) and delicate housings. The ability to cut fine lines and intricate shapes without damaging sensitive materials makes laser cutting ideal for this industry.

Medical Devices Biocompatible Implants and Surgical Tools

Laser technology allows precision cutting of biocompatible metals and plastics, which is necessary for medical devices like implants and surgical tools. Clean cuts and smooth edges are vital for safety and performance, and HYCNC’s laser cutting services excel in meeting these strict requirements.

Fashion and Textiles Intricate Fabric Patterns

In fashion and textiles, laser cutting supports detailed fabric patterns and custom designs that would be difficult or slow with traditional cutting. From rubber to delicate textiles, laser cutting opens new creative possibilities.

How HYCNC Tailors Laser Cutting to Industry Needs

At HYCNC, we understand that each industry demands different things from laser cutting. That’s why we offer:

- Custom material handling for metals, plastics, and textiles

- Advanced CNC laser cutting equipment like 12kW fiber lasers for high precision

- Flexible production options, from prototypes to large-scale runs

- Collaborative project management to ensure specs are met on time

Our local service in the US means faster communication and quicker project turnaround, making us the trusted partner for your laser cutting needs across various industries.

Advantages of Laser Cutting with HYCNC

When you choose HYCNC for your laser cutting needs, you get reliable, high-quality results every time. Here’s what sets us apart:

High Quality Output and Minimal Finishing

- Clean, precise cuts mean less post-processing.

- Edges are smooth with burr-free finishes, saving you time and money.

- Ideal for projects that demand exacting standards, whether small or large scale.

Cost-Effective for All Project Sizes

- Whether you’re running a low volume prototype or a big production batch, we tailor our services to keep costs competitive.

- Our efficient processes minimize material waste, which means greater savings for you.

Rapid Prototyping and Quick Turnaround

- Need fast results? Our streamlined workflow ensures quick project completion without sacrificing quality.

- Perfect when you need to move from design to production in record time.

Advanced CAD CAM Integration for Custom Designs

- We work directly from your digital files using state-of-the-art CAD CAM software.

- This ensures accurate, repeatable cuts and allows for complex, custom designs with ease.

State-of-the-Art Equipment

- Equipped with powerful 12kW fiber lasers, HYCNC handles a wide range of materials and thicknesses.

- Our machines deliver precision cutting, high speed, and consistent quality, giving you a reliable partner in modern manufacturing.

By combining these advantages, HYCNC ensures you get the best out of laser cutting with precision, speed, and cost efficiency tailored to the American market.

Limitations and Considerations of Laser Cutting with HYCNC

While laser cutting offers many advantages, it’s important to understand some limitations, especially for the U.S. market where precision and cost-efficiency are key.

Material Thickness Constraints and Challenges

- Thick metals like heavy steel or titanium can be tougher to cut cleanly with laser, requiring slower speeds or multiple passes.

- Laser cutting excels with thin to medium thickness materials but may not be the best choice for parts over a certain thickness where plasma or waterjet might make more sense.

- HYCNC specializes in balancing these limits by selecting the right laser type (fiber, CO2) and adjusting settings for optimal cuts on various metals.

Energy Consumption and Operational Costs

- Laser cutting machines consume a considerable amount of power, especially high-powered fiber lasers.

- This can increase operational costs, which are important to consider on larger production runs.

- At HYCNC, we optimize machine usage and cutting paths to keep energy use efficient, helping you save money while maintaining quality.

Need for Skilled Operators

- Laser cutting demands trained professionals to manage machine settings, material handling, and quality control.

- Improper operation can lead to wasted materials and machine downtime.

- HYCNC’s team is highly trained and experienced, minimizing risks and ensuring top-notch results every time.

In short, material thickness, energy costs, and skilled operation are the biggest considerations, but with HYCNC’s expertise and state-of-the-art equipment, these challenges are well-managed for consistent, high-quality laser cutting services.

Why Choose HYCNC for Laser Cutting Services

When it comes to CNC laser cutting services, HYCNC stands out for its advanced capabilities and customer-focused approach tailored to meet the needs of manufacturers across the United States.

Advanced Laser Cutting Capabilities

HYCNC delivers precision and consistency using state-of-the-art equipment, including high-power fiber lasers capable of cutting a wide range of materials from steel and aluminum to acrylic and textiles. Our machines support intricate designs with minimal kerf, ensuring clean, burr-free edges every time.

Commitment to Quality and Precision

We prioritize quality and accuracy in every project, no matter the size. Our experienced team monitors each cut closely, ensuring your parts meet tight tolerances. This commitment results in fewer adjustments downstream and faster project completion.

Customer Satisfaction and Local Service

HYCNC is proud to offer local laser cutting services with quick turnaround times suited for businesses across various US regions. We understand the importance of reliable support and personalized service, keeping your project on track from start to finish.

Instant Quoting and Seamless Project Management

To make partnering with us fast and easy, we provide instant quoting tools and streamline the entire process through efficient project management. This transparency saves you time and helps keep budgets tight.

Proven Success with Real Results

Our track record includes successful projects for automotive, aerospace, electronics, and medical device clients. For example, a recent job involved producing high-precision titanium brackets for aerospace applications, delivered ahead of schedule with top-tier quality — a testament to our capabilities.

If you want a partner who combines technical expertise with local responsiveness, choose HYCNC for your laser cutting needs.

For more on how we handle different materials and laser cutting processes, check out our detailed guides on laser cutting steel and common laser processing methods.

FAQs About HYCNC Laser Cutting Capabilities

What Materials Can HYCNC Cut With Laser Cutting

HYCNC’s laser cutting services handle a wide range of materials including metals like steel, aluminum, titanium, and brass, plus non-metals such as acrylic, wood, rubber, and textiles. This versatility means whether you need precise cuts for industrial parts or intricate designs for creative projects, HYCNC has you covered.

How Precise Is HYCNC Laser Cutting Service

HYCNC delivers high precision and tight tolerances with clean, burr-free edges thanks to advanced fiber and CO2 laser technology. This ensures your parts fit perfectly without extra finishing. Our laser cutting precision supports detailed engravings and complex shapes, ideal for prototype or high-volume production.

Industries Served by HYCNC With Laser Cutting

We serve a broad range of sectors including:

- Automotive components

- Aerospace lightweight parts

- Electronics housings and PCBs

- Medical devices and implants

- Fashion and textiles for custom patterns

No matter the industry, HYCNC offers tailored solutions that meet specific quality and material needs.

Comparison of Laser Cutting to Other CNC Methods

Compared to plasma or waterjet cutting, laser cutting at HYCNC stands out for:

- Superior accuracy and edge quality

- Faster production speeds

- Less material waste for cost-effectiveness

- Capability to handle detailed and complex designs

To learn more about differences between cutting methods, check out our guide on CNC router vs laser cut.

Handling Large Scale Laser Cutting Projects

HYCNC is equipped for projects of all sizes — from single prototypes to large-scale manufacturing runs. Our automation and powerful 12kW fiber lasers ensure fast turnaround without compromising quality. Plus, our streamlined quoting and project management make scaling easy and efficient.

For tips on optimizing your designs for laser cutting, you can also visit our blog on best laser cutting design software.